Abstract

When solutions and slurries are directionally solidified, complex dynamics of solvent crystal growth and solvent templating determine the final hierarchical architecture of the freeze-cast material. With continuous X-ray tomoscopy, it is now possible to study in situ intricate and otherwise elusive ice crystal growth and solvent-templating phenomena. Quantifying these phenomena both time-resolved and in three dimensions provides novel insights into the formation of performance-defining features of freeze-cast cellular solids at several length scales: the material’s pore morphology (first hierarchical level), the molecular, fibrillar and particle self-assembly of components in the cell walls (second level) and the cell wall surface structures (third level). The freeze casting process is attractive because the features of the final hierarchical material architecture — which determine the material’s structural, mechanical and physical properties — can be custom designed for a given application. Overall porosity, pore size, geometry, orientation, particle packing in cell walls and cell wall surface features can be tailored for applications in, for example, biomedicine, environmental engineering, catalysis, power conversion, and energy generation and storage.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 1 digital issues and online access to articles

$99.00 per year

only $99.00 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Deville, S., Saiz, E., Nalla, R. K. & Tomsia, A. P. Freezing as a path to build complex composites. Science 311, 515–518 (2006).

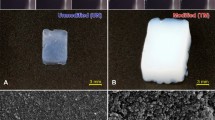

Donius, A. E. et al. Cryogenic EBSD reveals structure of directionally solidified ice–polymer composite. Mater. Charact. 93, 184–190 (2014). The only cryogenic EBSD and SEM study to date reveals crystallographic orientation and morphology of a directionally solidified ice–polymer composite in the as-frozen state.

Schoof, H., Bruns, L., Fischer, A., Heschel, I. & Rau, G. Dendritic ice morphology in unidirectionally solidified collagen suspensions. J. Cryst. Growth 209, 122–129 (2000).

Scotti, K. L. & Dunand, D. C. Freeze casting – a review of processing, microstructure and properties via the open data repository, FreezeCasting.net. Prog. Mater. Sci. 94, 243–305 (2018).

Wegst, U. G. K., Schecter, M., Donius, A. E. & Hunger, P. M. Biomaterials by freeze casting. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 368, 2099–2121 (2010).

Donius, A. E., Liu, A., Berglund, L. A. & Wegst, U. G. K. Superior mechanical performance of highly porous, anisotropic nanocellulose–montmorillonite aerogels prepared by freeze casting. J. Mech. Behav. Biomed. Mater. 37, 88–99 (2014).

Hunger, P. M., Donius, A. E. & Wegst, U. G. K. Structure–property–processing correlations in freeze-cast composite scaffolds. Acta Biomater. 9, 6338–6348 (2013).

Hunger, P. M., Donius, A. E. & Wegst, U. G. K. Platelets self-assemble into porous nacre during freeze casting. J. Mech. Behav. Biomed. Mater. 19, 87–93 (2013). Report of the discovery of interdendritic shear flow as the mechanism for particle self-assembly and structure formation through the observation of ceramic platelets self-assembling into porous nacre during directional solidification.

Araki, K. & Halloran, J. W. Room-temperature freeze casting for ceramics with nonaqueous sublimable vehicles in the naphthalene–camphor eutectic system. J. Am. Ceram. Soc. 87, 2014–2019 (2004).

Cheng, Q., Huang, C. & Tomsia, A. P. Freeze casting for assembling bioinspired structural materials. Adv. Mater. 29, 1703155 (2017).

Chino, Y. & Dunand, D. C. Directionally freeze-cast titanium foam with aligned, elongated pores. Acta Mater. 56, 105–113 (2008).

Fukasawa, T., Deng, Z.-Y., Ando, M., Ohji, T. & Kanzaki, S. Synthesis of porous silicon nitride with unidirectionally aligned channels using freeze-drying process. J. Am. Ceram. Soc. 85, 2151–2155 (2002).

Porter, M. M. et al. Magnetic freeze casting inspired by nature. Mater. Sci. Eng. A 556, 741–750 (2012). To our knowledge, this first report on structural control via an externally applied field, here a magnetic one, inspires the use of other externally applied fields, such as electrical and acoustic, to custom design and control the structure and properties of freeze-cast materials.

Weaver, J. S., Kalidindi, S. R. & Wegst, U. G. K. Structure-processing correlations and mechanical properties in freeze-cast Ti-6Al-4V with highly aligned porosity and a lightweight Ti-6Al-4V-PMMA composite with excellent energy absorption capability. Acta Mater. 132, 182–192 (2017).

Wilke, S. K., Mack, J. B., Kenel, C. & Dunand, D. C. Evolution of directionally freeze-cast Fe2O3 and Fe2O3 + NiO green bodies during reduction and sintering to create lamellar Fe and Fe-20Ni foams. J. Alloy. Compd. 889, 161707 (2021).

Kádár, C. et al. Investigation of the compressive behavior of a freeze-cast Cu foam using acoustic emission measurement. Adv. Eng. Mater. 24, 2100378 (2022).

Picot, O. T. et al. Using graphene networks to build bioinspired self-monitoring ceramics. Nat. Commun. 8, 14425 (2017).

Qiu, K. & Wegst, U. G. K. Excellent specific mechanical and electrical properties of anisotropic freeze-cast native and carbonized bacterial cellulose-alginate foams. Adv. Funct. Mater. 32, 2105635 (2022).

Qiu, L., Liu, J. Z., Chang, S. L. Y., Wu, Y. & Li, D. Biomimetic superelastic graphene-based cellular monoliths. Nat. Commun. 3, 1241 (2012).

Wang, C. et al. Freeze-casting produces a graphene oxide aerogel with a radial and centrosymmetric structure. ACS Nano 12, 5816–5825 (2018).

Yin, K. et al. Hierarchical structure formation by crystal growth-front instabilities during ice templating. Proc. Natl. Acad. Sci. USA 120, e2210242120 (2023). The fundamental science of ice crystal growth and ice templating is presented with an integrated experimental and phase-field simulation approach.

Lee, E.-J., Koh, Y.-H., Yoon, B.-H., Kim, H.-E. & Kim, H.-W. Highly porous hydroxyapatite bioceramics with interconnected pore channels using camphene-based freeze casting. Mater. Lett. 61, 2270–2273 (2007).

Naviroj, M., Voorhees, P. W. & Faber, K. T. Suspension- and solution-based freeze casting for porous ceramics. J. Mater. Res. 32, 3372–3382 (2017).

Chen, R., Wang, C.-A., Huang, Y., Ma, L. & Lin, W. Ceramics with special porous structures fabricated by freeze-gelcasting: using tert-butyl alcohol as a template. J. Am. Ceram. Soc. 90, 3478–3484 (2007).

Naviroj, M., Miller, S. M., Colombo, P. & Faber, K. T. Directionally aligned macroporous SiOC via freeze casting of preceramic polymers. J. Eur. Ceram. Soc. 35, 2225–2232 (2015).

Cui, Y., Gong, H., Wang, Y., Li, D. & Bai, H. A thermally insulating textile inspired by polar bear hair. Adv. Mater. 30, 1706807 (2018). Introduces continuous freeze casting, in this case freeze spinning, for the manufacture of continuous fibres with a controlled and aligned pore architecture.

Zhang, Q. et al. 3D printing of graphene aerogels. Small 12, 1702–1708 (2016).

Caruso, I., Yin, K., Divakar, P. & Wegst, U. G. K. Tensile properties of freeze-cast collagen scaffolds: how processing conditions affect structure and performance in the dry and fully hydrated states. J. Mech. Behav. Biomed. Mater. 144, 105897 (2023).

Divakar, P., Yin, K. & Wegst, U. G. K. Anisotropic freeze-cast collagen scaffolds for tissue regeneration: how processing conditions affect structure and properties in the dry and fully hydrated states. J. Mech. Behav. Biomed. Mater. 90, 350–364 (2019).

Divakar, P., Yin, K. & Wegst, U. G. K. Values and property charts for anisotropic freeze-cast collagen scaffolds for tissue regeneration. Data Brief. 22, 502–507 (2019).

Yin, K., Divakar, P. & Wegst, U. G. K. Plant-derived nanocellulose as structural and mechanical reinforcement of freeze-cast chitosan scaffolds for biomedical applications. Biomacromolecules 20, 3733–3745 (2019).

Yin, K., Divakar, P. & Wegst, U. G. K. Freeze-casting porous chitosan ureteral stents for improved drainage. Acta Biomater. 84, 231–241 (2019).

Yin, K., Divakar, P. & Wegst, U. G. K. Structure-property-processing correlations of longitudinal freeze-cast chitosan scaffolds for biomedical applications. J. Mech. Behav. Biomed. Mater. 121, 104589 (2021).

Kamm, P. H. et al. X-ray tomoscopy reveals the dynamics of ice templating. Adv. Funct. Mater. 33, 2304738 (2023). Introduces X-ray tomoscopy as currently the only technique to image and quantify in three dimensions with high spatial and temporal resolution the dynamics of ice crystal growth, instability formation and ice templating of the hierarchical architecture typical of freeze-cast materials.

García-Moreno, F. et al. Using X-ray tomoscopy to explore the dynamics of foaming metal. Nat. Commun. 10, 3762 (2019).

García-Moreno, F. et al. Tomoscopy: time-resolved tomography for dynamic processes in materials. Adv. Mater. 33, 2104659 (2021). Several applications for X-ray tomoscopy are presented to illustrate how the dynamics of processes can be visualized and quantified with imaging rates up to 1,000 tps over a period of minutes.

García-Moreno, F., Neu, T. R., Kamm, P. H. & Banhart, J. X-ray tomography and tomoscopy on metals: a review. Adv. Eng. Mater. 25, 2201355 (2023).

Betz, O. et al. Imaging applications of synchrotron X-ray phase-contrast microtomography in biological morphology and biomaterials science. I. General aspects of the technique and its advantages in the analysis of millimetre-sized arthropod structure. J. Microsc. 227, 51–71 (2007).

Withers, P. J. et al. X-ray computed tomography. Nat. Rev. Methods Primer 1, 17 (2021).

Yashiro, W., Voegeli, W. & Kudo, H. Exploring frontiers of 4D X-ray tomography. Appl. Sci. 11, 8868 (2021).

Deville, S., Adrien, J., Maire, E., Scheel, M. & Di Michiel, M. Time-lapse, three-dimensional in situ imaging of ice crystal growth in a colloidal silica suspension. Acta Mater. 61, 2077–2086 (2013).

Deville, S. et al. In situ X-ray radiography and tomography observations of the solidification of aqueous alumina particle suspensions. Part I: initial instants. J. Am. Ceram. Soc. 92, 2489–2496 (2009).

Deville, S. et al. In situ X-ray radiography and tomography observations of the solidification of aqueous alumina particles suspensions. Part II: steady state. J. Am. Ceram. Soc. 92, 2497–2503 (2009).

Kamm, P. H., Neu, T. R., García-Moreno, F. & Banhart, J. Nucleation and growth of gas bubbles in AlSi8Mg4 foam investigated by X-ray tomoscopy. Acta Mater. 206, 116583 (2021).

Maire, E., Le Bourlot, C., Adrien, J., Mortensen, A. & Mokso, R. 20 Hz X-ray tomography during an in situ tensile test. Int. J. Fract. 200, 3–12 (2016).

Maire, E. & Withers, P. J. Quantitative X-ray tomography. Int. Mater. Rev. 59, 1–43 (2014).

Seitzman, N. et al. Operando X-ray tomography imaging of solid-state electrolyte response to Li evolution under realistic operating conditions. ACS Appl. Energy Mater. 4, 1346–1355 (2021).

Tong, H., Noda, I. & Gryte, C. C. CPS 768 formation of anisotropic ice-agar composites by directional freezing. Colloid Polym. Sci. 262, 589–595 (1984). To our knowledge, the first report to correlate temperature gradient, freezing front velocity and lamellar spacing, and the discovery of birefringence in a freeze-cast bulk sample, implying preferential molecular alignment during the directional solidification of an aqueous binary polymer solution.

Deville, S., Saiz, E. & Tomsia, A. P. Freeze casting of hydroxyapatite scaffolds for bone tissue engineering. Biomaterials 27, 5480–5489 (2006).

Lloreda-Jurado, P. J. et al. Structure–processing relationships of freeze-cast iron foams fabricated with various solidification rates and post-casting heat treatment. J. Mater. Res. 35, 2587–2596 (2020).

Waschkies, T., Oberacker, R. & Hoffmann, M. J. Investigation of structure formation during freeze-casting from very slow to very fast solidification velocities. Acta Mater. 59, 5135–5145 (2011).

Waschkies, T., Oberacker, R. & Hoffmann, M. J. Control of lamellae spacing during freeze casting of ceramics using double-side cooling as a novel processing route. J. Am. Ceram. Soc. 92, S79–S84 (2009).

Munch, E., Saiz, E., Tomsia, A. P. & Deville, S. Architectural control of freeze-cast ceramics through additives and templating. J. Am. Ceram. Soc. 92, 1534–1539 (2009).

Naviroj, M., Wang, M. M., Johnson, M. T. & Faber, K. T. Nucleation-controlled freeze casting of preceramic polymers for uniaxial pores in Si-based ceramics. Scr. Mater. 130, 32–36 (2017).

Cline, C. et al. Heterogeneous ice nucleation studied with single-layer graphene. Langmuir 38, 15121–15131 (2022).

Kurz, W. & Fisher, D. J. Fundamentals of Solidification (Trans Tech, 1998).

Deville, S. Freezing Colloids: Observations, Principles, Control, and Use: Applications in Materials Science, Life Science, Earth Science, Food Science, and Engineering (Springer, 2017).

Petrenko, V. F. & Whitworth, R. W. Physics of Ice. (Oxford University Press, 2002).

Tiller, W. A., Jackson, K. A., Rutter, J. W. & Chalmers, B. The redistribution of solute atoms during the solidification of metals. Acta Metall. 1, 428–437 (1953).

Mullins, W. W. & Sekerka, R. F. Stability of a planar interface during solidification of a dilute binary alloy. J. Appl. Phys. 35, 444–451 (1964).

Riblett, B. W., Francis, N. L., Wheatley, M. A. & Wegst, U. G. K. Ice-templated scaffolds with microridged pores direct DRG neurite growth. Adv. Funct. Mater. 22, 4920–4923 (2012).

Heschel, I., Lückge, C., Rödder, M., Garberding, C. & Rau, G. in Kittel, P. Advances in Cryogenic Engineering (ed. Kittel, P.) 13–19 (Springer, 1996).

Arai, N. & Faber, K. T. Gradient-controlled freeze casting of preceramic polymers. J. Eur. Ceram. Soc. 43, 1904–1911 (2023).

Bouville, F. et al. Templated grain growth in macroporous materials. J. Am. Ceram. Soc. 97, 1736–1742 (2014).

Pawelec, K. M., Husmann, A., Best, S. M. & Cameron, R. E. Understanding anisotropy and architecture in ice-templated biopolymer scaffolds. Mater. Sci. Eng. C. 37, 141–147 (2014).

Bai, H., Chen, Y., Delattre, B., Tomsia, A. P. & Ritchie, R. O. Bioinspired large-scale aligned porous materials assembled with dual temperature gradients. Sci. Adv. 1, e1500849 (2015).

Davidenko, N. et al. Biomimetic collagen scaffolds with anisotropic pore architecture. Acta Biomater. 8, 667–676 (2012).

Harley, B. A., Hastings, A. Z., Yannas, I. V. & Sannino, A. Fabricating tubular scaffolds with a radial pore size gradient by a spinning technique. Biomaterials 27, 866–874 (2006).

Su, F. Y., Mok, J. R. & McKittrick, J. Radial-concentric freeze casting inspired by porcupine fish spines. Ceramics 2, 161–179 (2019).

Yin, K., Mylo, M. D., Speck, T. & Wegst, U. G. K. 2D and 3D graphical datasets for bamboo-inspired tubular scaffolds with functional gradients: micrographs and tomograms. Data Brief. 31, 105870 (2020).

Yin, K., Mylo, M. D., Speck, T. & Wegst, U. G. K. Bamboo-inspired tubular scaffolds with functional gradients. J. Mech. Behav. Biomed. Mater. 110, 103826 (2020).

Li, D., Bu, X., Xu, Z., Luo, Y. & Bai, H. Bioinspired multifunctional cellular plastics with a negative poisson’s ratio for high energy dissipation. Adv. Mater. 32, 2001222 (2020).

Tian, L. et al. Tailoring centripetal metamaterial with superelasticity and negative Poisson’s ratio for organic solvents adsorption. Sci. Adv. 8, eabo1014 (2022).

Niksiar, P., Frank, M. B., McKittrick, J. & Porter, M. M. Microstructural evolution of paramagnetic materials by magnetic freeze casting. J. Mater. Res. Technol. 8, 2247–2254 (2019).

Yin, K., Reese, B. A., Sullivan, C. R. & Wegst, U. G. K. Superior mechanical and magnetic performance of highly anisotropic sendust‐flake composites freeze cast in a uniform magnetic field. Adv. Funct. Mater. 31, 2007743 (2020).

Tang, Y., Qiu, S., Miao, Q. & Wu, C. Fabrication of lamellar porous alumina with axisymmetric structure by directional solidification with applied electric and magnetic fields. J. Eur. Ceram. Soc. 36, 1233–1240 (2016).

Tang, Y. F., Zhao, K., Wei, J. Q. & Qin, Y. S. Fabrication of aligned lamellar porous alumina using directional solidification of aqueous slurries with an applied electrostatic field. J. Eur. Ceram. Soc. 30, 1963–1965 (2010).

Ogden, T. A., Prisbrey, M., Nelson, I., Raeymaekers, B. & Naleway, S. E. Ultrasound freeze casting: fabricating bioinspired porous scaffolds through combining freeze casting and ultrasound directed self-assembly. Mater. Des. 164, 107561 (2019).

Porter, M. M. et al. Torsional properties of helix-reinforced composites fabricated by magnetic freeze casting. Compos. Struct. 119, 174–184 (2015).

Moritz, T. & Richter, H.-J. Ice-mould freeze casting of porous ceramic components. J. Eur. Ceram. Soc. 27, 4595–4601 (2007).

Yu, R. et al. Graphene oxide/chitosan aerogel microspheres with honeycomb-cobweb and radially oriented microchannel structures for broad-spectrum and rapid adsorption of water contaminants. ACS Appl. Mater. Interfaces 9, 21809–21819 (2017).

Wu, M. et al. Biomimetic knittable aerogel fiber for thermal insulation textile. Science 382, 1379–1383 (2023).

Shen, H. et al. Scalable freeze-tape-casting fabrication and pore structure analysis of 3D LLZO solid-state electrolytes. ACS Appl. Mater. Interfaces 12, 3494–3501 (2020).

Chen, Y., Bunch, J., Li, T., Mao, Z. & Chen, F. Novel functionally graded acicular electrode for solid oxide cells fabricated by the freeze-tape-casting process. J. Power Sources 213, 93–99 (2012).

Guo, Y., Jiang, Y., Zhang, Q., Wan, D. & Huang, C. Directional LiFePO4 cathode structure by freeze tape casting to improve lithium ion diffusion kinetics. J. Power Sources 506, 230052 (2021).

Hwa, Y. et al. Three-dimensionally aligned sulfur electrodes by directional freeze tape casting. Nano Lett. 19, 4731–4737 (2019).

Parikh, D. & Li, J. Bilayer hybrid graphite anodes via freeze tape casting for extreme fast charging applications. Carbon 196, 525–531 (2022).

Sofie, S. W. Fabrication of functionally graded and aligned porosity in thin ceramic substrates with the novel freeze–tape-casting process. J. Am. Ceram. Soc. 90, 2024–2031 (2007).

Yang, W. et al. Freeze-assisted tape casting of vertically aligned MXene films for high rate performance supercapacitors. Energy Environ. Mater. 3, 380–388 (2020).

Xiong, Z., Yan, Y., Wang, S., Zhang, R. & Zhang, C. Fabrication of porous scaffolds for bone tissue engineering via low-temperature deposition. Scr. Mater. 46, 771–776 (2002).

Song, X. et al. Biomimetic 3D printing of hierarchical and interconnected porous hydroxyapatite structures with high mechanical strength for bone cell culture. Adv. Eng. Mater. 21, 1800678 (2019).

Snyder, J. E. et al. Combined multi-nozzle deposition and freeze casting process to superimpose two porous networks for hierarchical three-dimensional microenvironment. Biofabrication 6, 015007 (2014).

Reed, S. et al. Macro- and micro-designed chitosan-alginate scaffold architecture by three-dimensional printing and directional freezing. Biofabrication 8, 015003 (2016).

Körber, C., Scheiwe, M.-W. & Wollhöver, K. A cryomicroscope for the analysis of solute polarization during freezing. Cryobiology 21, 68–80 (1984).

Körber, C. et al. Low temperature light microscopy and its application to study freezing in aqueous solutions and biological cell suspensions. J. Microsc. 141, 263–276 (1986).

Rubinsky, B. & Ikeda, M. A cryomicroscope using directional solidification for the controlled freezing of biological material. Cryobiology 22, 55–68 (1985).

Dedovets, D., Monteux, C. & Deville, S. Five-dimensional imaging of freezing emulsions with solute effects. Science 360, 303–306 (2018).

Dedovets, D., Monteux, C. & Deville, S. A temperature-controlled stage for laser scanning confocal microscopy and case studies in materials science. Ultramicroscopy 195, 1–11 (2018).

Dedovets, D. & Deville, S. Multiphase imaging of freezing particle suspensions by confocal microscopy. J. Eur. Ceram. Soc. 38, 2687–2693 (2018).

Marcellini, M., Noirjean, C., Dedovets, D., Maria, J. & Deville, S. Time-lapse, in situ imaging of ice crystal growth using confocal microscopy. ACS Omega 1, 1019–1026 (2016).

Körber, C., Rau, G., Cosman, M. D. & Cravalho, E. G. Interaction of particles and a moving ice-liquid interface. J. Cryst. Growth 72, 649–662 (1985).

Lipp, G., Körber, C. & Rau, G. Critical growth rates of advancing ice-water interfaces for particle encapsulation. J. Cryst. Growth 99, 206–210 (1990).

Fabietti, L. M., Seetharaman, V. & Trivedi, R. The development of solidification microstructures in the presence of lateral constraints. Metall. Trans. A 21, 1299–1310 (1990).

Mota, F. L., Fabietti, L. M., Bergeon, N. & Trivedi, R. The effect of confinement on thermal convection and longitudinal macrosegregation in directionally solidified dilute succinonitrile–camphor alloy. Comptes Rendus Mécanique 351 (Suppl. 2), 249–262 (2023).

Hoshino, M., Uesugi, K. & Yagi, N. 4D X-ray phase contrast tomography for repeatable motion of biological samples. Rev. Sci. Instrum. 87, 093705 (2016).

Escauriza, E. M. et al. Ultra-high-speed indirect X-ray imaging system with versatile spatiotemporal sampling capabilities. Appl. Opt. 57, 5004–5010 (2018).

Vagovič, P. et al. Megahertz X-ray microscopy at X-ray free-electron laser and synchrotron sources. Optica 6, 1106–1109 (2019).

Bareggi, A., Maire, E., Lasalle, A. & Deville, S. Dynamics of the freezing front during the solidification of a colloidal alumina aqueous suspension: in situ X-ray radiography, tomography, and modeling. J. Am. Ceram. Soc. 94, 3570–3578 (2011).

Yang, G. et al. In situ imaging of three dimensional freeze printing process using rapid X-ray synchrotron radiography. Rev. Sci. Instrum. 93, 013703 (2022).

Lohse, L. M. et al. A phase-retrieval toolbox for X-ray holography and tomography. J. Synchrotron Radiat. 27, 852–859 (2020).

Paganin, D., Mayo, S. C., Gureyev, T. E., Miller, P. R. & Wilkins, S. W. Simultaneous phase and amplitude extraction from a single defocused image of a homogeneous object. J. Microsc. 206, 33–40 (2002). Introduces a new phase retrieval method based on the use of only one radiographic projection, which signifantly enhances image contrast and data processing speeds in X-ray tomography and tomoscopy.

Weitkamp, T., Haas, D., Wegrzynek, D. & Rack, A. ANKAphase: software for single-distance phase retrieval from inline X-ray phase-contrast radiographs. J. Synchrotron Radiat. 18, 617–629 (2011).

Schneider, C. A., Rasband, W. S. & Eliceiri, K. W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 9, 671–675 (2012).

Schindelin, J. et al. Fiji: an open-source platform for biological-image analysis. Nat. Methods 9, 676–682 (2012).

Tsai, E. H. R., Marone, F. & Guizar-Sicairos, M. Gridrec-MS: an algorithm for multi-slice tomography. Opt. Lett. 44, 2181–2184 (2019).

Arganda-Carreras, I. et al. Trainable Weka segmentation: a machine learning tool for microscopy pixel classification. Bioinformatics 33, 2424–2426 (2017).

Arzt, M. et al. LABKIT: labeling and segmentation toolkit for big image data. Front. Comput. Sci. 4, 777728 (2022).

Ronneberger, O., Fischer, P. & Brox, T. in Medical Image Computing and Computer-Assisted Intervention — MICCAI 2015 (eds. Navab, N., Hornegger, J., Wells, W. M. & Frangi, A. F.) Part III. LNCS 9351, 234–241 (Springer, 2015).

Berg, S. et al. ilastik: interactive machine learning for (bio)image analysis. Nat. Methods 16, 1226–1232 (2019).

Ollion, J., Cochennec, J., Loll, F., Escudé, C. & Boudier, T. TANGO: a generic tool for high-throughput 3D image analysis for studying nuclear organization. Bioinformatics 29, 1840–1841 (2013).

Van Der Walt, S. et al. scikit-image: image processing in Python. PeerJ 2, e453 (2014).

Legland, D., Arganda-Carreras, I. & Andrey, P. MorphoLibJ: integrated library and plugins for mathematical morphology with ImageJ. Bioinformatics 32, 3532–3534 (2016).

Haase, R. et al. CLIJ: GPU-accelerated image processing for everyone. Nat. Methods 17, 5–6 (2020).

Abdullayev, A., Kamm, P. H., Bekheet, M. F. & Gurlo, A. Fabrication and characterization of ice templated membrane supports from Portland cement. Membranes 10, 93 (2020).

Henning, L. M. et al. Manufacturing and characterization of highly porous bioactive glass composite scaffolds using unidirectional freeze casting. Adv. Eng. Mater. 19, 1700129 (2017).

Püspöki, Z., Storath, M., Sage, D. & Unser, M. in Focus on Bio-Image Informatics (eds. De Vos, W. H., Munck, S. & Timmermans, J.-P.) 69–93 (Springer, 2016).

Ashby, M. F. The properties of foams and lattices. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 364, 15–30 (2006).

Gibson, L. J. & Ashby, M. F. Cellular Solids: Structure and Properties (Cambridge Univ. Press, 1997).

Hua, M. et al. Strong tough hydrogels via the synergy of freeze-casting and salting out. Nature 590, 594–599 (2021).

Delattre, B. et al. Impact of pore tortuosity on electrode kinetics in lithium battery electrodes: study in directionally freeze-cast LiNi0.8Co0.15Al0.05O2 (NCA). J. Electrochem. Soc. 165, A388 (2018).

Miao, S., Wang, Y., Sun, L. & Zhao, Y. Freeze-derived heterogeneous structural color films. Nat. Commun. 13, 4044 (2022).

Shao, G., Hanaor, D. A. H., Shen, X. & Gurlo, A. Freeze casting: from low-dimensional building blocks to aligned porous structures — a review of novel materials, methods, and applications. Adv. Mater. 32, 1907176 (2020).

Liu, Y., Zhu, W., Guan, K., Peng, C. & Wu, J. Freeze-casting of alumina ultra-filtration membranes with good performance for anionic dye separation. Ceram. Int. 44, 11901–11904 (2018).

Du, Z. et al. The sound absorption performance of the highly porous silica ceramics prepared using freeze casting method. J. Am. Ceram. Soc. 103, 5990–5998 (2020).

Bian, R. et al. Ultralight MXene-based aerogels with high electromagnetic interference shielding performance. J. Mater. Chem. C. 7, 474–478 (2019).

Li, P.-X. et al. Bidirectionally aligned MXene hybrid aerogels assembled with MXene nanosheets and microgels for supercapacitors. Rare Met. 42, 1249–1260 (2023).

Sani, E., Landi, E., Sciti, D. & Medri, V. Optical properties of ZrB2 porous architectures. Sol. Energy Mater. Sol. Cell 144, 608–615 (2016).

Huang, J. et al. Oriented freeze-casting fabrication of resilient copper nanowire-based aerogel as robust piezoresistive sensor. Chem. Eng. J. 364, 28–36 (2019).

Ezekwo, G., Tong, H.-M. & Gryte, C. C. On the mechanism of dewatering colloidal aqueous solutions by freeze-thaw processes. Water Res. 14, 1079–1088 (1980).

Tong, H. & Gryte, C. Mechanism of lamellar spacing adjustment in directionally frozen agar gels. Colloid Polym. Sci. 263, 147–155 (1985).

Campbell, J. J., Husmann, A., Hume, R. D., Watson, C. J. & Cameron, R. E. Development of three-dimensional collagen scaffolds with controlled architecture for cell migration studies using breast cancer cell lines. Biomaterials 114, 34–43 (2017).

Offeddu, G. S., Ashworth, J. C., Cameron, R. E. & Oyen, M. L. Multi-scale mechanical response of freeze-dried collagen scaffolds for tissue engineering applications. J. Mech. Behav. Biomed. Mater. 42, 19–25 (2015).

Schoof, H., Apel, J., Heschel, I. & Rau, G. Control of pore structure and size in freeze-dried collagen sponges. J. Biomed. Mater. Res. 58, 352–357 (2001).

Kuberka, M., Heschel, I. & Glasmacher, B. Preparation of collagen scaffolds and their applications in tissue engineering. Biomed. Tech. Eng. 47, 485–487 (2002).

Munier, P., Gordeyeva, K., Bergström, L. & Fall, A. B. Directional freezing of nanocellulose dispersions aligns the rod-like particles and produces low-density and robust particle networks. Biomacromolecules 17, 1875–1881 (2016).

Bai, H. et al. Biomimetic gradient scaffold from ice-templating for self-seeding of cells with capillary effect. Acta Biomater. 20, 113–119 (2015).

Bozkurt, A. et al. In vitro cell alignment obtained with a Schwann cell enriched microstructured nerve guide with longitudinal guidance channels. Biomaterials 30, 169–179 (2009).

Meghri, N. W. et al. Directionally solidified biopolymer scaffolds: mechanical properties and endothelial cell responses. JOM 62, 71–75 (2010).

Mohan, S. et al. Fluorescent reporter mice for nerve guidance conduit assessment: a high-throughput in vivo model. Laryngoscope 128, E386–E392 (2018).

von Heimburg, D. et al. Human preadipocytes seeded on freeze-dried collagen scaffolds investigated in vitro and in vivo. Biomaterials 22, 429–438 (2001).

Möllers, S. et al. Cytocompatibility of a novel, longitudinally microstructured collagen scaffold intended for nerve tissue repair. Tissue Eng. Part. A 15, 461–472 (2009).

Bozkurt, A. et al. Efficient bridging of 20 mm rat sciatic nerve lesions with a longitudinally micro-structured collagen scaffold. Biomaterials 75, 112–122 (2016).

Divakar, P. et al. High-plex expression profiling reveals that implants drive spatiotemporal protein production and innate immune activation for tissue repair. Acta Biomater. 138, 342–350 (2022).

Divakar, P., Moodie, K. L., Demidenko, E., Hoopes, P. J. & Wegst, U. G. K. Quantitative evaluation of the in vivo biocompatibility and performance of freeze-cast tissue scaffolds. Biomed. Mater. 15, 055003 (2019).

Divakar, P. et al. Design, manufacture, and in vivo testing of a tissue scaffold for permanent female sterilization by tubal occlusion. MRS Adv. 3, 1685–1690 (2018).

Jiang, S.-J. et al. Radially porous nanocomposite scaffolds with enhanced capability for guiding bone regeneration in vivo. Adv. Funct. Mater. 32, 2110931 (2022).

Yin, K. et al. Freeze-cast porous chitosan conduit for peripheral nerve repair. MRS Adv. 3, 1677–1683 (2018).

Divakar, P., Trembly, B. S., Moodie, K. L., Hoopes, P. J. & Wegst, U. G. K. in SPIE BIOS Proceedings Volume 10066 (ed. Ryan, T. P.) 100660A (2017).

Li, J. et al. Radial sponges facilitate wound healing by promoting cell migration and angiogenesis. Adv. Healthc. Mater. 12, 2202737 (2023).

Fu, Q., Rahaman, M. N., Dogan, F. & Bal, B. S. Freeze-cast hydroxyapatite scaffolds for bone tissue engineering applications. Biomed. Mater. 3, 025005 (2008).

Xia, Z. et al. Fabrication and characterization of biomimetic collagen–apatite scaffolds with tunable structures for bone tissue engineering. Acta Biomater. 9, 7308–7319 (2013).

Fu, Q., Rahaman, M. N., Dogan, F. & Bal, B. S. Freeze casting of porous hydroxyapatite scaffolds. I. Processing and general microstructure. J. Biomed. Mater. Res. B Appl. Biomater. 86B, 125–135 (2008).

Fu, Q., Rahaman, M. N., Dogan, F. & Bal, B. S. Freeze casting of porous hydroxyapatite scaffolds. II. Sintering, microstructure, and mechanical behavior. J. Biomed. Mater. Res. B Appl. Biomater. 86B, 514–522 (2008).

Yin, T. J. & Naleway, S. E. Freeze casting with bioceramics for bone graft substitutes. Biomed. Mater. Devices 1, 366–387 (2023).

Jackson, A. P., Vincent, J. F. V., Turner, R. M. & Alexander, R. M. The mechanical design of nacre. Proc. R. Soc. Lond. B Biol. Sci. 234, 415–440 (1988).

Deville, S., Saiz, E. & Tomsia, A. P. Ice-templated porous alumina structures. Acta Mater. 55, 1965–1974 (2007).

Launey, M. E. et al. Designing highly toughened hybrid composites through nature-inspired hierarchical complexity. Acta Mater. 57, 2919–2932 (2009).

Wegst, U. G. K., Bai, H., Saiz, E., Tomsia, A. P. & Ritchie, R. O. Bioinspired structural materials. Nat. Mater. 14, 23–36 (2015).

Roy, S., Frohnheiser, J. & Wanner, A. Effect of ceramic preform freeze-casting temperature and melt infiltration technique on the mechanical properties of a lamellar metal/ceramic composite. J. Compos. Mater. 54, 2001–2011 (2020).

Wegst, U. G. K., Allen, T. & Sridharan, K. Freeze-casting as a Novel Manufacturing Process for Fast Reactor Fuels. Final Report. DOE/NEUP–10-848, 1154737 (2014).

Zeng, Z., Wu, N., Liu, J. & Nyström, G. Mimicking biological architectures via freeze casting. Matter 5, 2519–2522 (2022).

Huang, L. et al. A compound scaffold with uniform longitudinally oriented guidance cues and a porous sheath promotes peripheral nerve regeneration in vivo. Acta Biomater. 68, 223–236 (2018).

Francis, N. L. et al. An ice-templated, linearly aligned chitosan-alginate scaffold for neural tissue engineering. J. Biomed. Mater. Res. A 101, 3493–3503 (2013).

Stokols, S. & Tuszynski, M. H. The fabrication and characterization of linearly oriented nerve guidance scaffolds for spinal cord injury. Biomaterials 25, 5839–5846 (2004).

Chen, J. et al. Freeze-casting osteochondral scaffolds: the presence of a nutrient-permeable film between the bone and cartilage defect reduces cartilage regeneration. Acta Biomater. 154, 168–179 (2022).

Stoppel, W. L., Hu, D., Domian, I. J., Kaplan, D. L. & Black, I. I. I. Anisotropic silk biomaterials containing cardiac extracellular matrix for cardiac tissue engineering. Biomed. Mater. Bristol Engl. 10, 034105 (2015).

Cao, S. et al. Shape memory and antibacterial chitosan-based cryogel with hemostasis and skin wound repair. Carbohydr. Polym. 305, 120545 (2023).

Wang, J., Xu, Z., Eloi, J.-C., Titirici, M.-M. & Eichhorn, S. J. Ice-templated, sustainable carbon aerogels with hierarchically tailored channels for sodium- and potassium-ion batteries. Adv. Funct. Mater. 32, 2110862 (2022).

Amin, R., Delattre, B., Tomsia, A. P. & Chiang, Y.-M. Electrochemical characterization of high energy density graphite electrodes made by freeze-casting. ACS Appl. Energy Mater. 1, 4976–4981 (2018).

Sun, H. et al. Hierarchical 3D electrodes for electrochemical energy storage. Nat. Rev. Mater. 4, 45–60 (2019).

Dang, D., Wang, Y., Gao, S. & Cheng, Y.-T. Freeze-dried low-tortuous graphite electrodes with enhanced capacity utilization and rate capability. Carbon 159, 133–139 (2020).

Thomas, B. et al. Ice-templating of lignin and cellulose nanofiber-based carbon aerogels: implications for energy storage applications. ACS Appl. Nano Mater. 5, 7954–7966 (2022).

Shao, Y. et al. 3D freeze-casting of cellular graphene films for ultrahigh-power-density supercapacitors. Adv. Mater. 28, 6719–6726 (2016).

Wilke, S. K. & Dunand, D. C. Structural evolution of directionally freeze-cast iron foams during oxidation/reduction cycles. Acta Mater. 162, 90–102 (2019).

Zhao, Z. et al. Sandwich, vertical-channeled thick electrodes with high rate and cycle performance. Adv. Funct. Mater. 29, 1809196 (2019).

Zhang, X. et al. Tunable porous electrode architectures for enhanced Li-Ion storage kinetics in thick electrodes. Nano Lett. 21, 5896–5904 (2021).

Lee, J. T., Jo, C. & De Volder, M. Bicontinuous phase separation of lithium-ion battery electrodes for ultrahigh areal loading. Proc. Natl Acad. Sci. USA 117, 21155–21161 (2020).

Huang, C. & Grant, P. S. Coral-like directional porosity lithium ion battery cathodes by ice templating. J. Mater. Chem. A 6, 14689–14699 (2018).

Azami-Ghadkolai, M., Yousefi, M., Allu, S., Creager, S. & Bordia, R. Effect of isotropic and anisotropic porous microstructure on electrochemical performance of Li ion battery cathodes: an experimental and computational study. J. Power Sources 474, 228490 (2020).

Noël, J. A. & White, M. A. Freeze-cast form-stable phase change materials for thermal energy storage. Sol. Energy Mater. Sol. Cell 223, 110956 (2021).

Andrews, E. W., Gioux, G., Onck, P. & Gibson, L. J. Size effects in ductile cellular solids. Part II: experimental results. Int. J. Mech. Sci. 43, 701–713 (2001).

Onck, P. R., Andrews, E. W. & Gibson, L. J. Size effects in ductile cellular solids. Part I: modeling. Int. J. Mech. Sci. 43, 681–699 (2001).

ASTM E9-09. Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature (ASTM International, 2018).

Abba, M. T., Hunger, P. M., Kalidindi, S. R. & Wegst, U. G. K. Nacre-like hybrid films: structure, properties, and the effect of relative humidity. J. Mech. Behav. Biomed. Mater. 55, 140–150 (2016).

Offeddu, G. S., Ashworth, J. C., Cameron, R. E. & Oyen, M. L. Structural determinants of hydration, mechanics and fluid flow in freeze-dried collagen scaffolds. Acta Biomater. 41, 193–203 (2016).

Liu, Y., Zhai, W. & Zeng, K. Study of the freeze casting process by artificial neural networks. ACS Appl. Mater. Interfaces 12, 40465–40474 (2020).

Ashby, M. F. Materials Selection in Mechanical Design (Elsevier, 2016).

Lao, W., Yin, K., Li, T. & Huang, H. BEANS: Property Chart Plotter. Zenodo https://doi.org/10.5281/zenodo.7261667 (2022).

Carlo, F. D. et al. TomoBank: a tomographic data repository for computational x-ray science. Meas. Sci. Technol. 29, 034004 (2018).

Liu, H., Jiang, J. & Zhai, W. Bubble freeze casting artificial rattan. Chem. Eng. J. 449, 137870 (2022).

Petersen, A. et al. A biomaterial with a channel-like pore architecture induces endochondral healing of bone defects. Nat. Commun. 9, 4430 (2018).

Chen, D. et al. Drilling by light: ice-templated photo-patterning enabled by a dynamically crosslinked hydrogel. Mater. Horiz. 6, 1013–1019 (2019).

Erlandsson, J. et al. On the mechanism behind freezing-induced chemical crosslinking in ice-templated cellulose nanofibril aerogels. J. Mater. Chem. A 6, 19371–19380 (2018).

Warburton, L. & Rubinsky, B. Freezing-modulated-crosslinking: a crosslinking approach for 3D cryoprinting. Bioprinting 27, e00225 (2022).

Nelson, I., Gardner, L., Carlson, K. & Naleway, S. E. Freeze casting of iron oxide subject to a tri-axial nested Helmholtz-coils driven uniform magnetic field for tailored porous scaffolds. Acta Mater. 173, 106–116 (2019).

Jha, P. K., Xanthakis, E., Jury, V. & Le-Bail, A. An overview on magnetic field and electric field interactions with ice crystallisation; application in the case of frozen food. Crystals 7, 299 (2017).

Parkin, K. L. & Fenema, O. R. (eds) Fennema’s Food Chemistry (CRC Press, 2007).

Guan, J., Porter, D., Tian, K., Shao, Z. & Chen, X. Morphology and mechanical properties of soy protein scaffolds made by directional freezing. J. Appl. Polym. Sci. 118, 1658–1665 (2010).

Deville, S. et al. Ice shaping properties, similar to that of antifreeze proteins, of a zirconium acetate complex. PLoS ONE 6, e26474 (2011).

Deville, S., Meille, S. & Seuba, J. A meta-analysis of the mechanical properties of ice-templated ceramics and metals. Sci. Technol. Adv. Mater. 16, 043501 (2015).

Hautcoeur, D. et al. Thermal conductivity of ceramic/metal composites from preforms produced by freeze casting. Ceram. Int. 42, 14077–14085 (2016).

Pawelec, K. M., Husmann, A., Best, S. M. & Cameron, R. E. A design protocol for tailoring ice-templated scaffold structure. J. R. Soc. Interface 11, 20130958 (2014).

Labconco Corporation. A Guide to Freeze Drying for the Laboratory (2010).

Tang, Y., Miao, Q., Qiu, S., Zhao, K. & Hu, L. Novel freeze-casting fabrication of aligned lamellar porous alumina with a centrosymmetric structure. J. Eur. Ceram. Soc. 34, 4077–4082 (2014).

Barnett, E., Angeles, J., Pasini, D. & Sijpkes, P. Robot-assisted Rapid Prototyping for ice structures. in 2009 IEEE International Conference on Robotics and Automation, 146–151 (2009).

Acknowledgements

The authors gratefully acknowledge financial support through NASA awards 80NSSC18K0305 and 80NSSC21K0039 (U.G.K.W.) and NSF-CMMI award 1538094 (U.G.K.W.), the DFG Reinhart-Koselleck Project 408321454, Ba 1170/40 (F.G.-M) and BMBF award 05K18KTA (F.G.-M), the Alexander von Humboldt Foundation for a Humboldt Research Fellowship (K.Y.).

Author information

Authors and Affiliations

Contributions

Introduction (U.G.K.W., P.H.K., K.Y. and F.G.-M.); Experimentation (U.G.K.W., P.H.K., K.Y. and F.G.-M.); Results (U.G.K.W., P.H.K., K.Y. and F.G.-M.); Applications (U.G.K.W., P.H.K., K.Y. and F.G.-M.); Reproducibility and data deposition (U.G.K.W., P.H.K., K.Y. and F.G.-M.); Limitations and optimizations (U.G.K.W., P.H.K., K.Y. and F.G.-M.); Outlook (U.G.K.W., P.H.K., K.Y. and F.G.-M.); overview of the Primer (U.G.K.W., P.H.K., K.Y. and F.G.-M.).

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Methods Primers thanks Qunfeng Cheng, Hao Bai, Seog-Young Yoon, Lennart Bergström and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Related links

Ansys Granta Selector: https://www.ansys.com/en-gb/products/materials/granta-selector

Dragonfly: https://www.theobjects.com/dragonfly/index.html

Freezecasting.net: http://www.freezecasting.net/

Matricel: https://www.matricel.com/

Tomoscopy experiments database: http://resolution.tomoscopy.net

Tomoscopy.net: http://www.tomoscopy.net/

Supplementary information

43586_2024_307_MOESM2_ESM.avi

Supplementary Video 1. Unidirectional solidification of a cylindrical freeze-cast specimen. Shown is the unidirectional solidification of a section of the cylindrical sample in a 2 mm diameter polyimide tube observed for 267 s. The video illustrates the dynamics of crystal growth and solution templating during freeze casting. The solidified ice crystals are shown in blue and the ice-templated sucrose phase in yellow. The solidification front advances with an average velocity of ~11 μm s−1. Domains are defined by differences in lamellar orientation. The process was imaged at one tomoscopy per second. The video plays at 10 frames per second. Video is reprinted from ref. 34, CC BY 4.0 (https://creativecommons.org/licenses/by/4.0/).

43586_2024_307_MOESM3_ESM.avi

Supplementary Video 2. Growth of an extracted single ice lamella. The video shows the crystal growth of a single ice lamella from one of the central domains in a unidirectionally solidifying 3% w/v sucrose in water solution. In the 267 s shown, different types of secondary instability form unilaterally on the side of the ice lamella, which faces the cold end of the mould; the sometimes transient nature of the instabilities is noteworthy. The lamella expands in thickness and width with increasing height owing to a decrease in the local cooling rate, \(\dot{C}\). The slight directional changes at about t = 70 s and t = 150 s from 4.4° to 10°, respectively, is paralleled by the formation of secondary instabilities and the lamella splitting into two. The video plays at 10 frames per second. Video is reprinted from ref. 34, CC BY 4.0 (https://creativecommons.org/licenses/by/4.0/).

43586_2024_307_MOESM4_ESM.avi

Supplementary Video 3. Evolution of ice-templated structure. The video shows the structural evolution of the ice-templated sucrose lamella for 160 s. It is noteworthy that the progressing freezing front pushes surface features, in this case a jellyfish cap array along with it parallel to the direction of solidification. Also shown is the formation of first attached, then detached, tentacle-like features. The video plays at nine frames per second. Video is reprinted from ref. 34, CC BY 4.0 (https://creativecommons.org/licenses/by/4.0/).

43586_2024_307_MOESM5_ESM.avi

Supplementary Video 4. Formation of a Jellyfish Cap array with Tentacles. Shown in this video at high magnification is the formation over 30 s of first attached, then detached, tentacle-like surface features extending from the jellyfish cap array parallel to the freezing direction. The video plays at ten frames per second. Video is reprinted from ref. 34, CC BY 4.0 (https://creativecommons.org/licenses/by/4.0/).

Glossary

- Anisotropy

-

Anisotropic crystal growth is characterized by growth characteristics that depend on crystallographic direction. Freeze-cast materials tend to be anisotropic. Their solvent-templated structure and, as a result, also their properties vary with the direction of loading. When their properties are unique in three mutually perpendicular directions, the material is called orthotropic.

- Applied cooling rate

-

The rate at which the temperature decreases per unit time, \({\dot{C}}_{\mathrm{app}}\), at the cold source.

- Attenuation coefficient

-

A measure of how easily X-rays can penetrate a material, given by the fraction of incident photons in a mono-energetic beam that are attenuated per unit thickness of that material.

- Dendritic ice crystal growth

-

Branched or tree-like crystal growth.

- Directional solidification

-

Controlled crystal growth in a well-defined direction determined by the applied thermal gradient.

- Domain

-

A volume of solid, akin to a grain, wherein ice crystals and templated lamellae exhibit the same orientation and alignment, respectively.

- Extensional shear flow

-

The 9% volumetric expansion of water upon solidification into ice results in an interdendritic extensional shear flow. An additional thermal mould contraction can enhance this flow when batch processing. The extensional shear flow contributes to the preferential alignments of components during directional solidification.

- Field of view

-

(FOV). The projected area imaged. The FOV corresponds to the region of interest, usually measured in pixels.

- Freeze casting

-

Directional solidification of solvent-based solutions or slurries, followed by the removal of the solvent in its solid state by sublimation or solvent exchange.

- Freezing front velocity

-

The speed of progression of the solid–liquid interface, in dendritic crystal growth defined by the crystal tip array.

- Greyscale

-

A synonym for the range of voxel values within a slice, volume or tomographic data set.

- Hierarchical pore architecture

-

Porosity at different length scales contributed by different levels of the hierarchy. In freeze-cast materials, the hierarchical pore architecture is frequently composed of particle porosity, porosity in the cell walls and porosity defined by the cell walls of the cellular solid.

- Ice templating

-

The shaping of the solute phase by ice crystals growing from an aqueous solution or slurry.

- Instability

-

For example, a crystal instability forms when a planar solid–liquid interface is perturbed and a stable array of dendrites starts to form.

- Lamellar spacing

-

The periodic lamellar spacing defines how coarse or fine the structure of a freeze-cast material is. It is defined as λ = S + w, the sum of the short pore axis, S, and the cell wall thickness, w. The lamellar spacing depends on the local cooling rate, \(\dot{C}\).

- Local cooling rate

-

The rate at which the temperature decreases per unit time, \(\dot{C}\), at a well-defined position within the sample.

- Nucleation

-

Nucleation is the formation of a small cluster (or nucleus) of atoms. Once a critical number of atoms assemble, crystal growth begins. Homogeneous ice nucleation can occur in the liquid phase and heterogeneous nucleation on the cooled mould surface.

- Partially faceted crystal growth

-

Crystal growth that is faceted in some directions and not faceted in others.

- Phase contrast

-

Contrast in a radiograph or tomogram resulting from the difference in phase developed by beams as they pass through an object.

- Phase separation

-

Two or more phases forming from a single phase mixture of components.

- Pore size

-

The pore size is defined by its cross-sectional area, A, the length of the short, S, and long, L, pore axes, their aspect ratio, R, and the cell wall thickness, w.

- Principal component analysis

-

(PCA). A statistical technique used to analyse the variability of a multidimensional data set. PCA is used to identify the dominant patterns in the data and analyse the 3D spatial orientation of the segmented objects. This is typically done by projecting the voxel coordinates of that object onto a lower-dimensional subspace that captures the most significant variations in the data.

- Projections

-

Radiographs of an object acquired at a given angle of illumination that, when combined with many others, provide the data to numerically reconstruct the object. Typically, between 100 and 3,600 projections are used to reconstruct a tomogram.

- Thermal gradient

-

G, the rate at which the temperature varies per unit distance in a well-defined direction, a 3D vector.

- Tomogram

-

Originally, a 2D slice through an object reconstructed computationally from a sinogram. Now often used to refer to the 3D reconstructed sample volume.

- Tomograms per second

-

Unit of temporal resolution, used for the recording speed of continuous full tomograms in a tomoscopic experiment.

- Voxel

-

Abbreviation for volume element; the basic unit of a 3D digital representation of a volume or object. Voxel size should not be confused with spatial resolution.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wegst, U.G.K., Kamm, P.H., Yin, K. et al. Freeze casting. Nat Rev Methods Primers 4, 28 (2024). https://doi.org/10.1038/s43586-024-00307-5

Accepted:

Published:

DOI: https://doi.org/10.1038/s43586-024-00307-5