Abstract

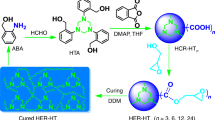

Due to their exceptional manufacturability and excellent mechanical properties, epoxy thermosets are one of the most widely used plastics, finding many industrial applications. However, the crosslinked polymer network renders them inherently brittle and not recyclable, raising sustainability concerns. Here we show epoxy thermosets with combined high toughness and reprocessability by innovating the chemistry of curing, a crosslinking process in polymers. Specifically, taking advantage of a one-pot epoxy curing mechanism with a boronic-ester-containing aromatic diamine crosslinker and an aliphatic monoamine, the stepwise reaction of the amines affords unique nanoscale phase separation. As a result, the epoxy thermoset exhibits maximum elongation of 375% and tensile toughness of 108.4 MJ m−3, more than one order of magnitude higher than that of the conventional counterparts. Moreover, the introduced dynamic boronic ester bonds endow the thermoset with unusual reprocessability for extended service life, while other properties are not compromised notably after four cycles. The feasibility to simultaneously overcome the two major bottlenecks for epoxy thermosets opens opportunities to recycle and reinvent other industrially relevant plastics.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data that support the findings of this study are available as Source data Figs. 1–4 and Supplementary_data_set. They are also available via Figshare (https://doi.org/10.6084/m9.figshare.25425292). Source data are provided with this paper.

References

Jambeck, J. R. et al. Plastic waste inputs from land into the ocean. Science 347, 768–771 (2015).

Garcia, J. M. & Robertson, M. L. The future of plastics recycling. Science 358, 870–872 (2017).

Sardon, H. & Dove, A. P. Plastics recycling with a difference. Science 360, 380–381 (2018).

Ahrens, A. et al. Catalytic disconnection of C–O bonds in epoxy resins and composites. Nature 617, 730–737 (2023).

Lopez de Pariza, X. et al. Recyclable photoresins for light-mediated additive manufacturing towards loop 3D printing. Nat. Commun. 14, 5504 (2023).

Liu, Z. et al. Chemical upcycling of commodity thermoset polyurethane foams towards high-performance 3D photo-printing resins. Nat. Chem. 15, 1773–1779 (2023).

Wang, C. et al. Recyclable and repolymerizable thiol–X photopolymers. Mater. Horiz. 5, 1042–1046 (2018).

Xu, Z. et al. Recyclable thermoset hyperbranched polymers containing reversible hexahydro-s-triazine. Nat. Sustain. 3, 29–34 (2020).

Fortman, D. J. et al. Approaches to sustainable and continually recyclable crosslinked polymers. ACS Sustain. Chem. Eng. 6, 11145–11159 (2018).

Sheppard, D. T. et al. Reprocessing postconsumer polyurethane foam using carbamate exchange catalysis and twin-screw extrusion. ACS Cent. Sci. 6, 921–927 (2020).

Montarnal, D., Capelot, M., Tournilhac, F. & Leibler, L. Silica-like malleable materials from permanent organic networks. Science 334, 965–968 (2011).

Guerre, M., Taplan, C., Winne, J. M. & Du Prez, F. E. Vitrimers: directing chemical reactivity to control material properties. Chem. Sci. 11, 4855–4870 (2020).

Röttger, M. et al. High-performance vitrimers from commodity thermoplastics through dioxaborolane metathesis. Science 356, 62–65 (2017).

He, C., Shi, S., Wang, D., Helms, B. A. & Russell, T. P. Poly(oxime-ester) vitrimers with catalyst-free bond exchange. J. Am. Chem. Soc. 141, 13753–13757 (2019).

Denissen, W. et al. Vinylogous urethane vitrimers. Adv. Funct. Mater. 25, 2451–2457 (2015).

Ogden, W. A. & Guan, Z. Recyclable, strong, and highly malleable thermosets based on boroxine networks. J. Am. Chem. Soc. 140, 6217–6220 (2018).

Zhang, B., Kowsari, K., Serjouei, A., Dunn, M. L. & Ge, Q. Reprocessable thermosets for sustainable three dimensional printing. Nat. Commun. 9, 1831 (2018).

Liu, W. X. et al. Dynamic multiphase semi-crystalline polymers based on thermally reversible pyrazole–urea bonds. Nat. Commun. 10, 4753 (2019).

Taynton, P. et al. Heat- or water-driven malleability in a highly recyclable covalent network polymer. Adv. Mater. 26, 3938–3942 (2014).

Xi, X. et al. Toughness and its mechanisms in epoxy resins. Prog. Mater. Sci. 130, 100977 (2022).

Cao, Q. et al. Engineering double load-sharing network in thermosetting: much more than just toughening. Macromolecules 55, 9502–9512 (2022).

Sharifi, M. & Palmese, G. R. Ductile high-Tg epoxy systems via incorporation of partially reacted substructures. J. Mater. Chem. A 9, 1014–1024 (2021).

Asifa, A., Rao, V. L. & Ninan, K. N. Preparation, characterization, thermo-mechanical, and barrier properties of exfoliated thermoplastic toughened epoxy clay ternary nanocomposites. Polym. Adv. Technol. 22, 437–447 (2011).

Yin, X. et al. Synergistic toughening of epoxy resin by CTBN and CM-β-CD. J. Appl. Polym. 42, 51248 (2021).

Chang, W. et al. Strengthening and toughening epoxy polymer at cryogenic temperature using cupric oxide nanorods. Compos. Sci. Technol. 208, 108762 (2021).

Liu, J. et al. Toughening of epoxies with block copolymer micelles of wormlike morphology. Macromolecules 43, 7238–7243 (2010).

Gao, J., Chu, X., Henry, C. K., Santos, S. C. & Palmese, G. R. Highly ductile glassy epoxy systems obtained by network topology modification using partially reacted substructures. Polymer 212, 123260 (2021).

Sharifi, M., Jang, C. W., Abrams, C. F. & Palmese, G. R. Toughened epoxy polymers via rearrangement of network topology. J. Mater. Chem. A 2, 16071–16082 (2014).

Cooper, C. B. et al. High energy density shape memory polymers using strain-induced supramolecular nanostructures. ACS Cent. Sci. 7, 1657–1667 (2021).

Guo, Z. et al. Engineering of chain rigidity and hydrogen bond cross‐linking toward ultra‐strong, healable, recyclable, and water‐resistant elastomers. Adv. Mater. 35, 2300286 (2023).

Auvergne, R., Caillol, S., David, G., Boutevin, B. & Pascault, J. Biobased thermosetting epoxy: present and future. Chem. Rev. 114, 1082–1115 (2014).

Beaucage, G. Approximations leading to a unified exponential/power-law approach to small-angle scattering. J. Appl. Crystallogr. 28, 717–728 (1995).

Zhang, X., Wang, S., Jiang, Z., Li, Y. & Jing, X. Boronic ester based vitrimers with enhanced stability via internal boron–nitrogen coordination. J. Am. Chem. Soc. 142, 21852–21860 (2020).

Westerman, C. R., McGill, B. C. & Wilker, J. J. Sustainably sourced components to generate high-strength adhesives. Nature 621, 306–311 (2023).

Acknowledgements

This research was supported by the National Natural Science Foundation of China (grant numbers U23A2098 (T.X.), 52322307 (N.Z.), 22275162 (N.Z.) and 22288102 (T.X.)). We thank N. Zheng, L. Xu, H. Li and S. Shen for their assistance in performing SEM and DMA tests at the State Key Laboratory of Chemical Engineering (Zhejiang University) and L. Chen for performing near-infrared analyses at the State Key Laboratory of Extreme Photonics and Instrumentation (Zhejiang University).

Author information

Authors and Affiliations

Contributions

N.Z. and T.X. conceived the idea and supervised the project. W.W. and H.F. conducted the experiments with assistance from L.X. and Z.L. The SAXS data were analysed by A.Z. and F.L. The paper was written by W.W., N.Z. and T.X.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Sustainability thanks Xinli Jing, Jian-Bo Zhu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Materials, SAXS data analysis, Supplementary Tables 1–6, Figs. 1–13 and additional references.

Supplementary Data Set 1

Source data for Supplementary Figs. 1–13, source figures for TEM and SEM.

Source data

Source Data Fig. 1

Statistical source data.

Source Data Fig. 2

Statistical source data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, W., Feng, H., Xie, L. et al. Reprocessable and ultratough epoxy thermosetting plastic. Nat Sustain (2024). https://doi.org/10.1038/s41893-024-01331-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41893-024-01331-9