Abstract

Biodegradable plastics have been proposed as an alternative to conventional plastics for many applications, such as single-use plastic bags, disposable cutleries and tablewares, and agricultural plastic mulch films. However, concerns have arisen about environmental sustainability of biodegradable plastics, especially regarding degradability, generation of biodegradable micro- and nanoplastics, and release of additives. Here, we critically evaluate literature on the degradation and ecotoxicity of biodegradable plastics with the consideration of environmentally relevant concentrations. Our evaluation suggests that, provided with proper disposal and full biodegradation, biodegradable plastics, including biodegradable micro- and nanoplastics, would not accumulate substantially in the environment and would be far from reaching concentrations at which negative impacts on ecosystems can be expected. In addition, we highlight existing regulatory efforts to prevent adverse ecotoxicity of biodegradable plastics. To ensure timely biodegradation under various disposal conditions, we propose to calibrate the actual biodegradability in disposal environments against the intrinsic biodegradability in standards. Further, we recommend to supplement biodegradability certificates on biodegradable plastics with clear disposal instructions, to ensure proper end-of-life management. With proper testing, comprehensive labeling, and effective management, we believe that, for certain applications, biodegradable plastics are a promising substitute for conventional plastics.

Similar content being viewed by others

Introduction

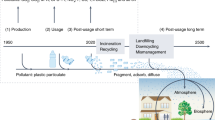

Plastic has become ubiquitous in our daily lives due to its low cost, versatility, and convenience. The annual use of plastic was estimated to be 490 million tons in 2023, and is forecasted to reach 765 million tons by 20401. The widespread usage of plastic has contributed to an enormous amount of plastic waste and led to profound plastic pollution in the environment. Global plastic waste was estimated to be 375 million tons per year in 2023, and reaching 615 million tons per year in 20401. Only 12% of this waste is currently incinerated and only 9% is recycled2. A substantial portion of the plastic waste ends up in the environment; the load of plastic waste to aquatic ecosystems is projected to be 29 million tons per year in 20402.

Plastic pollution poses serious risks to ecosystems: large plastic pieces, such as fishnets and plastic bags, have been found to entangle or suffocate marine animals; while small plastic debris, mainly micro- and nanoplastics, have been found to be swallowed or inhaled by other animals and human beings, potentially causing tissue damage, cytotoxicity, and systemic dysfunction3,4,5. Facing the increasing threats from plastic pollution, the United Nations has pledged to develop an international plastics treaty by the end of 2024 to address the challenges related to the lifecycle of plastics and reduce plastic waste6,7.

Solutions to the plastic problem are multifaceted and need to include the entire life-cycle of the plastics, from the production to the end-of-life, aligning with circular economy principles. Within the circular economy context, biodegradable plastics play an important role as a substitute for conventional plastics, particularly for single-use applications8,9. The main advantage of biodegradable plastics is that, after their intended use, they can be metabolized by microorganisms into CO2, CH4, and microbial biomass; thus, biodegradable plastics do not accrue an environmental footprint at their end-of-life. While recycling and reuse of conventional plastics also have a small end-of-life footprint, biodegradable plastics are particularly valuable where recycling and reuse are not readily feasible.

Biodegradable plastics have three main intended end-of-life scenarios: in-soil degradation, industrial composting, and anaerobic digestion8. In-soil degradation is the intended disposal option for agricultural soil-biodegradable plastic mulch films; industrial composting is used for compostable plastic waste, such as cutlery, shopping bags, and packaging materials; and anaerobic digestion is for non-compostable but anaerobically biodegradable plastic waste. During the degradation process, biodegradable plastics will gradually deteriorate into micro- and nanoplastics. These biodegradable micro- and nanoplastics will have a limited life time when they remain in their intended degradation environment. However, questions remain about the environmental impacts of these micro- and nanoplastics during their life time, before they ultimately completely degrade to CO2, CH4, and microbial biomass. Recent studies have shown that micro- and nanoplastics generated from biodegradable plastics have negative impacts on plants and aquatic organisms10,11. The promotion of biodegradable plastics as a viable alternative to conventional plastics has therefore been scrutinized recently12,13,14.

Here, we critically evaluate the literature on the environmental impacts of biodegradable plastics, including their degradation and ecotoxicity, and discuss their potentials as alternatives for conventional plastics. We consider proper disposal and full degradation, and we estimate the environmentally relevant concentrations of biodegradable plastics that can reasonably be expected in the environment. Additionally, we highlight regulatory requirements to prevent adverse impacts by biodegradable plastics on ecosystems.

Biodegradability standards and common biodegradable polymers

Standard test methods have been developed to test the biodegradability of materials in different environments. Such methods exist for testing aerobic biodegradation in different environments, such as soil15,16,17, municipal and industrial compost18, and marine waters19. For anaerobic biodegradation, there are test methods for high-solids anaerobic-digestion conditions20,21, anaerobic biodegradation in an aqueous system22, as well as accelerated landfill conditions23. All these methods are based on testing the conversion of plastic polymer carbon into gaseous carbon (CO2 and CH4) to determine the amount of biodegradation as function of time under controlled conditions.

Only after certain criteria of biodegradation have been fulfilled can a plastic material be labeled “biodegradable”, and more precisely as “biodegradable under specified conditions”. For composting, the ASTM-D6400 standard specification24 states that a plastic material can be labeled “compostable in aerobic municipal and industrial composting facilities” if, among other criteria, 90% of the organic carbon in the plastic is converted to CO2 within 180 days. Similarly, for labeling a “soil-biodegradable plastic mulch film”, the EN17033 specifications16 require that, among other conditions, at least 90% of the organic carbon in the film has to be converted to CO2 within 2 years, with the testing soil being natural and fertile, freshly collected from the field, and the test conducted at a constant temperature between 20 and 28 °C. Certification standards are under development for labeling biodegradable plastics as biodegradable in anaerobic digester25.

Common biodegradable polymers that meet the requirements in biodegradability standard specifications are summarized in Fig. 1. Polyhydroxyalkanoates (PHAs), including short-chain PHAs, such as poly(3-hydroxybutyrate) and poly(4-hydroxybutyrate) (PHB), and medium-chain PHAs, such as poly(3-hydroxyhexanoate) and poly(3-hydroxyoctanoate), are a group of aliphatic polyesters produced from fermentation of sugar and lipids, which can degrade readily in various environments, including marine water, fresh water, soil, and compost. Polylactic acid (PLA) is one of the most widely used bio-based and biodegradable plastic that is applied widely as packaging materials to produce disposable cups, bowls, and bottles26,27. Unfortunately, PLA only degrades readily in industrial composting as well as in anaerobic digesters at thermophilic temperatures28,29. Starch-based plastics are produced from thermoplastic starch that is lent with enhanced physical and mechanical properties, such as stiffness and strength. Cellulose-based plastics are produced from cellulose esters that are generated by processing cellulose with certain acids and anhydrides. Both starch and cellulose can biodegrade in all tested environments listed in Fig. 1. Poly(butylene succinate-co-adipate) (PBSA) can be produced from poly(butylene succinate) (PBS) synthesis by adding adipic acid to source materials30. PBSA is more easily biodegradable in soil and compost than PBS due to lower crystallinity and more flexible polymer chains31. Both PBSA and PBS can be produced from bio-based as well as fossil-based resources. Poly(butylene adipate terephthalate) (PBAT) is biodegradable in soil and compost, and it resembles the physical properties of linear low-density polyethylene, thus is widely used as agricultural mulch films and compostable shopping bags32,33. Although technologies exit to produce individual components, i.e., adipic acid, 1,4-butanediol, and terephthalic acid, from bio-based feedstocks34,35,36, 100% bio-based PBAT has not yet become commercially available.

Abbreviations: PHA polyhydroxyalkanoates, PLA polylactic acid, PBSA poly(butylene succinate-co-adipate), PBS poly(butylene succinate), PBAT poly(butylene adipate terephthalate). *Polymers can be 100% bio-based, 100% fossil-based, or a blend of bio-based and fossil-based; **Polymer components can be 100% bio-based or 100% fossil-based, but currently, no commercially available PBAT is 100% bio-based. Figure adapted from https://renewable-carbon.eu/publications/product/biodegradable-polymers-in-various-environments-according-to-established-standards-and-certification-schemes-graphic-pdf/67, with permission from nova-Institute.

Thus, biodegradable polymers are not necessarily bio-based, and the biodegradability of biodegradable polymers depends on their intrinsic properties as well as the biodegradation environment. Only soil, industrial compost, and anaerobic digester should be regarded as the intended end-of-life options for biodegradable plastics, but not home compost, freshwater, marine environment, nor landfills. Home composting has been shown neither effective nor environmentally beneficial in a citizen science study involving 9,701 citizens in the UK37. Participants failed to follow the instruction to only compost plastic items certified as “home compostable” and put industrial compostable and non-labeled plastics into home composters. Home composting tests showed that 60% of the certified home compostable plastics did not degrade effectively due to diverse settings and variations of home composting conditions.

While freshwater and marine waters are natural environments like soil, greater challenges arise when it comes to monitor the loading of biodegradable plastic waste in aquatic systems compared to soil, due to the interconnected nature of these aquatic systems, amplifying the transport potential of biodegradable plastic waste. And even the “OK Biodegradable Marine” certificate clearly states that the certification is only to add environmental value to the products (e.g., fishing line, fishing baits, and cull panel) that may accidentally release into the marine environment, but not to promote the discarding of plastic products into the marine environment38.

Biodegradability of biodegradable plastics in the environment

The biodegradability standards ensure that the polymers in biodegradable plastics can be converted to CO2, CH4, or biomass, under certain conditions as specified in the standard protocols. These test conditions are usually highly favorable for biodegradation, i.e., large surface area of the plastics (plastics can be tested in powder form), and optimal moisture and temperature. As such, biodegradation standards ensure the “intrinsic” biodegradability of the plastic polymers. However, the standards do not guarantee that a certified biodegradable plastic will actually biodegrade in a less controlled natural environment within the specified timeframe as described in biodegradability specifications.

Field studies, where degradation was assessed by measuring surface area or mass of plastics remaining, have confirmed that soil-biodegradable plastic mulch films degrade in soil after they have been tilled into the ground, but that the degradation is slower than that under controlled laboratory conditions39,40. On the other hand, it is also possible for biodegradable plastics to take less time to attain the biodegradation thresholds specified in biodegradability tests. For example, Sintim et al.41 reported that no visible plastic residues were left after 126 days of composting in an on-farm compost pile, for a PBAT mulch film and a PLA/PHA blend mulch film. Yu et al.13 found that 100% of the visible surface area of two PBAT/PLA mulch films disappeared after 56 days of composting in an on-farm compost. Although the determination of biodegradation via visual observation of surface area is not equivalent to the carbon conversion method in biodegradability standards, the findings of these two studies suggest that the 90% conversion of organic carbon to CO2 can be reached in less than 180 days as specified by the composting biodegradation standard24.

To ensure timely biodegradation is achieved without compromising soil, compost, or digestate quality, there is a need for a standard test to assess the biodegradation of biodegradable plastics under real-world conditions for soil, industrial compost, and anaerobic digester. In soils and industrial compost, the real-world tests could comprise of the meshbag method to determine surface area and mass of plastic remaining13,41,42, and the meshbag method calibrated against the laboratory CO2 test (Fig. 2). For soil biodegradation, the meshbag method would have to be calibrated locally for a given soil and climate. While for anaerobic digestion, methane generation can be monitored directly with biochemical methane potential assay25.

Environmental concerns about generation of micro- and nanoplastics

During biodegradation, biodegradable plastics fragment into smaller and smaller pieces, generating micro- and nanoplastics13,39,43. The generation rate of micro- and nanoplastics is generally faster for biodegradable plastics than that for conventional plastics44,45, and the generation of micro- and nanoplastics is, in fact, an integral step in the biodegradation process. However, generation of micro- and nanoplastics from biodegradable plastics is a double edged sword: it is a desired process that increases surface area and promotes biodegradation substantially; yet, the micro- and nanoplastics may negatively impact the environment before they completely degrade.

Important questions that need to be answered are (1) how much micro- and nanoplastics is produced, (2) how long is the residence time of these micro- and nanoplastics, and (3) would the amount and the residence time cause negative environmental impacts. To answer these questions, we consider the biodegradation of plastic mulch films in soils as an example. Agricultural soils are one of the biggest reservoirs of micro- and nanoplastics in terrestrial systems, and are the intended end-of-life environment for soil-biodegradable plastic mulch films. According to Griffin-Lahue et al.40, we assume that it takes 5 years for a soil-biodegradable plastic mulch film to fully biodegrade (equivalent to an average of 20% biodegradation per year). If a soil-biodegradable plastic mulch film is applied every year, and it takes 5 years for the mulch to completely biodegrade, then there will always be a certain amount of biodegradable plastic residing in the soil.

We can estimate the anticipated concentration of micro- and nanoplastics as a result of repeated mulch applications as follows: a single application of a typical soil-biodegradable plastic mulch film with a thickness of 15 μm and a density of 1250 kg/m3 will result in a plastic load of 18.8 g/m2 16,46. If we assume a soil bulk density of 1200 kg/m3 and a soil depth of 0.2 m for tillage during soil-incorporation of soil-biodegradable plastic mulch films40, we calculate a mass concentration of 0.078 g-plastic/kg-soil (= 0.0078% w/w), right after tillage. As the plastic degrades, the plastic concentration will decrease, but increase again after the next years plastic mulch film is tilled into the ground. Repeated yearly mulch applications and an average biodegradation rate of 20% per year result in a steady-state concentration of three times the initial concentration13, i.e., a maximal plastic concentration of 56.3 g/m2 or 0.23 g/kg (= 0.023% w/w). Even with the biodegradation rate being 10% per year, the maximal plastic mass concentration in soil would be 0.43 g/kg (= 0.043% w/w) for the residual biodegradable plastics at steady state.

A similar calculation is used in the EN17033 standard to determine the concentration for ecotoxicity tests, which include emergence and growth of plants, mortality, biomass, and reproduction of earthworms, as well as microbial nitrification activity16. For these toxicity tests, a concentration of 1% w/w, which is about 2 orders of magnitude higher than what can reasonably be expected under realistic field conditions, is chosen to be the initial loading of biodegradable plastic to prepare the test soil16. Further, the test soil is incubated until significant biodegradation occurs for the biodegradable plastic, and then used for ecotoxicity tests, to ensure that no adverse effects on soil ecosystems are caused by both the biodegradable plastic and the residual biodegradation products16.

Although certified soil-biodegradable plastics does not show ecotoxicity at an initial concentration of 1% w/w according to EN17033, other studies have reported negative impacts of soil-biodegradable plastics when using different ecotoxicity endpoints. For example, Qi et al.47 added PBAT microplastics to a sandy soil and observed significant effects on soil physical and chemical parameters at 1 and 2% w/w plastic concentrations. Qi et al.48 found higher abundances of bacteria genera (e.g., Bacillus and Variovorax) and changes in soil pH, electrical conductivity, and C:N ratio, due to the addition of micro-sized soil-biodegradable plastic pieces at 1% w/w. Zhou et al.49 reported that biodegradable microplastics made of PHA at 10% w/w altered soil ecological functioning and biogeochemical cycling. Negative impacts of PBAT on plants were reported at microplastic concentrations of 0.1% w/w for maize50, 1% w/w for wheat51, 1% w/w for rice52, 2% w/w for Arabidopsis53, and at macroplastic concentrations of 0.5% w/w for soybean54 and 4.5% for tomato and lettuce11.

Given that 1% w/w initial concentration as chosen in the EN17033 is already far above expected concentrations, any findings with concentrations > 1% w/w should not be used to assess the ecotoxicty of soil-biodegradable plastics. Besides, the residual soil-biodegradable plastics at the steady state will consist of macro- micro-, and nanoplastics with various sizes, shapes, and biodegradation levels, conditions which are not considered in most experimental studies about the impacts of biodegradable plastics on soil health47,48,49,51. To the best of our knowledge, no negative impacts on soil ecosystems have been reported at concentrations < 0.1% w/w for micro- and nanoplastics derived from in-situ biodegradation of soil-biodegradable plastics. Nonetheless, scholars have concluded from reported negative findings that “it is still too early to promote biodegradable mulch film on a large scale”14, or “biodegradable plastics seem to be a new threat to environmental health rather than an effective solution to counteract microplastic pollution”55.

Other than residing in soils, biodegradable micro- and nanoplastics generated from soil-biodegradable plastic mulch can be transported off-site to aquatic and atmospheric environments. As soil-biodegradable plastic mulch is only designed to biodegrade in soils, where microbial activity is much richer than air and water, concerns have arisen that soil-biodegradable micro- and nanoplastics would turn into persistent micro- and nanoplastics in water or air. It is also presumable that other biodegradable plastic products, such as compostable bags, could contribute to persistent micro- and nanoplastics, once they are off-site transported to non-intended disposal environments. For example, Liao et al.44 reported that soil-biodegradable PBAT and compostable PLA mainly went through photo-degradation in air and only lost 1.1% and 0.8% in weight after 6 months, respectively.

These are valid concerns; nonetheless, questions remain about under which conditions and to what extent will biodegradable plastics be introduced to non-intended disposal environments. Learning the lessons from plastic pollution caused by inappropriate disposal of conventional plastics, our society should ensure that biodegradable plastic waste must be properly managed and disposed of, thus only accidental release of biodegradable plastics to non-intended disposal environments would be of concern.

Release of additives

Concerns have also arisen about the release of additives, such as fillers, plasticizers, colorants, and UV-stabilizers, from biodegradable plastics during degradation41,56,57. While this release of additives is an expected process of the biodegradation in the environment, the released additives could pose environmental threats. Standards, such as EN17033 and ASTM-D6400, prescribe maximal concentrations of heavy metals and substances of very high concern58 to ensure biodegradable plastics do not introduce hazardous substances into the environment16,24. Nonetheless, non-biodegradable additives, such as carbon black and TiO241,57, may accumulate overtime and could potentially cause negative impacts on the ecosystems.

Potentials of biodegradable plastics

It is important to recognize that it is challenging for biodegradable plastics to biodegrade rapidly and completely in various natural environments, yet to retain their mechanical properties during their purpose-intended life span to satisfy consumers’ demands. For instance, a soil-biodegradable plastic mulch film needs to remain intact enough during the early stage of the growing season to provide the intended agronomic benefits to plants, but then needs to degrade rapidly enough after till-in to ensure no lasting accumulation and negative impacts on soil and plant health. Further, additives in the biodegradable plastics should be monitored for the potential accumulation in the environment and subsequent impacts on ecosystems.

Current information suggests that macro- and microplastics generated from biodegradable plastics can cause harm to terrestrial or aquatic organisms; however, the negative environmental impacts are only observed at concentrations much higher than what can be reasonably expected under proper management and disposal of biodegradable plastic waste, that is, when the biodegradable plastics are disposed of according to their intended end-of-life scenario. To date, there are limited amount of scientific data that are obtained with environmentally relevant plastic concentrations and realistic practices, but there is so far no indication that biodegradable plastics would cause harm to ecosystem functioning.

In addition, it is necessary to acknowledge that biodegradable plastic is not a silver bullet, but it can be a better and more sustainable choice over conventional plastics and other non-biodegradable materials in applications where recycling and reuse of the material are not readily feasible. In the light of increasing awareness of plastic pollution, legislation has been passed banning or taxing certain single-use conventional plastic products. For example, single-use plastic bags bans have been issued to regulate the usage of single-use plastic shopping bags. However, such bans or taxes do not necessarily always contribute to their intended reduction of plastic use and pollution, but rather cause unintended consequences, as consumers seek other alternatives, such as paper bags and cloth bags.

Studies have demonstrated that single-use plastic shopping bags have the lowest environmental footprints compared to paper and cloth bags59,60. In addition, single-use plastic shopping bags are frequently used more than once, for instance, as liners for small trash cans61. While banning or taxing single-use plastic shopping bags is effective in reducing the consumption of these plastic shopping bags62,63, consumers will need to buy single-use conventional plastic bags as trash liners instead62,64,65. In Portugal, the use of single-use plastic shopping bags decreased by 74% after imposing a tax on the bags, while the consumption of reusable plastic bags increased by 61%; and at the same time, the consumption of garbage bags increased by 12% because consumers reused the plastic bags for shopping bags instead of garbage liners 64. Conversion from single-use plastic shopping bags to paper and cloth bags can also increase risks for food borne illness65. Given these external, and certainly not intended, consequences of plastic policies, it is worth considering to exclude biodegradable plastics from bans on single-use plastic products66. A single-use or reusable biodegradable plastic shopping bag will almost certainly have a smaller environmental impact than a reusable conventional plastic bag66.

Recommendations and policy implications

Biodegradable plastics are a promising substitute for conventional plastics, especially for single-use products. Currently, only few biodegradable polymers are available, and they have different material properties and biodegradability. For instance, PLA is similar in properties to high density polyethylene or polypropylene, while PBAT is similar to low density polyethylene. PLA is more stiff and thus can used to make dishes and cutlery, while PBAT is flexible and can be used to make plastic bags and agricultural mulch films. PLA only biodegrades in industrial compost and in thermophilic anaerobic digesters, while PBAT biodegrades in soil and industrial compost. Thus, biodegradable plastics have to be chosen for appropriate applications and managed with the intended end-of-life scenario in mind.

Appropriate laboratory tests and standards for that purpose exist, but in-field tests and standards still need to be developed and ratified to ensure that biodegradation indeed occurs under real environmental conditions in a timely manner for the intended use. For the successful implementation of biodegradable plastics, regulatory agencies should undertake a series of measures, including (1) control additives in biodegradable plastics to mitigate potential adverse environmental impacts; (2) enforce biodegradability certification of biodegradable plastic products, indicating their compliance with specific certification standards; (3) provide disposal instructions for biodegradable plastics, aligned with their intended end-of-life scenarios; and (4) ensure adequate processing capacity and accessibility of industrial composting and anaerobic digestion facilities.

Without proper end-of-life management, biodegradable plastics would lose their advantages over conventional plastics, and there is no need for another painful lesson on plastic pollution from inappropriate disposal of biodegradable plastic waste. Non-managed terrestrial and aquatic ecosystems are not, and should not be, an intended end-of-life destination for biodegradable plastics. With proper design, testing, labeling, and management, we are confident that our society can harness the potentials of biodegradable plastics to curb global plastic pollution.

References

OECD. Global Plastics Outlook: Policy Scenarios to 2060. (Organisation for Economic Co-operation and Development, Paris, France, 2022) https://doi.org/10.1787/aa1edf33-en.

United Nations. Drowning in Plastics—Marine Litter and Plastic Waste Vital Graphics. (United Nations Environment Programme, New York, 2021) https://www.unep.org/resources/report/drowning-plastics-marine-litter-and-plastic-waste-vital-graphics. Accessed December 1, 2023.

Tan, H., Yue, T., Xu, Y., Zhao, J. & Xing, B. Microplastics reduce lipid digestion in simulated human gastrointestinal system. Environ. Sci. Technol. 54, 12285–12294 (2020).

Li, Y. et al. Inhaled tire-wear microplastic particles induced pulmonary fibrotic injury via epithelial cytoskeleton rearrangement. Environ. Int. 164, 107257 (2022).

Li, Y. et al. Potential health impact of microplastics: a review of environmental distribution, human exposure, and toxic effects. Environ Health 1, 249–257 (2023).

United Nations. Historic Day in the Campaign to Beat Plastic Pollution: Nations Commit to Develop A Legally Binding Agreement. (United Nations Environment Programme, New York, 2022) https://www.unep.org/news-and-stories/press-release/historic-day-campaign-beat-plastic-pollution-nations-commit-develop. Accessed December 1, 2023.

Boerner, L. K. Negotiations on international plastic pollution treaty to wrap up this year. C&EN 102, 35 (2024).

Flury, M. & Narayan, R. Biodegradable plastic as integral part of the solution to plastic waste pollution of the environment. Curr. Opin. Green Sustain. Chem. 30, 100490 (2021).

Yu, Y. et al. Biodegradable plastics as alternatives for polyethylene mulch films. Adv. Agron. 183, 121–192 (2024).

González-Pleiter, M. et al. Secondary nanoplastics released from a biodegradable microplastic severely impact freshwater environments. Environ. Sci. Nano 6, 1382–1392 (2019).

Serrano-Ruiz, H., Martin-Closas, L. & Pelacho, A. M. Impact of buried debris from agricultural biodegradable plastic mulches on two horticultural crop plants: tomato and lettuce. Sci. Total Environ. 856, 159167 (2023).

Viera, J. S. et al. Are biodegradable plastics an environmental rip off? J. Hazard. Mater. 416, 125957 (2021).

Yu, Y., Griffin-LaHue, D. E., Miles, C. A., Hayes, D. G. & Flury, M. Are microplastics from biodegradable plastic mulches an environmental concern? J. Hazard. Mater. Adv. 4, 100024 (2021).

Liu, L. et al. It is still too early to promote biodegradable mulch film on a large scale: a bibliometric analysis. Environ. Technol. Innov. 27, 102487 (2022).

ASTM-D5988. Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials in Soil. (ASTM International, West Conshohocken, PA, 2018).

EN-17033. Plastics—Biodegradable Mulch Films for Use in Agriculture and Horticulture—Requirements and Test Methods. (European Standard, European Committee for Standardization, Brussels, Belgium, 2018).

ISO-23517. Plastics—Soil Biodegradable Materials for Mulch Films for Use in Agriculture and Horticulture—Requirements and Test Methods Regarding Biodegradation, Ecotoxicity and Control of Constituents. (International Organization for Standardization, Geneva, Switzerland, 2021).

ASTM-D5338. Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials Under Controlled Composting Conditions, Incorporating Thermophilic Temperatures. (ASTM International, West Conshohocken, PA, 2021).

ASTM-D6691-17. Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials in the Marine Environment by a Defined Microbial Consortium or Natural Sea Water Inoculum. (ASTM International, West Conshohocken, PA, 2017).

ASTM-D5511. Standard Test Method for Determining Anaerobic Biodegradation of Plastic Materials Under High-Solids Anaerobic-Digestion Conditions. (ASTM International, West Conshohocken, PA, 2018).

ISO-15985. Plastics—Determination of the Ultimate Anaerobic Biodegradation under High-solids Anaerobic-digestion Conditions. (International Organization for Standardization, Geneva, Switzerland, 2014).

ISO-14853. Plastics—Determination of the Ultimate Anaerobic Biodegradation of Plastic Materials in an Aqueous System. (International Organization for Standardization, Geneva, Switzerland, 2016).

ASTM-D5526-18. Standard Test Method for Determining Anaerobic Biodegradation of Plastic Materials Under Accelerated Landfill Conditions. (ASTM International, West Conshohocken, PA, 2018).

ASTM-D6400-23. Standard Specification for Labeling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities. (ASTM International, West Conshohocken, PA, 2023).

Cazaudehore, G. et al. Can anaerobic digestion be a suitable end-of-life scenario for biodegradable plastics? A critical review of the current situation, hurdles, and challenges. Biotechnol. Adv. 56, 107916 (2022).

Tait, M., Pegoretti, A., Dorigato, A. & Kalaitzidou, K. The effect of filler type and content and the manufacturing process on the performance of multifunctional carbon/poly-lactide composites. Carbon 49, 4280–4290 (2011).

Fambri, L., Dorigato, A. & Pegoretti, A. Role of surface-treated silica nanoparticles on the thermo-mechanical behavior of poly(lactide). Appl. Sci. 10, 6731 (2020).

Zaborowska, M. et al. Multi-faceted analysis of thermophilic anaerobic biodegradation of poly (lactic acid)-based material. Waste Manag. 155, 40–52 (2023).

Gadaleta, G. et al. Assessment of methane production, disintegration, and biodegradation potential of bioplastic waste in anaerobic digestion systems. J. Environ. Chem. Eng. 12, 111658 (2024).

Niaounakis, M. Biopolymers: Processing and Products. (William Andrew, New York, 2014).

Nath, D., Pal, A. K., Misra, M. & Mohanty, A. K. Biodegradable blown film composites from bioplastic and talc: effect of uniaxial stretching on mechanical and barrier properties. Macromol. Mater. Eng. 308, 2300214 (2023).

Fredi, G. & Dorigato, A. Recycling of bioplastic waste: a review. Adv. Ind. Eng. Polym. Res. 4, 159–177 (2021).

Tullo, A. H. The Biodegradable Polymer PBAT is Hitting the Big Time, Volume 99. (Chemical & Engineering News, Washington DC, 2021).

Toray Industries, Inc. Toray Invents 100% Bio-Based Adipic Acid from Sugars Derived from Inedible Biomass, Scaling Up for Application to Eco-Friendly Nylon 66. (Toray Industries, Inc., Tokyo, Japan, 2022) https://www.toray.com/global/news/details/20220818103248.html. Accessed January 15, 2024.

Cargill. Cargill and HELM Partner to Build $300M Commercial-Scale, Renewable BDO Facility, First in the Us, to Meet Growing Customer Demand. (Cargill, Incorporated, Minneapolis, MN, 2021) https://www.cargill.com/2021/cargill-and-helm-partner-to-build-$300m-facility. Accessed January 15, 2024.

Tachibana, Y., Kimura, S. & Kasuya, K. Synthesis and verification of biobased terephthalic acid from furfural. Sci. Rep. 5, 8249 (2015).

Purkiss, D., Allison, A. L., Lorencatto, F., Michie, S. & Miodownik, M. The big compost experiment: Using citizen science to assess the impact and effectiveness of biodegradable and compostable plastics in uk home composting. Front. Sustain. 3, 942724 (2022).

TÜV-Austria. OK Biodegradable Marine. (TÜV Austria Belgium, Kraainem, Belgium, 2019) https://www.tuv-at.be/green-marks/certifications/ok-biodegradable/.

Sintim, H. Y. et al. In situ degradation of biodegradable plastic mulch films in compost and agricultural soil. Sci. Total Environ. 727, 138668 (2020).

Griffin-LaHue, D. E. et al. In-field degradation of soil-biodegradable plastic mulch films in a Mediterranean climate. Sci. Total Environ. 806, 150238 (2022).

Sintim, H. Y. et al. Release of micro- and nanoparticles from biodegradable plastic during in situ composting. Sci. Total Environ. 675, 686–693 (2019).

Li, C. et al. Degradation of potentially biodegradable plastic mulch films at three diverse US locations. Agroecol. Sustain. Food Syst. 38, 861–889 (2014).

Li, S., Ding, F., Flury, M. & Wang, J. Dynamics of macroplastics and microplastics formed by biodegradable mulch film in an agricultural field. Sci. Total Environ. 894, 164674 (2023).

Liao, J. & Chen, Q. Biodegradable plastics in the air and soil environment: low degradation rate and high microplastics formation. J. Hazard. Mater. 418, 126329 (2021).

Wei, X., Bohlén, M., Lindblad, C., Hedenqvist, M. & Hakonen, A. Microplastics generated from a biodegradable plastic in freshwater and seawater. Water Res. 198, 117123 (2021).

Degli-Innocenti, F. The pathology of hype, hyperbole and publication bias is creating an unwarranted concern towards biodegradable mulch films. J. Hazard. Mater. 463, 132923 (2024).

Qi, Y. et al. Impact of plastic mulch film debris on soil physicochemical and hydrological properties. Environ. Pollut. 266, 115097 (2020).

Qi, Y. et al. Effects of plastic mulch film residues on wheat rhizosphere and soil properties. J. Hazard. Mater. 387, 121711 (2020).

Zhou, J. et al. The microplastisphere: biodegradable microplastics addition alters soil microbial community structure and function. Soil Biol. Biochem. 156, 108211 (2021).

Sun, H. et al. Effects of polyethylene and biodegradable microplastics on photosynthesis, antioxidant defense systems, and arsenic accumulation in maize (Zea mays L.) seedlings grown in arsenic-contaminated soils. Sci. Total Environ. 868, 161557 (2023).

Qi, Y. et al. Macro- and micro-plastics in soil-plant system: effects of plastic mulch film residues on wheat (Triticum aestivum) growth. Sci. Total Environ. 645, 1048–1056 (2018).

Yang, C. & Gao, X. Impact of microplastics from polyethylene and biodegradable mulch films on rice (Oryza sativa L.). Sci. Total Environ. 828, 154579 (2022).

Liu, J. et al. Negative effects of poly(butylene adipate-co-terephthalate) microplastics on Arabidopsis and its root-associated microbiome. J. Hazard. Mater. 437, 129294 (2022).

Li, B. et al. Effects of plastic particles on germination and growth of soybean (Glycine max): a pot experiment under field condition. Environ. Pollut. 272, 116418 (2021).

Malafeev, K. V., Apicella, A., Incarnato, L. & Scarfato, P. Understanding the impact of biodegradable microplastics on living organisms entering the food chain: a review. Polymers 15, 3680 (2023).

Serrano-Ruiz, H., Eras, J., Martin-Closas, L. & Pelacho, A. M. Compounds released from unused biodegradable mulch materials after contact with water. Polym. Degrad. Stab. 178, 109202 (2020).

Yu, Y. et al. Enhanced transport of TiO2 in unsaturated sand and soil after release from biodegradable plastic during composting. Environ. Sci. Technol. 56, 2398–2406 (2022).

ECHA. Candidate List of Substances of Very High Concern for Authorisation. (European Chemicals Agency, Helsinki, Finland, 2016) https://echa.europa.eu/candidate-list-table. Accessed January 25, 2024.

Ahamed, A. et al. Life cycle assessment of plastic grocery bags and their alternatives in cities with confined waste management structure: a Singapore case study. J. Clean. Prod. 278, 123956 (2021).

Tan, Y. et al. Single-use plastic bag alternatives result in higher environmental impacts: multi-regional analysis in country with uneven waste management. Waste Manag. 171, 281–291 (2023).

Wagner, T. P. Reducing single-use plastic shopping bags in the USA. Waste Manag. 70, 3–12 (2017).

Nielsen, T. D., Holmberg, K. & Stripple, J. Need a bag? A review of public policies on plastic carrier bags—where, how and to what effect? Waste Manag. 89, 428–440 (2019).

Adeyanju, G. C. et al. Effectiveness of intervention on behaviour change against use of non-biodegradable plastic bags: a systematic review. Discov. Sustain. 2, 13 (2021).

Martinho, G., Balaia, N. & Pires, A. The Portuguese plastic carrier bag tax: the effects on consumers’ behavior. Waste Manag. 61, 3–12 (2017).

Montalbano, S. The Problems with Plastic Bag Bans: A Policy Brief. (Alaska Policy Forum, Anchorage, AK, 2019) https://alaskapolicyforum.org/2019/09/problems-bag-bans-brief/. Accessed December 31, 2023.

Cucina, M. The lesser of two evils: enhancing biodegradable bioplastics use to fight plastic pollution requires policy makers interventions in europe. Environ. Impact Assess. Rev. 103, 107230 (2023).

nova-Institute. Biodegradable Polymers in Various Environments According to Established Standards and Certification Schemes. (nova-Institut für politische und ökologische Innovation GmbH, Hürth, Germany, 2021) https://renewable-carbon.eu/publications/product/biodegradable-polymers-in-various-environments-according-to-established-standards-and-certification-schemes-graphic-pdf/. Accessed December 10, 2023.

Acknowledgements

This work was supported by NSF Grant 2152514 from the NSF-EAR Geobiology and Low-Temperature Geochemistry program, NIFA Agroecosystems Grant 2020-67019-31149/1022234, NIFA Grant 2020-67019-31167/1022800, W4188 Multi-State Hatch Project, and USDA/SCRI Award 2022-51181-38325.

Author information

Authors and Affiliations

Contributions

Conceptualization: Y.Y., M.F. Roles/Writing—original draft: Y.Y., M.F. Visualization: Y.Y., M.F. Writing—review & editing: Y.Y., M.F.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yu, Y., Flury, M. Unlocking the Potentials of Biodegradable Plastics with Proper Management and Evaluation at Environmentally Relevant Concentrations. npj Mater. Sustain. 2, 9 (2024). https://doi.org/10.1038/s44296-024-00012-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44296-024-00012-0