Abstract

The effects of low-cost Thai leucoxene mineral (LM) at different concentrations (10, 20, 30, 40, 50, and 60 mg/L) on the growth and antibacterial properties of Chrysanthemum indium L. cuttings under in vitro were evaluated. The primary chemical composition of LM was approximately 86% titanium dioxide (TiO2), as determined by dispersive X-ray spectroscopy. The crystalline structure, shape, and size were investigated by X-ray diffraction and scanning electron microscopy. LM at 40 and 50 mg/L significantly increased plant height, leaf number, node number, and fresh and dry weight. These growth-promoting properties were accompanied by improved chlorophyll and carotenoid contents and antioxidant enzyme activities and reduced malondialdehyde levels. Additionally, LM treatment at 40 and 50 mg/L had positive effects on antibacterial activity, as indicated by the lowest minimum inhibitory concentration (MIC) and minimum bactericidal concentration (MBC) values. The high levels of phenolic compounds in the plants contributed to the MIC and MBC values. In conclusion, these findings provide evidence for the effectiveness of LM in enhancing the growth of Chrysanthemum plants in in vitro culture and improving their antibacterial abilities.

Similar content being viewed by others

Introduction

Chrysanthemum indium L. (C. indium) is in the Asteraceae family and is an aromatic and medicinal plant generally found in Thailand, Korea, Japan, and China1,2. C. indium is also a highly valued ornamental crop worldwide 3. This flower holds cultural significance, with billions of floral stems sold annually. C. indium is cultivated in various colors, sizes, and forms of composite Chrysanthemum flowers by incorporating different combinations, concentrations, and types of anthocyanins, carotenoids, and chlorophyll2. In addition, dried C. indium (especially the flowers and buds) is regularly applied to treat eye diseases and is used for the preparation of traditional tea1. Furthermore, C. indium extracts have been used to treat various conditions, such as hypertension and respiratory and inflammatory diseases4. This plant is also known for its various health benefits, including antimicrobial, antibacterial, and anticancer effects5.

The propagation of C. indium using seeds is challenging due to its long dormancy period and low germination rate6. Various factors, including the type of explant, plant size, plant growth regulators, and temperature, can contribute to its slow development or failure to germinate, affecting regularity. Modern biological methods such as micropropagation and mutation breeding via in vitro conditions have been developed to produce higher yields of C. indium. Generally, the cultivation of C. indium is performed by using shoot cuttings and root suckers2. Shoot cutting is a popular and simple method of in vitro propagation because it has high natural mutation rates and is self-incompatible7,8,9. This method also maintains the characteristics and qualities of the mother plant10. Nevertheless, this strategy has limitations, including a diminished reproduction rate, a substandard seedling quality, an extended reproduction time, seasonal limitations, limited genetic diversity, and the inability to circumvent cross-incompatibility. Moreover, cuttings frequently sourced from parent plants may succumb to viral infections and degradation, consequently increasing production costs2. Thus, enhancing the yield of C. indium in tissue culture using new techniques has become a challenging problem for scientists.

Several studies have investigated the use of tissue culture for the large-scale propagation of Chrysanthemum morifolium (C. morifolium) by exploring novel regeneration pathways11,12. Establishing effective strategies to prevent microbial contamination in culture media is crucial. Instead of relying solely on physical sterilization methods such as autoclaving, chemical agents, nanoparticles, or plant extracts, either alone or in combination with autoclaving, can be considered13. Furthermore, explants cultivated in vitro serve as exceptionally suitable materials for irradiation purposes. By utilizing in vitro cultures within a confined, disease- and pest-free environment, a substantial quantity of irradiated explants can be accommodated in a limited space. This approach ensures more efficient regeneration than in vivo conditions, enhances the likelihood of obtaining mutated plants, and facilitates a significant acceleration of all stages within the breeding program. In a previous study in which C. morifolium was cultured in vitro at a low concentration of 6-benzylaminopurine effectively enhanced the growth of roots and shoots14. Interactions between cytokines and auxins are also considered to induce the roots and shoots of C. indium plants15.

Titanium dioxide (TiO2) and TiO2-based materials have been widely used in a variety of applications, such as semiconductor materials, water treatment materials16, antimicrobial activity17, and agriculture18. TiO2 nanoparticles (TiO2 NPs) are applied to plants to enhance their growth and performance. TiO2 NPs affect plant morphology, chlorophyll formation, Rubisco enzyme activity, and photosynthesis, improving plant growth. The major benefit of TiO2 NPs is their ability to produce reactive oxygen species (ROS)19, which play an important role in plant development. TiO2 NPs induce chloroplasts in photosynthetic organisms, and since chloroplasts are one of the main establishments that produce ROS in plants19, changes in ROS induced by TiO2 NPs might be related to changes in chloroplast function. Various studies have reported that TiO2 NPs can affect plants. For example, Gohari et al.20 reported improvements in the growth, chlorophyll content, carotenoid content, and antioxidant enzyme activity of Dracocephalum moldavica (D. moldavica) with increasing TiO2 NP concentrations. Mustafa et al.21 reported that TiO2 NPs improved bioactive compounds in wheat plants. The combination of TiO2 NPs and light intensity could enhance the biomass and leaf thickness of radish, as reported by Vatankhah et al22. In recent years, TiO2 nanoparticles have garnered attention in C. indium cuttings under in vitro culture because TiO2 increases the growth efficiency of plants23. In addition, TiO2 NPs can promote the growth of many plants, such as Mentha piperita L. 24, Vicia faba 25, greenhouse-grown cut roses26 and Sesamum indicum L.27. Although TiO2 NPs positively affect plant growth, they are expensive due to their difficult synthesis process.

Leucoxene is a versatile mineral that mainly comprises TiO2 and impurities such as iron oxide (Fe2O3), silicon dioxide (SiO2), aluminum oxide (Al2O3), and zirconium dioxide (ZrO2). Because of its high TiO2 content, leucoxene has been used as a starting material to synthesize TiO2 NPs for several applications, such as protective photocatalysts, UV absorbers, and pigments in paints and plastics28. The synthesis of TiO2 NPs is complicated, and various techniques, such as hydrothermal technology, electrodeposition, and electrospinning, are used29. These processes are expensive and time-consuming.

As outlined in the literature, TiO2 NPs have been widely used in agricultural applications; however, the direct impact of leucoxene mineral (LM) on plant germination has never been investigated. Here, the objective of this study was to use a low-cost natural LM (< 0.5 USD/kg) instead of TiO2 NPs to study its impact on the in vitro growth, antioxidant capacity, and antibacterial properties of C. indium. Scanning electron microscopy was used to determine the shape and size of LM, and X-ray diffraction and dispersive X-ray spectroscopy were used to determine its crystalline structure and chemical composition. The effects of different LM concentrations (10, 20, 30, 40, 50, and 60 mg/L) on the morphophysiological and biochemical characteristics of C. indium were evaluated and compared to those of a control group. Furthermore, the phenolic compound content, flavonoid content, DPPH radical scavenging capacity, and antibacterial activity of untreated and LM-treated C. indium were observed.

Materials and methods

Preparation of LM

Sakorn Minerals Co., Ltd. supplied a low-cost natural LM from Prachuap Khiri Khan Province (12.1712° N, 99.8125° E), Thailand. To prepare a powder, the natural LM was ball milled at 250 rpm for 12 min. X-ray diffraction (XRD, PANalytical X'Pert PRO MRD) and dispersive X-ray spectrometry (EDS, model INCA-350) were used to analyze the crystalline structure and chemical composition of the mineral powder. Scanning electron microscopy (SEM; model JSM-5410LV) was used to determine the shape and size of the LM particles28.

Chemical reagents

Potassium phosphate, polyvinylpyrrolidone (PVP), hydrogen peroxide, 2,2-diphenyl-1-picrylhydrazyl (DPPH), sodium phosphate, methionine, riboflavin, ethylenediaminetetraacetic acid (EDTA), nitroblue tetrazolium (NBT), ethanol, Folin–Ciocalteu reagent, gallic acid, malondialdehyde kits, dimethyl sulfoxide, and sodium carbonate were purchased from Sigma Aldrich (St. Louis, MO, USA).

Plant materials

The plant materials were cultured in a field at the Thailand Institute of Scientific and Technological Research (TISTR). Samples were collected from naturally growing C. indicum plants between November and December 202123.

Stem cutting and cultivation of C. indicum

C. indicum cuttings were cut to an average length of 1 cm and a diameter of 0.2 cm. These cuttings were subsequently grown in Murashige and Skoog30 media supplemented with different concentrations of LM (10–60 mg/L), followed by sucrose (30 mg/L) and Gelrite (3 mg/L). A control group with no TiO2 NPs was used. The final pH of the medium was adjusted to 5.7. C. indicum was cultured under a light–dark cycle of 16/8 h at 25 ± 2 °C for 8 weeks. The light intensity was set at 60 ± 5 µmol/m2/s using fluorescent lights. The characteristics of C. indicum were measured every 2 weeks.

Experimental design

One treatment was conducted on ten cuttings, with six replicates per treatment. Plant height and root, leaf, and node numbers were recorded every two weeks. The fresh shoot weight, root weight, and root length were recorded on the eighth week of cultivation. To determine the dry shoot and root weights, the shoots and roots were dried in a hot air oven at 90 °C for 24 h23.

Total chlorophyll and carotenoid content measurements

Total chlorophyll, chlorophyll a (Chl a), chlorophyll b (Chl b), and total carotenoid contents were determined using a previously described method31. A 50-mg dry leaf sample was mixed with 5 mL of dimethyl sulfoxide (DMSO). The mixture was stored in the dark at 60 °C until the tissue became colorless. The absorbance of the mixture was determined at 480, 647, and 664 nm using a spectrophotometer, with DMSO as the blank. The pigment content was calculated using the following equations:

where DW is the dry weight.

Antioxidant enzyme activity measurement

Extraction

One gram of plant leaves was homogenized in potassium phosphate buffer (pH 6.8, 10 mM) containing 1% polyvinylpyrrolidone (PVP) using a magnetic stirrer for 10 min. After centrifugation at 6,000 rpm for 20 min, the supernatant was retained to determine ascorbate peroxidase (APX)32, catalase (CAT)32, and superoxide dismutase (SOD) activities32.

Ascorbate peroxidase (APX) activity

The activity of APX was evaluated following a previously described method32. The enzyme extract was added to an assay mixture consisting of 250 μL of 1 mM ascorbate, 250 μL of potassium phosphate buffer, 250 μL of 0.4 mM EDTA, 190 μL of distilled water, and 250 μL of H2O2 (10 mM). The absorbance of the sample was determined at 290 nm using a spectrophotometer. An extinction coefficient of 2.8 cm−1 mmol−1 was used to calculate the results.

Catalase activity

CAT activity was determined using a calorimetric method32. Three micrograms of crude extract was mixed with 20 mM sodium phosphate buffer (pH 7.5) and 6 mM H2O2. The final volume of the mixture was one milliliter. The activity of CAT was measured by the decreasing rate of H2O2 at 240 nm for 3 min using a spectrophotometer. The extinction coefficient was 40 M–1 cm–1. The results are expressed as mM per min per mg of protein (mM min-1 mg-1 of protein).

Superoxide dismutase (SOD) activity

SOD activity was evaluated by measuring the inhibition of the photochemical reduction of nitroblue tetrazolium (NBT)32. Specifically, 50 mL of crude extract was added to the reaction mixture, which was prepared with 130 mM methionine, 0.1 mM ethylenediaminetetraacetic acid (EDTA), 50 mM phosphate buffer (pH 7.8), 0.02 mM riboflavin, and 0.75 mM NBT. The final volume was 3 mL. The mixture was placed under fluorescent lamps (5,000 lx) for 15 min. Then, the absorbance of the mixture was determined at 560 nm using a spectrophotometer. The value of the enzyme required to inhibit NBT photoreduction by 50% was considered one unit of SOD.

Malondialdehyde level measurement

Lipid peroxidation was monitored by measuring malondialdehyde (MDA) levels according to a previous study33. For extraction, 5 mL of 100 g/L trichloroacetic acid was added to fresh tissue (1 g). After centrifugation at 9000 rpm for 20 min at 4 °C, 3 mL of the supernatant was mixed with 3 mL of 0.67% thiobarbituric acid (TBA). The mixture was incubated at 100 °C for 20 min and then placed on ice to cool to room temperature. The absorbance of the samples at 450, 532, and 600 nm was measured with a spectrophotometer to determine the MDA concentration. The results are expressed as nmol/L fresh weight (nmol/L FW).

Total phenolic content (TPC) measurement

The TPC was estimated using the Folin–Ciocalteu colorimetric method33. The reference standard was gallic acid. The sample extract was diluted with 80% ethanol at a ratio of 1:5. Distilled water (0.5 mL) was mixed with 125 μL of Folin–Ciocalteu reagent (10% w/v), followed by 125 μL of the sample. The mixture was left at room temperature for 6 min, after which 1.25 mL of sodium carbonate solution (7%) was added. The absorbance of the sample was evaluated at 760 nm. The results are expressed as mg of gallic acid equivalents per gram of extract (mg GAE/g extract).

Total flavonoid content (TFC) measurement

The TFC was measured by the colorimeter method33. A total of 0.5 mL of plant extract was added to 1.5 mL of methanol, potassium acetate, 1 M 10% aluminum chloride, and 2.8 mL of distilled water. After vortexing and incubation in darkness for 30 min, the absorbance of the solution was evaluated at 415 nm using a microplate reader (SpectraMax, Model i3x Multi-Mode). The reference standard was quercetin; thus, the results are expressed as milligrams of quercetin equivalent per gram of extract (mg QUE/g extract).

Antioxidant activity measurement

DPPH radical scavenging activity was evaluated to assess antioxidant activity33. A 20 µg/mL plant extract was added to 1 mM DPPH and 4 mL of methanol. The mixture was centrifuged and kept in darkness for 30 min. The absorbance was then determined at 517 nm, and the result was expressed as a percentage of DPPH radical inhibition using the following equation:

The reference standard was ascorbic acid; thus, the results are expressed as mg ascorbic acid equivalents antioxidant capacity in g of extract (mg AEAC/g extract).

Measurement of the minimum inhibitory concentration (MIC) and minimum bactericidal concentration (MBC)

One gram of dry sample was dissolved in 100 mL of ethanol. The extraction was performed at room temperature for three days. Filter paper (Whatman No. 1) was used to filter the mixture. The aqueous extract was concentrated in a rotary evaporator at 40 °C. The extraction yield was calculated for the obtained residue.

The 0.5 McFarland standard (1.5 × 108 CFU/mL) of three bacterial pathogens was diluted with the extract at a 1:200 ratio. Fifty microliters of nutrient broth was added. After incubating at 37 °C for 24 h, ten microliters of 0.18% resazurin was added; subsequently, the mixture was incubated for 2 h. The MIC was determined by the minimum bacterial number and calculated following previously described methods34.

The MIC was then subcultured on Mueller–Hinton agar plates. To determine the MBC, the mixture was incubated at 37 °C for 24 h. The MBC achieved the lowest concentration associated with the flower extract, killing > 99.9% of the initial bacteria35.

Data analysis

This study included six replicates (n = 6) for plant growth parameters and three replicates (n = 3) for chlorophyll and carotenoid contents, antioxidant enzyme activity, MDA content, phenolic content, flavonoid content, and DPPH radical scavenging capacity. The obtained data are presented as the mean value and standard deviation. One-way analysis of variance (ANOVA) with Duncan's multiple range test36 (p < 0.05) was performed to test the significance of the results using SPSS software, version 26.0.

Results and discussion

Characterization of leucoxene mineral

To study the morphology, size and composition of LM, SEM and EDS were performed. Figure 1 shows the SEM and EDS images of the natural LM after ball milling at 250 rpm for 12 min. The natural LM is granular, with average particle sizes ranging from 1 to 40 µm (Fig. 1a). Figure 1b presents the EDS spectrum of the natural LM. In the selected area, the EDS spectrum shows a strong signal of the titanium area and ensures the formation of titanium dioxide. Table 1 displays the chemical composition of the natural LM as detected by EDS, which indicates that it consists of 85.97% TiO2, 5.82% FeO, 3.82% SiO2, 2.06% Al2O3, 1.37% vanadium oxide (V2O5), and 0.96% ZrO2. Figure 2 shows the XRD pattern of the natural LM, which reveals its crystalline structure. The XRD patterns show strong diffraction peaks at approximately 27°, 36°, 41°, 44° and 64°, indicating that TiO2 is present in the rutile (R) structure. In addition, a dominant diffraction peak is also observed at approximately 25°, which indicates that TiO2 is in the anatase (A) phase. The EDS and XRD results correspond to those of a previous report29. Typically, the micro- or nanosized TiO2 containing the anatase and rutile phases has been reported to be an efficient photocatalyst that is able to produce ROS20. Hence, increasing concentrations of LM led to a direct increase in plant growth.

The leucoxene mineral modulates plant growth

Table 2 displays the effect of varying concentrations of LM on the growth of C. indicum cuttings in in vitro culture over a period of 8 weeks. The results showed that the height of C. indicum plants treated with 40 mg/L LM was significantly greater than that of the control plants at the second and fourth weeks, with increases of 35.71 and 34.49%, respectively. However, there were no significant differences between the control plants and plants treated with 50 or 60 mg/L LM in the second week, and there were no significant differences between the control plants and plants treated with 10, 20, 30, 50, or 60 mg/L LM. In the sixth week, the plant height in response to the 40 mg/L and 50 mg/L LM treatments was significantly greater than that in the control, with increases of 53.64 and 39.80%, respectively. In contrast, plant height in the treatment with 10 mg/L LM decreased slightly (8.53%), but the difference was not significant compared to that in the control. By the eighth week, plant height significantly improved in the 30–60 mg/L LM treatment group, with increases of 25.16, 73.13, 42.34, and 22.47%, respectively, compared to those in the control group. The heights of the plants treated with 10 and 20 mg/L LM did not differ from that of the control plants. The results indicate that the greatest increase in the height of C. indicum was observed in response to the 40 mg/L LM treatment.

The number of roots of C. indicum treated with LM throughout cultivation was not significantly different from that of the untreated plants at every week of cultivation, as shown in Table 2. The leaf number of plants treated with 40 and 50 mg/L LM was significantly greater than that of the control (22.22 and 33.33% increase, respectively) in the second week. No significant differences were detected between the control plants and plants treated with 10, 20, 30, or 60 mg/L LM. An insignificant difference was observed between the untreated and treated groups in the fourth week. In the sixth week, the number of plants treated with 50 mg/L LM was significantly greater than that in the control group (31.25% increase). There were no significant differences between the control and the other conditions. In the final week of cultivation, the leaf number of plants treated with 40–60 mg/L LM was significantly greater than that of untreated plants, with increases of 29.82, 24.56, and 21.05%, respectively. However, no significant difference was detected between the control plants and plants treated with 10, 20, or 30 mg/L LM.

In the second week, the number of nodes did not significantly differ between the untreated and treated groups. In the fourth week, the node number of plants treated with 40 and 60 mg/L LM was significantly greater than that of the control (increases of 22.73 and 13.64%, respectively), whereas there were no significant differences between untreated plants and those treated with 10, 20, 30, or 50 mg/L LM. In the sixth and eighth weeks, the node number of plants exposed to 40 mg/L LM was greater than that of the control plants, with increases of 23.46 and 31.77%, respectively. No significant differences were detected between the control group and the other LM treatment groups. In addition, Fig. 3 shows the agronomy of the plants grown with different concentrations of LM during the eighth week of cultivation. Compared with that in the control treatment, the plant height in the LM treatment group improved.

Table 3 shows the impact of LM on the root length, fresh shoot weight, root fresh weight, shoot dry fresh weight, and root dry weight of C. indicum cuttings in vitro after the eighth week of cultivation. The root length ranged from 17.12 to 25.55 mm, with the control group having a significantly greater root length than that in the treated groups. The lengths of the roots of plants treated with 10–60 mg/L LM decreased significantly, by 17.70, 24.98, 18.21, 21.09, 13.37, and 35.53%, respectively.

The shoot fresh weight varied from 0.143 to 0.335 g and increased in response to the LM treatments, with the maximum shoot weight recorded at 50 mg/L (increased by 101.10%), followed by 40 mg/L (increased by 99.00%) and 60 mg/L (increased by 70.00%). In contrast, a decrease in shoot fresh weight was observed after applying 10 mg/L LM, decreasing by 14.37% compared to that of the control, but no significant difference was found.

The root fresh weight varied from 0.083 to 0.252 g (Table 3). The fresh weight of the roots also increased in the LM treatment group. The maximum value of root fresh weight was recorded after plants were subjected to 50 mg/L LM treatment (an increase of 101.33%), followed by 40 mg/L LM treatment (an increase of 84.00%) and 60 mg/L LM treatment (an increase of 49.33%). Nevertheless, plants treated with 10 and 30 mg/L LM exhibited decreases in root fresh weight of 33.60% and 18.40%, respectively.

The shoot dry weight ranged from 0.0121 to 0.0317 g (Table 3). The maximum shoot dry weight was observed in the 40 mg/L LM treatment group (85.27%), followed by the 50 mg/L LM treatment (58.54%) and the 60 mg/L LM treatment (47.80%) groups. A negative effect on shoot dry weight was recorded in the 10 and 20 mg/L LM treatments, which decreased by 29.24 and 9.36%, respectively, compared with that in the control. A significant difference was found in the 10 mg/LM treatment group, but no significant differences were observed in the 20 mg/L LM treatment group compared to the control group.

The root dry weight ranged from 0.0055 to 0.0191 g (Table 3). The root dry weight significantly increased with the addition of 30–60 mg/L LM. Notably, the maximum root dry weight was recorded in the 40 mg/L LM treatment (increased by 202.11%), followed by the 50 mg/L LM treatment (increased by 136.05%) and the 30 mg/L LM treatment (increased by 184.21%). There were significant differences between the control and plants treated with 10 and 20 mg/L LM. However, a decrease in root dry weight was found in plants treated with 10 mg/L LM (a decrease of 12.30%) compared to the control.

Chlorophyll and total carotenoid contents

The results showed that different concentrations of LM significantly impacted the Chl a, Chl b, total chlorophyll, and total carotenoid contents (Table 4). The results showed that the content of Chl a in the plants treated with 30–60 mg/L LM was significantly greater than that in the control plants, increasing by 37.50, 47.12, 42.31, and 20.19%, respectively. No significant difference was detected between untreated plants and plants treated with 10 or 20 mg/L LM.

Plants treated with all LM concentrations exhibited greater Chl b contents than did the control plants. The highest Chl b content was detected in the 40 mg/L LM-treated plants (an increase of 81.97%), followed by 60 mg/L LM-treated plants (an increase of 36.07%) and 50 mg/L LM-treated plants (an increase of 32.79%). The Chl b content of plants treated with 20 mg/L LM did not significantly differ from that of the control group.

Compared with those of the control plants, the total chlorophyll content of the plants under all LM conditions significantly increased. The maximum total chlorophyll content was recorded in the 40 mg/L LM treatment (60.00%), followed by the 50 mg/L LM treatment (38.79%) and the 30 mg/L LM treatment (32.12%).

The total carotenoid content ranged from 0.26 to 0.31 mg/g DW, as shown in Table 4. The 30 and 50 mg/L LM treatments had the greatest total carotenoid content (0.31 mg/L), followed by the 40 mg/L LM treatment, while an insignificant difference was found between the control plants and those treated with 10 and 20 LM.

Lipid peroxidation and enzyme activities

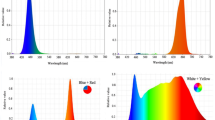

The changes in lipid peroxidation and enzyme activities in plant leaves after LM treatment are depicted in Fig. 4. The MDA level in the plants ranged from 15.30 to 19.25 nM/g FW (Fig. 4a). Compared with the control treatment, the 20–40 mg/L LM treatment reduced the MDA content, while the 10 and 60 mg/L LM treatments had no significant effect on the MDA content. The 40 mg/L LM treatment had the lowest MDA content (a reduction of 19.58%), followed by the 50 mg/L LM treatment (a reduction of 10.04%).

Contents of (a) malondialdehyde (MDA), (b) superoxide dismutase (SOD), (c) ascorbate peroxidase (APX), and (d) catalase (CAT) in C. indicum under six LM conditions (10, 20, 30, 40, 50, and 60 mg/L) after eight weeks of cultivation. CK represents the control group. The results are expressed as the mean ± standard error bar (n = 3). Significantly different values (p < 0.05) are indicated by different letters.

SOD activity in C. indicum markedly increased in all LM treatments, increasing by 6.25–30%, as shown in Fig. 4b. The 40 mg/L LM treatment had the highest SOD activity (an increase of 30%), followed by the 30 (an increase of 18.13%) and 50 mg/L (an increase of 18.13%) leucoxene treatments. The SOD activity of plants treated with 10 mg/L LM did not significantly differ from that of the control group.

APX activity in plants treated with 30–50 mg/L LM was significantly greater than that in the control (Fig. 4c). The maximum level of APX activity was found in response to the 40 mg/L LM treatment, followed by 50 and 30 mg/L LM treatments, which was approximately 133.91, 73.91, and 56.52% compared to the control, respectively. There were no significant differences between control plants and plants treated with 10, 20, or 60 mg/L LM.

Similarly, the activity of CAT in C. indicum treated with LM was greater than that in the control (Fig. 4d). The maximum CAT activity was found in response to the 60 mg/L LM treatment (an increase of approximately threefold), followed by the 40 and 30 mg/L LM treatments (an increase of approximately 2.5-fold). No significant difference was detected between untreated plants and plants treated with 10 or 60 mg/L LM.

Bioactive compounds

The total phenolic content (TPC) and total flavonoid content (TFC) of treated and control C. indicum are summarized in Fig. 5. The TPC of C. indicum treated with LM varied from 2.09 to 3.45 mg GAE/g extract, while the control contained 2.19 mg GAE/g extract (Fig. 5a). The TPC showed positive changes when 30–50 mg/L LM was applied. The maximum TPC occurred at 40 mg/L LM treatment (an increase of 57.65%), followed by 50 mg/L LM treatment (an increase of 57.28%) and 30 mg/L LM treatment (an increase of 30.20%). However, nonsignificant differences between the control and 10 and 60 mg/L LM treatment were observed.

(a) Total phenolic content (TPC) and (b) total flavonoid content (TFC) in C. indicum treated with LM at six concentrations (10, 20, 30, 40, 50, and 60 mg/L) after 8 weeks of cultivation. CK represents the control group. The results are expressed as the mean ± standard error bar (n = 3). Significantly different values (p < 0.05) are indicated by different letters.

The TFC of C. indicum treated with LM ranged from 10.59 to 18.73 mg QUE/g extract, while that of the control was 11.95 mg QUE/g extract, as depicted in Fig. 5b. The LM treatments (30–60 mg/L) significantly improved the TFC (Fig. 5b). The 40 mg/L LM treatment had the greatest increase in TFC (57.23%), followed by the 50 mg/L (32.14%) and 30 mg/L LM (18.40%) treatments. Conversely, a significant reduction in TFC of approximately 10% was observed in the 10 mg/L LM treatment compared to the control.

Antioxidant activity

The change in the DPPH free radical scavenging capacity of C. indicum grown under LM treatment and the untreated control is shown in Fig. 6. The DPPH scavenging activity in C. indicum grown with LM (20–50 mg/L) was greater than that in the untreated group. The highest DPPH scavenging activity was obtained in the 40 mg/g LM treatment group (an increase of 56.97%), followed by the 30 mg/L LM treatment (an increase of 29.19%) and the 20 and 50 mg/L LM treatments (increases of 41.39 and 43.34%, respectively) groups. However, a significant reduction in DPPH scavenging activity, by 10.43 and 13.46%, was observed in the 10 and 60 mg/L LM treatments, respectively, compared to the control. In addition, the coefficient of variation (CV) analysis of all results is shown in the Supplementary file.

Antioxidant activity (DPPH scavenging activity) in C. indicum treated with LM at six concentrations (10, 20, 30, 40, 50, and 60 mg/L) after 8 weeks of cultivation. The results are expressed as the mean ± standard error bar (n = 3). CK represents the control group. Significantly different values (p < 0.05) are indicated by different letters.

Minimum inhibitory concentration (MIC) and minimum bactericidal concentration (MBC) of C. indicum

Table 5 displays the MIC and MBC values of the C. indicum extract against the three bacterial pathogens. The aqueous leaf extract of C. indicum grown under LM conditions and the control had the MIC, < 3.125 mg/mL, against Candida albicans, with a MBC < 3.125 mg/mL. The MIC and MBC values for Staphylococcus aureus and Escherichia coli were < 3.125 mg/mL for C. indicum grown under the 40 and 50 mg/L LM treatments. In addition, the 30 mg/L treatment effectively inhibited Staphylococcus aureus, with MIC and MBC values (< 3.125 mg/mL). These results indicate that plants grown with different concentrations of LM significantly inhibited the growth of bacterial pathogens.

Discussion

In this investigation, a low-cost natural LM was applied to C. indicum to understand its effects on medicinal plants. The chemical composition of the natural LM revealed by EDS indicated that the natural LM was composed of ~ 86% TiO2. The XRD results identified the main phase of anatase and rutile TiO2 with band gaps of 3.2 and 3.0 eV, respectively. The mixed-phase crystallinity of both phases significantly reduces the recombination of electron–hole pairs. According to Nosaka et al.37, photoelectrons preferentially excite the conduction band of rutile because anatase has a lower valence edge than rutile. Holes generated from rutile can quickly pass to the anatase phase and are associated with ROS production. These processes could reduce the recombination of electron–hole pairs37. Consequently, additional ROS can be produced.

According to our results, we found that LM improved the physiological and biochemical parameters of C. indicum plants. The positive impacts on C. indicum growth (especially on plant height, shoot fresh and dry weights, and root fresh and dry weights) were significant in response to the LM treatments at concentrations ranging from 30–50 mg/L, as depicted in Tables 2 and 3. A previous study showed that 100–200 mg/L TiO2 enhanced the growth of tomato and onion plants (shoot and root lengths and shoot fresh and dry weights)38. Similarly, 50–100 mg/L TiO2 improved the leaf number, leaf fresh weight, and dry weight of D. moldavica21. In addition, improvements in plant growth parameters were observed after FeO, SiO2, and Al2O3 exposure39.

The increase in plant growth might be correlated with the increase in photosynthesis, as indicated by the increase in chlorophyll and carotenoid contents. An increase in chlorophyll and carotenoid contents is conducive to improving photosynthesis efficiency, enhancing the synthesis of carbohydrates and increasing the fresh and dry weights of plants23. ROS play dual roles in chloroplast function. First, they are a byproduct of the photosynthetic electron transport chain, and their accumulation can cause oxidative damage to various components of the chloroplast, including chlorophyll and carotenoids40,41. However, moderate levels of ROS have been shown to stimulate chlorophyll biosynthesis and enhance chloroplast development. Various studies have also demonstrated that ROS act as signaling molecules in regulating chlorophyll biosynthesis. In particular, singlet oxygen (1O2) has been shown to stimulate the expression of genes involved in chlorophyll biosynthesis and promote chlorophyll accumulation in the chloroplast40. This effect is thought to be mediated by the activation of transcription factors regulating chlorophyll biosynthesis-related gene expression40. A previous study reported that TiO2 promoted chlorophyll and carotenoid contents in radish23, peppermint42, and maize43. Furthermore, the growth factors of D. moldavica plants treated with 100 mg/L TiO2 improved with increasing levels of Chl a, Chl b, and total carotenoids. On the other hand, a higher concentration of TiO2 could damage plant growth and photosynthetic pigments20,21. In the present study, compared with the 50 mg/L LM treatment, the 60 mg/L LM treatment gradually reduced plant growth. Despite this reduction, the plant growth parameters were not below those of the control, and there was no toxicity in plants treated with LM. In addition, other metal oxides, i.e., FeO, SiO2, and Al2O3, enhance chlorophyll and carotenoid contents in plants44.

ROS are generally generated in chloroplasts via intricate and diverse defense systems that enable photosynthesis to operate efficiently even under challenging environmental conditions with limited resources45. ROS can participate in oxidative signaling and environmental sensing, which extends their functions associated with regulating photosynthesis. Therefore, ROS accumulation involves many critical plant processes, such as cell-to-cell communication and the control of growth and stress responses46,47. However, the overproduction of ROS acts as a signal and plays a key role in oxidative stress, resulting in damage to the cellular components of plants and programmed cell death48. Thus, chloroplasts remove excess ROS to prevent oxidative damage in plants49 and extend the photosynthetic time of chloroplasts by promoting the activity of antioxidant enzymes, i.e., SOD, CAT, and APX50. SOD plays a key role in providing defense against oxidative stress51 by activating the dismutation of superoxide radicals (\({\text{O}}_{2}^{\cdot - }\)) into hydrogen peroxide (H2O2) and oxygen (O2). CAT activity is an essential antioxidant enzyme for the conversion of H2O2 into water and oxygen. APX is another important enzyme that scavenges H2O2 to protect chloroplasts and other cells from H2O2 damage. Therefore, improving antioxidant enzyme activity is strongly associated with high defense against oxidative stress. Notably, enzymatic antioxidants are activated by the formation of ROS during oxidative stress in plants52. Our findings demonstrated that LM enhances antioxidant enzyme activities and contributes to effective C. indicum defense against oxidative stress. In this context, concentrations of LM (30–50 mg/L) promoted increased activity of enzymatic antioxidants (SOD, CAT, and APX), which coincided with reduced levels of MDA, a marker of oxidative damage (Fig. 4). Thus, biochemical profiling of C. indicum revealed that, compared with those in the control plants, ROS accumulation can stimulate the antioxidant machinery, increase the synthesis of phytohormones, and cause minor oxidative damage in plants grown under LM. Similar to our investigations, increasing enzymatic antioxidants were associated with decreased MDA contents in broad bean plants treated with TiO220. Moreover, TiO2 enhanced the growth parameters of D. moldavica plants by increasing enzyme activity and decreasing the MDA content21. Previous evidence has shown the reasonable induction of enzymatic antioxidants after treatment with TiO2, thus reducing plant damage related to ROS accumulation53. SOD, APX, and CAT activities in plants treated with TiO2 have been shown to increase21,54. In addition, promoting APX, CAT, glutathione peroxidase (GPX), and SOD activities in spinach plants treated with TiO2 can alleviate oxidative damage55. A moderate level of TiO2 in Hyoscyamus niger L. plants increased the CAT, GPX, and APX activities56.

Phenolic compounds are a significant group of secondary metabolites in plants that contain at least one aromatic ring bearing one or more hydroxyl groups in their structure. The main structures of these compounds are characterized into three groups: flavonoids, nonflavonoids, and phenolic acids57,58. Phenolic compounds exhibit several plant activities, such as scavenging free radicals, providing protection against ultraviolet (UV), biotic or abiotic stress, and combating pathogenic bacteria. An increase in phenolic compounds scavenges ROS and prevents plant damage. In the present study, the 30–50 LM treatments had higher levels of phenolic compounds in the C. indicum extract than in the control extract (Fig. 5). These results are consistent with those of TiO2 NP exposure in wheat plants infected with Puccinia striiformis, which led to changes in the TPC and TFC of the plants59. Similar findings demonstrated that the TPC and TFC in Dracocephalum kotschyi were improved by TiO2 NPs and exposure time54. Thus, our results show that the TPC and TFC of C. indicum improved in response to LM treatment. In addition, the content of phenolic compounds in plants may increase in response to other stress conditions, i.e., high temperature and UV light. The phenolic compounds of C. indicum depend on various factors, i.e., vegetative propagation, cultivation conditions, and soil type60.

The current investigation demonstrated that the antioxidant capacity of C. indicum extract can be optimized and improved by using low-cost LM. The significant change in antioxidants in C. indicum may be due to its high phenolic compound content. Thus, Pearson’s correlation was performed to determine the relationships between TPC, TFC, and DPPH radical scavenging activity. The experimental evidence showed that DPPH had a strong linear correlation (R = 0.955) with the TPC and a strong correlation (R = 0.740) with the TFC. The results of this study could imply that DPPH in C. indicum is a function of phenolic compounds, especially TPC and TFC. This study is similar to previous findings that revealed a strong correlation between DPPH radical scavenging activity and the TPC and TFC in mushrooms33,61.

The antibacterial properties of aqueous leaf extracts of C. indicum grown under different LM treatment conditions were evaluated. The lowest MIC and MBC were observed for gram-positive bacteria (Staphylococcus aureus), gram-negative bacteria (Escherichia coli), and fungi (Candida albicans) in response to the 40 and 50 mg/L LM treatments, as shown in Table 5. The highest antibacterial effect is primarily related to phenolic compounds and their correlation with the presence of hydroxyl groups. Indeed, the position and number of these hydroxyl groups in the phenolic ring significantly influence the target bacteria, change the structure of the cell membrane, reduce lipid levels, and suppress bacterial growth62. Various reports have shown that phenolic compounds extracted from different fruits can effectively inhibit Staphylococcus aureus and Escherichia coli63. This study suggested that higher levels of phenolic compounds in C. indicum grown under LM treatments provide optimal conditions for antibacterial activity. In addition, the key constituents of C. indium essential oils, in addition to phenolic compounds such as borneol, camphor, p-cymene, and camphene, can also inhibit bacterial growth5.

Conclusion

In the present study, the effect of Thai LM on the growth of C. indicum cuttings in vitro was evaluated. The LM in this study has a rutile and anatase structure, with a granular shape and grain size of 1–40 µm and a chemical composition of ~ 86% TiO2. The LM treatments resulted in greater increases in growth parameters, including plant height, root number, bud number, and fresh and dry weight. LM treatments also increased the chlorophyll and carotenoid contents and antioxidant enzyme activities while decreasing the MDA content, which supported plant growth. The increased phenolic compound content in plants treated with LM has implications for antibacterial applications. The best condition for inhibiting the activity of Staphylococcus aureus, Escherichia coli, and Candida albicans was LM at a concentration of 40–50 mg/L, which yielded the lowest MIC and MBC values. In conclusion, LM with 86% TiO2 is a sustainable and cost-effective method for improving Chrysanthemum growth-promoting molecules and antibacterial activity, leading to the production of innovative, high-quality Chrysanthemum plants.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Choi, H. S. & Kim, G. H. Volatile flavor composition of Gamguk (Chrysanthemum indicum) flower essential oils. Food Sci. Biotechnol. 20, 319–325. https://doi.org/10.1007/s10068-011-0045-2 (2011).

Eisa, E. A., Tilly-Mándy, A., Honfi, P., Shala, A. Y. & Gururani, M. A. Chrysanthemum: A comprehensive review on recent developments on in vitro regeneration. Biology https://doi.org/10.3390/biology11121774 (2022).

Teixeira Da Silva, J. A. Ornamental chrysanthemums: Improvement by biotechnology. Plant Cell Tissue Organ Cult. 79, 1–18. https://doi.org/10.1023/B:TICU.0000049444.67329.b9 (2004).

Cheng, W., Li, J., You, T. & Hu, C. Anti-inflammatory and immunomodulatory activities of the extracts from the inflorescence of Chrysanthemum indicum Linné. J. Ethnopharmacol. 101, 334–337. https://doi.org/10.1016/j.jep.2005.04.035 (2005).

Youssef, F. S. et al. Chrysanthemum indicum and Chrysanthemum morifolium: Chemical composition of their essential oils and their potential use as natural preservatives with antimicrobial and antioxidant activities. Foods https://doi.org/10.3390/foods9101460 (2020).

Somashekar, B. S. & Sharma, M. Propagation Techniques of Commercially Important Medicinal Plants. 118 (FRLHT, 2002).

Panigrahi, J., Dholu, P., Shah, T. J. & Gantait, S. Silver nitrate-induced in vitro shoot multiplication and precocious flowering in Catharanthus roseus (L.) G. Don, a rich source of terpenoid indole alkaloids. Plant Cell Tissue Organ Cult. 132, 579–584. https://doi.org/10.1007/s11240-017-1351-z (2018).

Panigrahi, J., Gantait, S. & Patel, I. C. Concurrent production and relative quantification of vasicinone from in vivo and in vitro plant parts of Malabar nut (Adhatoda vasica Nees). 3 Biotech https://doi.org/10.1007/s13205-017-0882-7 (2017).

Gantait, S. & Mitra, M. Application of in vitro technologies for production of vasicine and vasicinone: Key bioactive compounds of Adhatoda spp.. J. Plant-Deriv. Bioact. Product. Proper. Ther. Appl. https://doi.org/10.1007/978-981-15-1761-7_4 (2020).

Henrique, A., Campinhos, E. N., Ono, E. O. & De Pinho, S. Z. Effect of plant growth regulators in the rooting of Pinus cuttings. Braz. Arch. Biol. Technol. 49, 189–196. https://doi.org/10.1590/S1516-89132006000300002 (2006).

Miler, N., Jedrzejczyk, I., Jakubowski, S. & Winiecki, J. Ovaries of chrysanthemum irradiated with high-energy photons and high-energy electrons can regenerate plants with novel traits. Agronomy https://doi.org/10.3390/agronomy11061111 (2021).

Kim, S. H. et al. Sucrose and methyl jasmonate modulate the expression of anthocyanin biosynthesis genes and increase the frequency of flower-color mutants in chrysanthemum. Sci. Horticult. https://doi.org/10.1016/j.scienta.2019.108602 (2019).

Deein, W., Thepsithar, C. & Thongpukdee, A. In vitro culture medium sterilization by chemicals and essential oils without autoclaving and growth of chrysanthemum nodes. World Acad. Sci. Eng. Technol. Int. J. Biol. Biomol. Agric. Food Biotechnol. Eng. 7, 407–410 (2013).

Pant, M., Lal, A. & Jain, R. A simple cost effective method for mass propagation of Chrysanthemum morifolium and antibacterial activity assessment of in vitro raised plantlets. J. Appl. Pharmaceut. Sci. 5, 103–111. https://doi.org/10.7324/JAPS.2015.50716 (2015).

Alsoufi, A. S. M., Ahmed, Z. S. & Salim, A. M. The efficiency of interaction between cytokines and auxins in micropropagation of Chrysanthemum plant (Chrysanthemum indicum L.). IOP Conf. Ser. Earth Environ. Sci. 735, 012048. https://doi.org/10.1088/1755-1315/735/1/012048 (2021).

Ali, N. S., Kalash, K. R., Ahmed, A. N. & Albayati, T. M. Performance of a solar photocatalysis reactor as pretreatment for wastewater via UV, UV/TiO2, and UV/H2O2 to control membrane fouling. Sci. Rep. https://doi.org/10.1038/s41598-022-20984-0 (2022).

Shabib Akhtar, M. et al. Nanoengineered chitosan functionalized titanium dioxide biohybrids for bacterial infections and cancer therapy. Sci. Rep. 14, 3705. https://doi.org/10.1038/s41598-024-52847-1 (2024).

Ioannou, A. et al. Advanced nanomaterials in agriculture under a changing climate: The way to the future?. Environ. Exp. Bot. https://doi.org/10.1016/j.envexpbot.2020.104048 (2020).

Abdel Latef, A. A. H., Srivastava, A. K., El-sadek, M. S. A., Kordrostami, M. & Tran, L. S. P. Titanium dioxide nanoparticles improve growth and enhance tolerance of broad bean plants under saline soil conditions. Land Degrad. Dev. 29, 1065–1073. https://doi.org/10.1002/ldr.2780 (2018).

Gohari, G. et al. Titanium dioxide nanoparticles (TiO2 NPs) promote growth and ameliorate salinity stress effects on essential oil profile and biochemical attributes of Dracocephalum moldavica. Sci. Rep. https://doi.org/10.1038/s41598-020-57794-1 (2020).

Mustafa, N. et al. Exogenous application of green titanium dioxide nanoparticles (TiO2 NPs) to improve the germination, physiochemical, and yield parameters of wheat plants under salinity stress. Molecules https://doi.org/10.3390/molecules27154884 (2022).

Vatankhah, A. et al. Plants exposed to titanium dioxide nanoparticles acquired contrasting photosynthetic and morphological strategies depending on the growing light intensity: A case study in radish. Sci. Rep. https://doi.org/10.1038/s41598-023-32466-y (2023).

Pavasupree, S. et al. Titanium dioxide nanoparticles affect growth and antibacterial activity of Chrysanthemum indicum cuttings in vitro culture. S. Afr. J. Bot. 156, 72–78. https://doi.org/10.1016/j.sajb.2023.03.005 (2023).

Mohammadi, H. et al. Unraveling the influence of TiO2 nanoparticles on growth, physiological and phytochemical characteristics of Mentha piperita L. in cadmium-contaminated soil. Sci. Rep. 13, 22280. https://doi.org/10.1038/s41598-023-49666-1 (2023).

Omar, S. A. et al. Impact of titanium oxide nanoparticles on growth, pigment content, membrane stability, DNA damage, and stress-related gene expression in Vicia faba under saline conditions. Horticulturae https://doi.org/10.3390/horticulturae9091030 (2023).

Alavi, S. M., Kamali, M., Selahvarzi, Y. & Ansari, S. Deficit irrigation strategies (PRD, SDI) and titanium nanoparticles improve water use efficiency and flower quality in greenhouse-grown cut roses. Sci. Rep. 13, 18019. https://doi.org/10.1038/s41598-023-45042-1 (2023).

Mahmoud, N. E. & Abdelhameed, R. M. Use of titanium dioxide doped multi-wall carbon nanotubes as promoter for the growth, biochemical indices of Sesamum indicum L. under heat stress conditions. Plant Physiol. Biochem. https://doi.org/10.1016/j.plaphy.2023.107844 (2023).

Charerntanom, W., Pecharapa, W., Pavasupree, S. & Pavasupree, S. Effect of calcination temperature on structure and photocatalytic activity under UV and visible light of nanosheets from low-cost magnetic leucoxene mineral. Photon. Nanostruct. Fundam. Appl. 25, 38–45. https://doi.org/10.1016/j.photonics.2017.04.007 (2017).

Phoohinkong, W. et al. Electrochemical properties of nanopowders derived from ilmenite and leucoxene natural minerals. Ceram. Int. 43, S717–S722. https://doi.org/10.1016/j.ceramint.2017.05.275 (2017).

Murashige, T. & Skoog, F. A revised medium for rapid growth and bio assays with tobacco tissue cultures. Physiol. Plant. 15, 473–497. https://doi.org/10.1111/j.1399-3054.1962.tb08052.x (1962).

Wellburn, A. R. The spectral determination of chlorophylls a and b, as well as total carotenoids, using various solvents with spectrophotometers of different resolution. J. Plant Physiol. 144, 307–313. https://doi.org/10.1016/S0176-1617(11)81192-2 (1994).

Raliya, R., Nair, R., Chavalmane, S., Wang, W. N. & Biswas, P. Mechanistic evaluation of translocation and physiological impact of titanium dioxide and zinc oxide nanoparticles on the tomato (Solanum lycopersicum L.) plant. Metallomics 7, 1584–1594. https://doi.org/10.1039/c5mt00168d (2015).

Seelarat, W. et al. Enhanced fruiting body production and bioactive phytochemicals from white Cordyceps militaris by blending Cordyceps militaris and using cold plasma Jet. Plasma Chem. Plasma Process. 43, 139–162. https://doi.org/10.1007/s11090-022-10292-w (2023).

Maema, L. P., Potgieter, M., Masevhe, N. A. & Samie, A. Antimicrobial activity of selected plants against fungal species isolated from South African AIDS patients and their antigonococcal activity. J. Complem. Integr. Med. https://doi.org/10.1515/jcim-2019-0087 (2020).

Sharma, H. & Karnwal, A. Impact of herbal extracts in biocontroling of four human pathogenic bacteria—An in-vitro study. Res. J. Pharm. Technol. 11, 2895–2900. https://doi.org/10.5958/0974-360X.2018.00533.4 (2018).

Duncan, D. B. Multiple range and multiple F tests. Biometrics 11, 1–42. https://doi.org/10.2307/3001478 (1955).

Nosaka, Y. & Nosaka, A. Y. Reconsideration of intrinsic band alignments within anatase and rutile TiO2. J. Phys. Chem. Lett. 7, 431–434. https://doi.org/10.1021/acs.jpclett.5b02804 (2016).

Haghighi, M. & Teixeira Da Silva, J. A. The effect of N-TiO2 on tomato, onion, and radish seed germination. J. Crop Sci. Biotechnol. 17, 221–227. https://doi.org/10.1007/s12892-014-0056-7 (2014).

Tripathi, D. K. et al. An overview on manufactured nanoparticles in plants: Uptake, translocation, accumulation and phytotoxicity. Plant Physiol. Biochem. 110, 2–12. https://doi.org/10.1016/j.plaphy.2016.07.030 (2017).

Krieger-Liszkay, A. Singlet oxygen production in photosynthesis. J. Exp. Bot. 411, 337–346. https://doi.org/10.3389/fpls.2019.01640 (2019).

Das, K. & Roychoudhury, A. Reactive oxygen species (ROS) and response of antioxidants as ROS-scavengers during environmental stress in plants. Front. Environ. Sci. https://doi.org/10.3389/fenvs.2014.00053 (2014).

Ahmad, B., Shabbir, A., Jaleel, H., Khan, M. M. A. & Sadiq, Y. Efficacy of titanium dioxide nanoparticles in modulating photosynthesis, peltate glandular trichomes and essential oil production and quality in Mentha piperita L.. Curr. Plant Biol. 13, 6–15. https://doi.org/10.1016/j.cpb.2018.04.002 (2018).

Moaveni, I., Farahani, H. A. & Maroufi, K. Investigation of TiO2 nanoparticles affectedon some of enzymes in Calendula (Calendula officinalis L.) under field condition. Adv. Environ. Biol. 15, 2238–2241 (2011).

Landa, P. Positive effects of metallic nanoparticles on plants: Overview of involved mechanisms. Plant Physiol. Biochem. 161, 12–24. https://doi.org/10.1016/j.plaphy.2021.01.039 (2021).

Foyer, C. H. Reactive oxygen species, oxidative signaling and the regulation of photosynthesis. Environ. Exp. Bot. 154, 134–142. https://doi.org/10.1016/j.envexpbot.2018.05.003 (2018).

Huang, H., Ullah, F., Zhou, D. X., Yi, M. & Zhao, Y. Mechanisms of ROS regulation of plant development and stress responses. Front. Plant Sci. https://doi.org/10.3389/fpls.2019.00800 (2019).

de Medeiros, R. L. S., de Paula, R. C., de Souza, J. V. O. & Fernandes, J. P. P. Abiotic stress on seed germination and plant growth of Zeyheria tuberculosa. J. For. Res. 34, 1511–1522. https://doi.org/10.1007/s11676-023-01608-3 (2023).

Sunohara, Y., Nakano, K., Matsuyama, S., Oka, T. & Matsumoto, H. Cuminaldehyde, a cumin seed volatile component, induces growth inhibition, overproduction of reactive oxygen species and cell cycle arrest in onion roots. Sci. Horticult. https://doi.org/10.1016/j.scienta.2021.110493 (2021).

Foyer, C. H. & Hanke, G. ROS production and signalling in chloroplasts: Cornerstones and evolving concepts. Plant J. 111, 642–661. https://doi.org/10.1111/tpj.15856 (2022).

Asada, K. Production and scavenging of reactive oxygen species in chloroplasts and their functions. Plant Physiol. 141, 391–396. https://doi.org/10.1104/pp.106.082040 (2006).

Adhikari, B. et al. Cold plasma seed priming modulates growth, redox homeostasis and stress response by inducing reactive species in tomato (Solanum lycopersicum). Free Radic. Biol. Med. 156, 57–69. https://doi.org/10.1016/j.freeradbiomed.2020.06.003 (2020).

Li, Y. et al. Changes of reactive oxygen species and scavenging enzymes of persimmon fruit treated with CO2 deastringency and the effect of hydroxyl radicals on breakdown of cell wall polysaccharides in vitro. Sci. Horticult. 199, 81–87. https://doi.org/10.1016/j.scienta.2015.12.040 (2016).

Filippou, P., Bouchagier, P., Skotti, E. & Fotopoulos, V. Proline and reactive oxygen/nitrogen species metabolism is involved in the tolerant response of the invasive plant species Ailanthus altissima to drought and salinity. Environ. Exp. Bot. 97, 1–10. https://doi.org/10.1016/j.envexpbot.2013.09.010 (2014).

Nourozi, E., Hosseini, B., Maleki, R. & AbdollahiMandoulakani, B. Inductive effect of titanium dioxide nanoparticles on the anticancer compounds production and expression of rosmarinic acid biosynthesis genes in Dracocephalum kotschyi transformed roots. Plant Physiol. Biochem. 167, 934–945. https://doi.org/10.1016/j.plaphy.2021.09.017 (2021).

Lei, Z. et al. Antioxidant stress is promoted by nano-anatase in spinach chloroplasts under UV-B radiation. Biol. Trace Elem. Res. 121, 69–79. https://doi.org/10.1007/s12011-007-8028-0 (2008).

Ghorbanpour, M., Hatami, M. & Hatami, M. Activating antioxidant enzymes, hyoscyamine and scopolamine biosynthesis of Hyoscyamus niger L. Plants with nano-sized titanium dioxide and bulk application. Acta Agric. Slov. 105, 23–32 https://doi.org/10.14720/aas.2015.105.1.03 (2015).

de Souza, E. L., de Albuquerque, T. M. R., dos Santos, A. S., Massa, N. M. L. & de Brito Alves, J. L. Potential interactions among phenolic compounds and probiotics for mutual boosting of their health-promoting properties and food functionalities—A review. Crit. Rev. Food Sci. Nutr. 59, 1645–1659 https://doi.org/10.1080/10408398.2018.1425285 (2019).

Zhang, H. & Tsao, R. Dietary polyphenols, oxidative stress and antioxidant and anti-inflammatory effects. Curr. Opin. Food Sci. 8, 33–42. https://doi.org/10.1016/j.cofs.2016.02.002 (2016).

Satti, S. H. et al. Plant-based titanium dioxide nanoparticles trigger biochemical and proteome modifications in Triticum aestivum L. under biotic stress of Puccinia striiformis. Molecules https://doi.org/10.3390/molecules27134274 (2022).

Ghimire, B. K., Kim, S. H., Yu, C. Y. & Chung, I. M. Biochemical and physiological changes during early adventitious root formation in Chrysanthemum indicum Linné cuttings. Plants https://doi.org/10.3390/plants11111440 (2022).

Sangwanna, S. et al. Air atmospheric pressure plasma jet to improve fruiting body production and enhance bioactive phytochemicals from mutant Cordyceps militaris (white Cordyceps militaris). Food Bioprocess Technol. 16, 1976–1991. https://doi.org/10.1007/s11947-023-03028-x (2023).

Helal, G. A., Sarhan, M. M., Abu Shahla, A. N. K. & Abou El-Khair, E. K. Effects of Cymbopogon citratus L. essential oil on the growth, lipid content and morphogenesis of Aspergillus niger ML2-strain. J. Basic Microbiol. 46, 456–469 https://doi.org/10.1002/jobm.200510106 (2006).

Lima, M. C. et al. A review of the current evidence of fruit phenolic compounds as potential antimicrobials against pathogenic bacteria. Microb. Pathogen. 130, 259–270. https://doi.org/10.1016/j.micpath.2019.03.025 (2019).

Acknowledgements

This research was supported by The Science, Research and Innovation Promotion Funding (TSRI) (Grant No. FRB650070/0168). This research block grants were managed under Rajamangala University of Technology Thanyaburi (FRB65E06021I.1). The pilot scale apparatus was supported by Fundamental Research Budget Allocation (RFB630004/0168) grant funded by Thailand Science Research and Innovation (TSRI) (Granted No. IRF63A0704A.4)

Author information

Authors and Affiliations

Contributions

Sorapong Pavasupree: Writing original draft and editing, and resources. Nattapong Chanchula: Conceptualization and resources. Narittaya Nunya: Methodology and analysis. Sirinya Kashima: Methodology and analysis. Pariya Na Nakorn: Methodology and analysis. Esther Thongaram: Methodology and analysis. Yayoi Shindo: Methodology and analysis. Atipong Bootchanont: Writing-editing and review. Chakkaphan Wattanawikkam: Writing-editing and review. Russameeruk Noonuruk: Writing-editing and review. Kamonporn Srilopan: Methodology and analysis. Porramain Porjai: Conceptualization, writing original draft and editing, project administration, and fund acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pavasupree, S., Chanchula, N., Nunya, N. et al. Influence of low-cost Thai leucoxene minerals on the growth, bioactive compounds, and antibacterial activities of Chrysanthemum indium L. cuttings in in vitro culture. Sci Rep 14, 9505 (2024). https://doi.org/10.1038/s41598-024-60131-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-60131-5

Keywords

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.