Abstract

Heterojunctions play a crucial role in improving the absorption of visible light and performance of photocatalysts for organic contaminants degradation in water. In this work, a novel type-II–II Ag2CO3/Bi2WO6 (AB) heterojunction was synthesized by hydrothermal reaction and in situ-precipitation methods. The mechanisms of charge transfer and carrier separation at the interface of heterojunctions and the influence on the photocatalytic activity were investigated. The degradation of levofloxacin (LEV) under visible light irradiation was employed to evaluate the photocatalytic performance of AB. The results showed that 85.4% LEV was degraded by AB, which was 1.38 and 1.39 times higher than that of Bi2WO6 and Ag2CO3, respectively. The work functions of the different crystal planes in the AB heterojunction, which was calculated by density functional theory, are a significant difference. The Fermi energy (Ef) of Ag2CO3 (− 6.005 eV) is lower than Bi2WO6 (− 3.659 eV), but the conduction band (CB) is higher. Therefore, using AB heterojunctions as an example, the research explored the mechanism of type-II–II which CB and Ef of one semiconductor cannot simultaneously surpass those of another material, based on the built-in electric field theory. Through this analysis, a deeper understanding of type-II heterojunctions was achieved, and providing valuable insights into the behavior of this specific heterojunction system.

Similar content being viewed by others

Introduction

With the rapid development of modern industry, the issue of environmental pollution is receiving more and more attention, particularly the contamination of water by organic pollutants, such as antibiotic1,2. Antibiotics are widely used in the treatment of broad-spectrum bacterial infections in both humans and animals3. However, owing to their high metabolism rates, a substantial portion of antibiotics is excreted through faeces4. Subsequently, these antibiotics, in various forms and to varying extents, enter into the environment, giving rise to the proliferation of drug-resistant bacteria and drug-resistant genes, thereby causing a significant public health risk to humans5. Therefore, there exists an urgent need to adopt an efficient, rapid, and cost-effective method to treat the issue of antibiotics remediation in water.

Photocatalytic technology has attracted the attention of many scholars as a sustainable and efficient technology for the removal of antibiotics from water6. The main mechanism of photocatalytic degradation involves that the photocatalyst absorbs photons, leading to the generation electrons (e−) and holes (h+) on its surface. This e− and h+ can induce O2 and water molecules in the solution to participate in redox reactions that yield superoxide radicals (·O2−) and hydroxyl radicals (·OH). ·O2−, ·OH and h+, which have strong redox capacity, directly can engage in the degradation of antibiotics. Through a series of reactions, organic pollutants can be degraded into carbon dioxide, water, or smaller molecular compounds to achieve the purpose of pollutant removal.

Bismuth-based photocatalysts have attracted extensive attention due to their high charge separation efficiency and efficient use of solar light7. Due to its unique layered structure, suitable band gap and high photochemical stability, Bi2WO6 is considered a promising semiconductor photocatalyst for use in the field of photocatalytic degradation8,9,10,11. However, the photocatalytic performance of Bi2WO6 is greatly hindered by the high recombination rate of the photogenerated carriers during the transfer process. Various approaches have been explored to enhance the performance of photocatalysts, including ion doping, noble metals-loading, morphology modulation, and heterojunction assembly12,13,14,15. Notably, the construction of heterojunction has emerged as an effective strategy to solve the problem of rapid carrier recombination while expanding the range of visible light absorption. Feng Wei et al. synthesized BiOI/Bi2WO6 nanocomposites, which achieved a 99% degradation of methylene blue (MB) under simulated visible light irradiation, representing a 30% improvement over Bi2WO616. Similarly, Yang Jun et al. successfully prepared Bi2WO6/BiOCl heterojunctions using a one-step hydrothermal method, and reached a 93.3% degradation rhodamine B, a 33% enhancement compared to Bi2WO617. These studies demonstrate that the construction of heterojunction structures can significantly enhance the photocatalytic activity of Bi2WO6.

Ag2CO3, known for its good visible light absorption and photocatalytic activity, is also a noteworthy photocatalyst that has attracted substantial attention18. In order to overcome the shortcomings of photo-corrosion and electron–hole pair recombination, researchers have dedicated considerable efforts to investigating the construction of heterostructures involving Ag2CO3, such as Ag2CO3/TiO219, Ag2CO3/Ag/AgBr20, WO3/Ag2CO321, Ag2CO3/SnFe2O422, Ag2CO3/CeO223, Ag2CO3/BiOBr/CdS24, among others. These studies have paved the way for novel heterostructure designs aimed at enhancing the stability and photocatalytic performance of Ag2CO3.

To elucidate the impact of heterojunctions on photocatalytic activity, scientists have categorized them into three types: straddling (type-I), staggered (type-II), and gap-breaking (type-III), based on the relative positions of the energy bands of the materials25,26,27. About the conventional explanation of type-II heterojunction, e− tends to accumulate in the photocatalyst with a more positive conduction band (CB) potential, while h+ transfers to the material with more negative valence band (VB) potential, and enhances light absorption and facilitates charge separation. However, from the kinetic point of view, there is a repulsive force between e− and between h+, posing challenges for the migration of charges in the heterojunction theory. In recent years, with the rapid development in the field of photocatalysis, the role of the built-in electric field (IEF) in the transfer of photogenerated carriers has been recognized28,29,30,31. IEF is mainly determined by the Fermi level (Ef) of the two materials forming the heterojunction. Considering the distribution of the CB and the Ef, the type II heterojunction can be classified into two types: (i) CB and Ef of one semiconductor are higher than those of another, it is named type-II–I in the article; (ii) CB and Ef of one semiconductor cannot simultaneously surpass those of another material, it is named type-II–II. Figure 1 is detailed interpretation of the above-mentioned. Regarding the carrier transfer mechanism of type-II–I heterojunction, scholars have offered an explanation based on the IEF theory32. However, the photocatalytic mechanism of type-II–II heterojunction remains unexplored. Therefore, we focused on type-II–II heterojunctions and used Ag2CO3 and Bi2WO6 to prepare it, where the CB and Ef of Ag2CO3 are not higher than those of Bi2WO6 simultaneously. By investigating the carrier transfer process, we aim to shed light on the influence of the Ef on the IEF of the heterojunction in the type-II–II heterojunction.

In this work, Ag2CO3/Bi2WO6 (AB) nanocomposites were prepared by hydrothermal and in situ precipitation methods. The structure and properties of the materials were characterized and analyzed. The photocatalytic degradation performance of the nanocomposites towards levofloxacin (LEV) was investigated to evaluate their activity, stability, and applicability. The transfer mechanism of photogenerated carriers in AB heterojunctions was explored by density-functional theory (DFT) to improve the existing understanding of type-II heterojunctions and provide valuable insights into the behavior of this specific heterojunction system.

Materials and methods

Reagents

Bismuth nitrate pentahydrate (Bi(NO3)3‧5H2O), sodium tungstate dihydrate (Na2WO4‧2H2O), p-benzoquinone (BQ), ethylenediaminetetraacetic acid (EDTA), sodium carbonate (Na2CO3) and isopropanol (IPA) were purchased from Shanghai Macklin Biochemical Technology Co. Nitric acid and silver nitrate (AgNO3) were provided by Sinopharm Chemical Reagent Co. All reagents are analytical grade and do not require further purification. Deionized water (18 μS cm−1) was used for all experiments.

Preparation of photocatalysts

Bi2WO6 nanosheets were prepared by a hydrothermal method. Initially, 0.97 g of Bi(NO3)3‧5H2O was dispersed in 30 mL of 0.5 mol/L nitric acid solution and stirred for 1 h until completely dissolved. Subsequently, 0.33 g Na2WO4‧2H2O was added into 30 mL of deionized water, completely dissolved, and then added dropwise into Bi(NO3)3 solution, stirred for 1 h. The resulting suspension was transferred into 80 mL of Teflon-lined stainless autoclave and heated at 160 °C for 18 h. Afterward, the obtained product was washed thrice with deionized water, and the yellow precipitate was dried in an oven at 60 °C for 12 h.

A in situ-precipitation method was used to fabricate AB nanocomposites. Specifically, 2 g of Bi2WO6 nanoflakes were dispersed in 20 mL of deionized water, and subjected to ultrasonication for 30 min. Subsequently, 14.3 mL of AgNO3 solution (0.10 M) was added to the above suspension and stirred for 30 min under dark conditions to promote the adsorption of silver ions on the surface of Bi2WO6. Then, an equal volume of Na2CO3 solution (0.05 M) was added and the mixture was stirred for 4 h under dark conditions. The resulting sample was washed three times, filtered, and then dried at 60 °C for 12 h. Once sufficiently dried, the sample was ground and bagged.

In the above AB nanocomposites, the theoretical mass fraction of Ag2CO3 was 9%, labeled as AB-9. The other nanocomposites (AB-1, AB-3, AB-5, AB-7 and AB-11) with different masses fractions of Ag2CO3 (1%, 3%, 5%, 7% and 11%) were prepared by adjusting the volumes of AgNO3 (1.5 mL, 4.5 mL, 7.5 mL, 10.9 mL, and 18 mL) and Na2CO3 (1.5 mL, 4.5 mL, 7.5 mL, 10.9 mL, and 18 mL). The synthesis of Ag2CO3 followed the same way described above, only without the addition of Bi2WO6.

Photocatalyst characterization

The crystal structure and surface morphology of the photocatalysts were characterized and analyzed by X-ray powder diffraction (XRD) (China, Puxi General Instrument, XD3) and field emission scanning electron microscopy (SEM) (Germany, ZEISS, Sigma 300). An ultraviolet–visible spectrophotometer (UV–Vis) (Japan, Shimadzu, UV-360Oi Plus) was used to analyze the photo response ability of the samples with a scanning range of 200–800 nm. X-ray photoelectron spectroscopy (XPS) (USA, Thermo Scientific, K-Alpha) was used to examine the surface composition, the valence information, and the surface chemical bonding states of the samples. In addition, the separation efficiency of carriers was evaluated by a fluorescence spectrometer (China, Gangdong Sci &Tech F-380). A 3-electrode electrochemical analysis approach was used for electrochemical impedance spectroscopy (EIS) using an electrochemical workstation (China, Chenhua Instrumen, CHI 660E). The intermediates produced during the process of degradation of LEV were measured and analyzed by liquid chromatography-tandem mass spectrometry (LC–MS) (Japan, Shimadzu, LCMS-8050). The degree of mineralization of LEV was measured by total organic carbon (TOC) (Japan, Shimadzu, TOC-L).

Photocatalytic degradation experiment

To evaluate the photocatalytic performance of AB nanocomposites, the degradation of LEV was conducted in a temperature-controlled photochemical reactor (NAI-GHY-DSGKW) equipped with multiple tubes. A 500 W xenon lamp (illuminance: 1369 W/m2) was employed to simulate the visible light irradiation. Before photocatalytic degradation, 0.05 g of photocatalyst was added into 50 mL solution of LEV (10 mg/L), and stirred under dark conditions for 60 min to reach the adsorption–desorption equilibrium. Then, the light source was turned on to carry out the photocatalytic reaction. At certain time intervals, a 3.0 mL sample was withdrawn from the photoreactor and filtered through a 0.45 µm membrane. The concentration of LEV was determined using UV–vis at a wavelength of 288 nm. To fit the LEV degradation data and calculate the rate constant (k) of LEV degradation, a pseudo-primary kinetic model was employed. In addition, IPA, BQ, and EDTA were added as scavengers of ·OH, ·O2−, and h+, respectively, to investigate the contribution of different radicals to the photocatalytic degradation of LEV. The concentration of all three trapping agents were 1.0 mmol/L. ·O2– and ·OH were checked by electron spin resonance (ESR) (Germany, Bruker Corporation, Bruker EMX plus,) with 5,5-dimethyl-1-pyrroline N-oxide (DMPO).

DFT calculations

In this paper, the state density, band structure, and work function of the materials have been calculated using the Materials Studio 2020 (MS) software package based on DFT. The interactions between electrons and ions are described using the projector augmented wave (PAW) method, and the exchange–correlation potential is treated using the PBE generalization in the generalized gradient approximation (GGA). The convergence criteria for the energy and interatomic forces are 10−5 eV and 0.01 eV/Å, respectively.

Results and discussion

Morphology, structure, and elemental analysis of AB

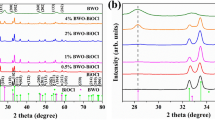

The XRD patterns of Ag2CO3, Bi2WO6 and AB nanocomposites are shown in Fig. 2. Six diffraction peaks of Ag2CO3 appear at 18.56°, 20.52°, 32.59°, 33.64°, 37.05°, and 39.57°, corresponding to crystal planes (0 2 0), (1 1 0), (− 1 0 1), (1 3 0), (2 0 0) and (0 3 1), respectively. These results are consistent with the known diffraction pattern of Ag2CO3 (PDF#70-2184)33. The diffraction peaks of Bi2WO6 (PDF#39-0256) are at 28.3°, 32.67°, 46.9°, and 55.82°, corresponding to (1 3 1), (0 6 0), (2 6 0), and (3 3 1) crystal planes, respectively34. Importantly, no diffraction peaks associated with impurities were observed, indicating that the prepared materials have high crystallinity and purity, as shown in Fig. 2a. In Fig. 2b, the XRD pattern of AB nanocomposites reveals primarily the diffraction peaks Bi2WO6, with the emergence of characteristic peaks of Ag2CO3 as the Ag2CO3 content in the material increased. This observation confirms that AB nanocomposites were successfully synthesized.

SEM images of Bi2WO6, Ag2CO3, and AB-9 photocatalyst are presented in Fig. 3. Bi2WO6 exhibits nanosheets with smooth surfaces, forming an overall irregular polyhedral morphology with multiple crevices, as shown in Fig. 3a and b. Ag2CO3, on the other hand, appears as cuboid and micro-spherical particles with smooth surfaces, as illustrated in Fig. 3c and d. The SEM images of the AB-9 reveal a tight bonding between Ag2CO3 and Bi2WO6, forming a new pore structure, as shown in Fig. 3e and f. Figure 4 displays the energy dispersive spectrometer (EDS) spectrum of the AB-9. The presence of Ag, C, W, Bi, and O, is observed in the spectrum. Furthermore, the elements are uniformly distributed throughout the AB-9, indicating successful preparation of the AB nanocomposite. The morphology of AB-9 was further studied by the TEM, as shown in Fig. 5a. TEM images show that the Bi2WO6 nanosheets are closely covered by Ag2CO3, which confirms the growth of Ag2CO3 nanoparticles on Bi2WO6. Figure 5b is the HR-TEM image of Ag2CO3/Bi2WO6. the lattice spacing of 0.252 nm corresponds to the (− 2 0 1) crystal plane of Ag2CO3, and the lattice spacing of 0.207 nm corresponds to the (1 1 2) crystal plane of Bi2WO6. This is further evidence that the AB heterojunction was successfully constructed.

The chemical composition and elemental valence states of the AB-9 surface were analyzed by the XPS technique. Figure 6a displays the presence of Ag, C, O, Bi, and W elements in the nanocomposite AB-9, consistent with the EDS analysis. The fine spectra of Ag, C, O, Bi, and W elements are shown in Fig. 6b–f, respectively. In Bi2WO6, the characteristic peaks of Bi 4f. are observed as two strong peaks at 163.98 eV (Bi 4f7/2) and 158.68 eV (Bi 4f5/2), indicating the presence of Bi3+ ions35. The two independent peaks of W 4f. are 37.08 eV (W 4f5/2) and 34.88 eV (W 4f7/2), suggesting the existence of W6+ ions36. Comparatively, in the AB-9 nanocomposite, the binding energies of both Bi 4f. and W 4f. elements are higher than in Bi2WO6, suggesting that both Bi and W elements in Bi2WO6 lost electrons during the composite process with Ag2CO3.

In Ag2CO3, the Ag 3d spectrum exhibits two independent peaks of 373.58 eV (Ag 3d3/2, Ag+) and 367.58 eV (Ag 3d5/2, Ag+)22,37. The C 1s spectrum displays two distinct characteristic peaks of 288.38 and 284.18 eV, with the former mainly attributed to the C=O bonding in Ag2CO3, and the latter to the amorphous carbon38. By contrast, the binding energies of both Ag 3d and C 1s in the AB-9 are reduced. The O 1s spectrum of Bi2WO6 exhibits two peaks of 529.48 and 531.08 eV, corresponding to oxygen in the Bi–O and W–O bonds, respectively39. In the O 1s spectrum of Ag2CO3, the characteristic peak at 530.55 eV is attributed to the lattice oxygen, while the characteristic peak at 532.04 eV belongs to the adsorbed oxygen40. The increase in the binding energy of O 1s in the AB-9 suggests that the elemental oxygen loses electrons, possibly due to the changes in work function, lattice potential electronegativity difference, and other factors. However, undoubtedly, this phenomenon also confirms the existence of interaction between Bi2WO6 and Ag2CO3. In general, the binding energy of Bi2WO6 is shifted to the high-energy region, while that of Ag2CO3 is shifted to the low-energy region, indicating that the electron density of Bi2WO6 is lower and that of Ag2CO3 is higher within the AB-9. This also suggests that the electrons are transferred from Bi2WO6 to Ag2CO3 in the AB-9 upon contact between the two monomers. These results unequivocally demonstrate the successful combination of the two materials, and the formation of a heterojunction.

Photocatalytic performance of AB for LEV

The photocatalytic degradation performance of AB nanocomposites was assessed by examining the degradation effect on LEV under visible light irradiation. Figure 7a depicts the photocatalytic degradation rates of AB with varying mass fractions of Ag2CO3 for LEV. The experimental results showed that the LEV solution was stable without photocatalyst and did not decompose under visible light irradiation. Upon the addition of the photocatalyst to the LEV solution and subsequent stirring under dark conditions for 1 h, the reaction system reached the adsorption–desorption equilibrium. The specific details of dark adsorption are presented in Figure S1. At this time, the removal of LEV from the solution by Bi2WO6 and Ag2CO3 was determined to be 25.84 and 12.98%, respectively. This indicates that these two monomers exhibit superior adsorption capabilities for LEV, thereby providing abundant reaction sites in the photocatalytic degradation process. Following 60 min of xenon lamp irradiation, the degradation efficiencies of LEV solutions using Bi2WO6 and Ag2CO3 as photocatalysts were determined to be 61.56 and 61.4%, respectively. Notably, the degradation rate of LEV was significantly enhanced when nanocomposites containing different mass fractions of Ag2CO3 were used as photocatalysts. The degradation rates of AB-1, AB-3, AB-5, AB-7, AB-9, and AB-11 reached 76.49%, 73.89%, 79.67%, 81.61%, 85.4%, and 81.92%, respectively, with AB-9 exhibiting the highest photocatalytic capability during the process, surpassing that of the individual monomers. In the case of single photocatalysts, the recombination of e− and h+ was prone to occur under light conditions, resulting in lower photocatalytic activities of Bi2WO6 and Ag2CO3. However, when the two photocatalysts were combined to form a heterojunction, they exhibited an enhanced capacity for visible light and reduced the recombination of photogenerated carriers. The degradation rate of LEV by AB is significantly increased, confirming the beneficial effect of the heterojunction formed between Ag2CO3 and Bi2WO6 in improving the photocatalytic degradation process.

The degradation curve of LEV was fitted with the quasi-first-order kinetic equation -Ln(Ct/C0) = kt, as shown in Fig. 7b. Here, C0 and Ct represent the initial and instantaneous concentrations of LEV (mg/L), respectively, and k denotes the reaction kinetic constant that signifies the rate at which the degradation proceeds. The degradation rate constants for Bi2WO6, Ag2CO3, AB-1, AB-3, AB-5, AB-7, AB-9, and AB-11 were 0.0079, 0.0077, 0.0119, 0.0112, 0.0134, 0.0143, 0.0159, 0.0144 min−1, respectively. The variation in degradation rate aligns with the catalytic activity of the photocatalysts. AB-9 exhibited the highest degradation rate, which was approximately twofold that of Bi2WO6 and Ag2CO3 monomers.

AB-9, which has the best photocatalytic degradation effect, was employed as a photocatalyst to investigate the impact of AB dosage on LEV degradation. Figure 7c elucidates the influence of AB-9 dosage on the degradation rate of LEV. The degradation rate of LEV reached 84.55% when the dosage of AB-9 was increased from 0.01 to 0.05 g. However, with further increases in dosage, the degradation rate only exhibited a marginal improvement of 5.25%, reaching 89.8%. Similarly, the corresponding photocatalytic degradation rate constant k, as shown in Fig. 7d, exhibits a six-fold change with the addition of photocatalyst from 0.01 to 0.05 g, and a smaller change from 0.05 to 0.07 g. Although, increasing the photocatalyst dosage provides more active sites for the photocatalytic degradation reaction, excessive amounts of photocatalyst may hinder the transmission of light paths in the solution. This can impede its absorption ability for visible light and hinder the incident light irradiation from reaching the solution’s interior. Consequently, the number of photogenerated carriers decreases, thereby affecting the photocatalytic degradation performance of AB-9.

The pH of the solution is the main factor influencing the photocatalytic degradation of organic pollutants. Figure 8a and b shows the photocatalytic effect of AB-9 on LEV and the degradation rate constant k at varying pH. At pH 4.11 and 6.03, the degradation rate of LEV reached 86.72 and 84.48%, respectively, accompanied by the high degradation rate constants k. These results indicate that LEV can be degraded rapidly under environmental pH, showing excellent photocatalytic degradation ability. However, at pH 2.9, the degradation rate of LEV declined to 53%. The decline may be attributed to the fact that e- cannot stabilize under the highly acidic environment, and cannot further react to generate ·O2−. Moreover, the degradation rate of LEV was 65.56 and 37.51% at pH 9.2 and 11.15, respectively. Under alkaline conditions, h+ reacts with hydroxyl to form ·OH, which exhibits poor stability and participates in photocatalytic degradation in small amounts. As the alkalinity of the solution increases, the degradation of LEV further decreases, indicating that h+ may play a major role in the degradation process.

Wastewater usually contains a diverse array of inorganic anions, and the environment in which CO32−, Cl−, NO3−, and SO42− are present was simulated by adding Na2CO3, NaCl, NaNO3, and Na2SO4 to the solution. Figure 8c illustrates the effect of different anions on the photocatalyst degradation of LEV. Experimental results showed that the addition of SO42− and NO3− had minimal influence on the photocatalytic performance of the catalyst. However, the addition of Cl− reduced the photocatalytic ability to 64.22%. It is commonly believed that Cl− readily adsorbs on the catalyst surface, impeding the adsorption of reactant molecules and thereby inhibiting the reaction41. Following the addition of CO32−, the photocatalyst achieved a mere 27.16% degradation of LEV. This can be attributed to the reaction of h+ with CO32− generated by visible light excitation catalyst, resulting in h+ quenching and rendering it ineffective in the photocatalytic degradation reaction.

To further investigate the practical applicability of photocatalyst AB-9, several common pollutants were selected for degradation testing, and the results are shown in Fig. 8d. Under the same conditions employed for the photocatalytic degradation of LEV, AB-9 exerted a better degradation effect towards enrofloxacin (ENR) and ciprofloxacin (CIP), achieving degradation levels of 83.37 and 82.68%, respectively. By contrast, AB-9 exhibited less effectiveness in degrading rhodamine B (RhB) and methylene blue (MB). This disparity can mainly be attributed to the fact that ENR and CIP, being quinolone antibiotics with similar properties and stability as LEV, are more amenable to degradation with AB-9. On the other hand, MB and RhB, as common azo dyes, contain many conjugated structures that required higher energies of reactive radicals for degradation. Therefore, when compared to quinolone antibiotics, the photocatalyst AB-9 displays limited capability in degrading azo dyes.

The stability of the photocatalyst AB-9 was evaluated through the reusability experiment. After five cycles, the degradation activity of photocatalyst AB-9 on LEV exhibited a slight reduction, yet the degradation efficiency was still maintained at approximately 75%, as shown in Fig. 8e. To further explore the stability of the sample, the AB-9 was characterized by SEM (Figure S2) and XPS (Figure S3) before and after the reaction. The morphology and chemical composition of the sample before and after photocatalysis have negligible changes. It is further confirmed that the photocatalyst AB-9 is a relatively stable photocatalytic degradation material. In Table 1, this work is compared with the photocatalyst degradation of LEV reported in other literature. Compared with other degradation work, the photocatalyst prepared in this paper has a better degradation effect on LEV.

Optical properties of nanocomposite AB

To investigate the visible light absorption properties of Bi2WO6, Ag2CO3, and nanocomposite AB-9, the UV–vis diffuse reflectance spectroscopy (UV–vis-DRS) was employed for analysis. As shown in Fig. 9a, the absorption threshold of Bi2WO6 is approximately 456 nm, which indicates limited absorption of visible light, and restricts its photocatalytic performance. On the other hand, Ag2CO3 exhibits an absorption edge at around 545 nm, indicating a certain degree of visible light absorption capability. Upon combining the two photocatalytic components to form the AB-9 nanocomposite, the visible light absorption ability of the photocatalyst AB-9 is notably improved. This enhancement can be attributed to the synergistic interaction between the two photocatalysts.

Based on the crystal structures of Ag2CO3 and Bi2WO6 obtained by XRD analysis, and combined with DFT calculations, the energy bands of Ag2CO3 and Bi2WO6 were determined to be 0.779 and 2.019 eV, respectively, as shown in Fig. 9c and b. The highest occupied molecular orbital of Ag2CO3 is located at the high-symmetry point G, while the lowest unoccupied molecular orbital is situated at the high-symmetry point B, indicating that Ag2CO3 is an indirect bandgap semiconductor. Conversely, both the highest occupied molecular orbital and the lowest unoccupied molecular orbital of Bi2WO6 are positioned at the high symmetry point G, making it a direct bandgap semiconductor. It is worth noting that the bandgap obtained through GGA-PBE function tends to be smaller than the actual bandgap48. Analyzing the density of states of Bi2WO6 (Fig. 9d), it becomes evidently the CB is mainly contributed by O and Bi atoms, while the valence band (VB) originates from O and W atoms. On the other hand, examining the density of states of Ag2CO3 (Fig. 9e), it can be observed that the CB is mainly influenced by O and Ag atoms, while the VB is derived from Ag atoms.

To accurately determine the bandgap of the photocatalyst, the UV–vis-DRS data was processed using that Tauc equation αhυ = A (hυ–Eg)n/2. Where α is the absorption constant, h is Planck’s constant, υ is the optical frequency, A is the proportionality constant, Eg is the bandgap, and n is a constant associated with the semiconductor’s carrier leaps. For direct semiconductors, n = 1, while for indirect semiconductors, n = 4. The Tauc plots for Ag2CO3 and Bi2WO6, are shown in Fig. 10a and b. From these plots, it can be concluded that the band gaps of Ag2CO3 and Bi2WO6 are 2.06 and 2.94 eV, respectively. The valence band X-ray photoelectron spectra (VB-XPS) are presented in Fig. 10c and d, where the VB values of Ag2CO3 and Bi2WO6 are 1.59 and 2.53 eV, respectively. Additionally, the calculation yields the CB values of Ag2CO3 and Bi2WO6 as − 0.47 and − 0.41 eV, respectively.

The carrier separation efficiency was investigated using fluorescence spectroscopy, and the results are shown in Fig. 11a 49. The findings show that the emission peaks of both Bi2WO6 and Ag2CO3 monomers are higher than those of the nanocomposite AB. Notably, the emission peak intensity of Bi2WO6 is the highest, indicating that the recombination of e− and h+ pairs within Bi2WO6 occurs more easily. The emission peak intensity of Ag2CO3 is relatively low, possibly due to its nature as an indirect bandgap semiconductor. Comparatively, the nanocomposite AB-9 exhibits a reduced fluorescence intensity in comparison to Ag2CO3 and Bi2WO6 monomers. This suggests that the heterojunction formed between Ag2CO3 and Bi2WO6 significantly mitigates the carrier recombination rate. Subsequently, to further investigate the photoelectron transfer rate, EIS plots of Ag2CO3, Bi2WO6 and AB-9 were constructed in 0.1 Hz-0.1 M Hz. The equivalent circuit for the system is presented in the inset image of Figure S4. In this model, R0, R2, W3, and C1 respectively represent the resistance between the fluorine-doped tin oxide and catalysts, the charge migration resistance across the photoanode/electrolyte interface, the Warburg impedance, and the constant phase element50. In principle, a smaller EIS radius and R2 represent the faster the charge migration rate. In the EIS plots, AB-9 manifests a smaller arc radius and the lower R2 of 3933 Ω compared with Ag2CO3 (R2, 4031 Ω) and Bi2WO3 (R2, 5203 Ω), indicating the lowest charge-migration resistance and the best charge transfer effect.

Photocatalytic mechanism

To elucidate the degradation mechanism of the AB-9 nanocomposite on LEV under visible light, free radical capture experiments were conducted to identify the key free radicals involved in the degradation process. Scavenging of ·OH, ·O2− and h+ was performed with 5 mM of IPA, BQ and EDTA, respectively. The results, as seen in Fig. 11b, demonstrate that the degradation rate reached 86.25% when only the photocatalyst was added to the LEV solution. Upon the addition of EDTA, the degradation rate of LEV decreased significantly to 8.49%, indicating a 78% reduction. This confirms the crucial role of h+ in the degradation process of LEV. Furthermore, the introduction of BQ resulted in a 67% decrease in the degradation rate of LEV, indicating that ·O2− serves as a secondary reactive radical in the degradation process. When IPA was added, the degradation rate of LEV was unchanged, indicating that ·OH had little influence on the degradation process. In summary, the nanocomposite AB mainly employs h+ and ·O2− as the main contributors to the degradation of LEV.

To further explore the photocatalytic reaction mechanism, the ESR spectroscopy was carried out to determine the active species generated from the photocatalytic system with AB-9 as the photocatalyst, as shown in Fig. 11c and d. It should be noted that no peaks of DMPO- ·O2− and DMPO- ·OH are found according to the test data in the dark. However, upon 5 min of visible light irradiation, strong peak signals with an intensity ratio of 1:1:1:1 for DMPO- ·O2− were detected, indicating the generation of ·O2− radicals51. Furthermore, the DMPO-·OH spectrum fails to exhibit its characteristic peaks, so the process does not produce ·OH radicals. This result is consistent with that of the free radical capture experiment.

Based on the energy band distribution of the AB nanocomposite, it can be assigned to a type-II heterojunction. The conventional interpretation of the photogenerated carrier transfer path for type II heterojunction is shown in Fig. 12a. According to this interpretation, e− in the CB of Ag2CO3 drifts to the CB of Bi2WO6, while h+ in the VB of Bi2WO6 drifts to the VB of Ag2CO3, thus completing the separation of the photogenerated carriers. However, from the kinetic point of view, the repulsive forces between e− (or between h+) can hinder the transfer of the aforementioned assumptions.

In recent years, the influence of the IEF on the transfer of photogenerated carriers has been recognized by many researchers. It has been mainly employed to explain the cases involving heterojunctions formed by a semiconductor with both a higher CB and a higher Ef compared to another semiconductor, and type-II–I is appropriate for this. For type-II–II heterojunctions such as AB, where the photocatalytic performance can be improved compared to the monomer despite the CB and Ef of Ag2CO3 not being simultaneously higher than those of Bi2WO6, we attempted to provide a complementary analysis of the charge transfer mechanism of type-II–II heterojunctions based on the effect of the IEF on carrier migration.

The work function (Φ) of a material represents the work done for an electron to move from the Ef to the vacuum energy level (EV). DFT calculations reveal that Φ is 6.005 and 3.659 eV for the Ag2CO3 (1 3 0) and Bi2WO6 (1 3 1) facets, respectively, as shown in Fig. 12b and c. The Φ of the Ag2CO3 (1 3 0) facet is higher than the Bi2WO6 (1 3 1) facet, indicating that the Ef of Ag2CO3 is lower than that of Bi2WO6 (Fig. 12d). When Ag2CO3 and Bi2WO6 form a heterojunction, e− spontaneously transfers from Bi2WO6 to Ag2CO3 due to the different Ef (Fig. 12e). As the Ef of the two materials reach equilibrium, an electron depletion layer is formed on the Bi2WO6 side, and an electron accumulation layer is formed on the Ag2CO3 side, resulting in the formation of an IEF pointing from Bi2WO6 to Ag2CO3. The IEF distribution leads to the recombination of e− on the Ag2CO3 CB and h+ on the Bi2WO6 VB, meanwhile retaining the e− on the Bi2WO6 CB and h+ on the Ag2CO3 VB, which have a relatively low redox capacity (Fig. 12(f)). The CB potential of Bi2WO6 has a more negative value than that of O2/·O2− (− 0.33 eV), allowing the e− on the CB of Bi2WO6 to easily react with O2 (ad.) to form ·O2−. On the other hand, the VB potential of Ag2CO3 is not more positive than ·OH/OH− (2.23 eV), preventing the VB of Ag2CO3 from generating ·OH and participating in the photocatalytic reaction. Eventually, LEV was effectively degraded by ·O2− and h+.

Possible degradation pathways

To elucidate the photocatalytic degradation process of target pollutants, the intermediate products were further determined by high-performance liquid chromatography mass spectrometer (LC–MS). By analyzing the obtained results and considering previous studies, three possible photodegradation routes for LEV are depicted in Fig. 13 (detailed intermediates molecular formula seen in Table S1 and Figure S7). In pathway I, P1 is formed by piperazine ring cleavage of LEV (m/z = 362), and P2 is formed after dialdehyde group and defluorination. P2 may have been completely removed by decarboxylation or piperazine rings to produce P3 or P4. After quinolone ring cleavage and a series of reactions, P4 generates P5. In Pathway II, P6 is formed by decarboxylation of LEV. Subsequently, the quinolone ring in P6 is cleaved to form P7. Piperazine ring cleavage and demethylation form P8. In Pathway III, LEV is decarboxylated first, and then methyl groups are oxidized to form carboxyl groups, giving P9. After further decarboxylation, P10 is formed. After epoxidation of piperazine and cracking of the morpholine ring, P11 and P12 were formed. Finally, all the intermediates are mineralized into small organic molecules, carbon dioxide, and water after a multi-step oxidation reaction, and the photocatalytic degradation of LEV by AB-9 is achieved. Furthermore, the removal of total organic carbon (TOC) was studied (Figure S6). After the photocatalytic reaction for 60 min, the mineralization rate of the solution can reach 42.5%, which further indicates that the LEV can be finally completely mineralized into carbon dioxide and water.

Conclusion

In this paper, type-II heterojunction is classified into type-II–I and type-II–II considering the relative positions of CB and Ef in semiconductors. The transfer mechanism of photogenerated carriers in type-II–II heterojunction was investigated through the photocatalytic degradation of LEV by Ag2CO3/Bi2WO6 heterojunction.

The results show that the degradation rate of AB-9 to LEV reached 85.4% under the condition of visible light irradiation in 60 min. The degradation mechanism is illuminated by DFT calculation, which confirms the e− in Bi2WO6 transfer to Ag2CO3 at the heterojunction interface because the Ef (− 3.659 eV) of Bi2WO6 is higher than that of Ag2CO3 (− 6.005 eV). This calculation result is also demonstrated by the variation of the binding energy of elements in XPS. When the Ef is equal at the heterojunction interface, the electron depletion layer and accumulation layer are formed at the interface of Bi2WO6 and Ag2CO3, respectively, and thus an IEF is built from Bi2WO6 to Ag2CO3. Under the action of the IEF, e− in the CB of Ag2CO3 is recombined with h+ in the VB of Bi2WO6, meanwhile, h+ in the VB of Ag2CO3 and e− in the CB of Bi2WO6 is retained. The results of fluorescence spectra and EIS on the type-II–II heterojunction Ag2CO3/Bi2WO6 indicate that the separation of photogenerated carriers is significantly improved, which is circumstantial evidence of the formation of the IEF. The degradation ability of Ag2CO3/Bi2WO6 heterojunction to azo dyes with strong stability is slightly insufficient, which may be caused by the retention of free radicals with the weaker redox ability during the photogenerated carriers migration process in type II–II heterojunctions, and evidence the formation mechanism of the IEF. In general, we propose the classification of type-II heterojunctions and analyze the carrier transfer mechanism of type-II–II heterojunctions, which is an important supplement to the theory of type-II heterojunctions.

Data availability

All data that supports the findings of the study are available from the corresponding author with reasonable request.

References

Sarmah, A. K., Meyer, M. T. & Boxall, A. B. A global perspective on the use, sales, exposure pathways, occurrence, fate and effects of veterinary antibiotics (VAs) in the environment. Chemosphere 65, 725–759 (2006).

Anwer, H. et al. Photocatalysts for degradation of dyes in industrial effluents: Opportunities and challenges. Nano Res. 12, 955–972 (2019).

Gao, B., Li, P., Yang, R., Li, A. & Yang, H. Investigation of multiple adsorption mechanisms for efficient removal of ofloxacin from water using lignin-based adsorbents. Sci. Rep. 9, 637 (2019).

Saya, L. et al. A comprehensive review on recent advances toward sequestration of levofloxacin antibiotic from wastewater. Sci. Total Environ. 813, 152529 (2022).

Altaf, S. et al. Removal of levofloxacin from aqueous solution by green synthesized magnetite (Fe3O4) nanoparticles using Moringa olifera: Kinetics and reaction mechanism analysis. Ecotoxicol. Environ. Saf. 226, 112826 (2021).

Zhang, X. et al. In situ fabrication of a novel S-scheme heterojunction photocatalyts Bi2O3/P-C3N4 to enhance levofloxacin removal from water. Sep. Purif. Technol. 268, 118691 (2021).

Li, X. et al. Growth of BiOBr/ZIF-67 nanocomposites on carbon fiber cloth as filter-membrane-shaped photocatalyst for degrading pollutants in flowing wastewater. Adv. Fiber Mater. 4, 1620–1631 (2022).

Zhu, F. et al. Enhanced visible light photocatalytic performance with metal-doped Bi2WO6 for typical fluoroquinolones degradation: Efficiencies, pathways and mechanisms. Chemosphere 252, 126577 (2020).

Su, H. et al. Hydrothermal preparation of flower-like Ni2+ doped Bi2WO6 for enhanced photocatalytic degradation. J. Phys. Chem. Solids 170, 110954 (2022).

Zhao, H. et al. Interfacial bonded K-doped-C3N4@Bi2WO6 heterostructure for efficient photocatalytic degradation of tetracycline. J. Alloy. Compd. 972, 172822 (2024).

Cai, M., Liu, Y., Dong, K., Chen, X. & Li, S. Floatable S-scheme Bi2WO6/C3N4/carbon fiber cloth composite photocatalyst for efficient water decontamination. Chin. J. Catal. 52, 239–251 (2023).

Zhong, X. et al. Enhanced photocatalytic degradation of levofloxacin by Fe-doped BiOCl nanosheets under LED light irradiation. Chem. Eng. J. 383, 123148 (2020).

Li, Q. et al. Fabrication of 2D/2D g-C3N4/Au/Bi2WO6 Z-scheme photocatalyst with enhanced visible-light-driven photocatalytic activity. Appl. Surf. Sci. 508, 144182 (2020).

Shang, Y., Cui, Y., Shi, R. & Yang, P. Effect of acetic acid on morphology of Bi2WO6 with enhanced photocatalytic activity. Mater. Sci. Semiconduct. Process. 89, 240–249 (2019).

Kang, F. et al. Electron-rich biochar enhanced Z-scheme heterojunctioned bismuth tungstate/bismuth oxyiodide removing tetracycline. Inorg. Chem. Front. 10, 6045–6057 (2023).

Zhu, X. et al. Facile fabrication of BiOI/Bi2WO6 Z-scheme heterojunction composites with a three-dimensional structure for efficient degradation of pollutants. Arab. J. Chem. 16, 105286 (2023).

Liang, Z. et al. Visible light responsive Bi2WO6/BiOCl heterojunction with enhanced photocatalytic activity for degradation of tetracycline and rohdamine B. Inorg. Chem. Commun. 93, 136–139 (2018).

Liu, H. Y. et al. Facile assembly of g-C3N4/Ag2CO3/graphene oxide with a novel dual Z-scheme system for enhanced photocatalytic pollutant degradation. Appl. Surf. Sci. 475, 421–434 (2019).

Feng, C. et al. Effect of photo-corrosion of Ag2CO3 on visible light photocatalytic activity of two kinds of Ag2CO3/TiO2 prepared from different precursors. Appl. Catal. B: Environ 158, 224–232 (2014).

Li, J., Xie, Y., Zhong, Y. & Hu, Y. Facile synthesis of Z-scheme Ag2CO3/Ag/AgBr ternary heterostructured nanorods with improved photostability and photoactivity. J. Mater. Chem. A 3, 5474–5481 (2015).

Zhou, M. et al. WO3/Ag2CO3 mixed photocatalyst with enhanced photocatalytic activity for organic dye degradation. ACS Omega 6, 26439–26453 (2021).

Su, X. et al. Low-temperature synthesis one-dimensional Ag2CO3/SnFe2O4 Z -scheme with excellent visible-light photoactivity. J. Am. Ceram. Soc. 106, 3594–3604 (2023).

Heiba, Z. K. et al. Sonochemical synthesis of Ag2CO3/CeO2 p-n heterojunction for decomposition of rhodamine B dye. Opt. Mater. 141, 113945 (2023).

Perumal, K., Shanavas, S., Ahamad, T., Karthigeyan, A. & Murugakoothan, P. Construction of Ag2CO3/BiOBr/CdS ternary composite photocatalyst with improved visible-light photocatalytic activity on tetracycline molecule degradation. J. Environ. Sci. 125, 47–60 (2023).

Liu, J. et al. Selectively modulated photoresponse in type-i heterojunction for ultrasensitive self-powered photodetectors. Laser Photon. Rev. 16, 2200338 (2022).

Tan, C. et al. Broken-gap PtS2/WSe2 van der Waals heterojunction with ultrahigh reverse rectification and fast photoresponse. ACS Nano 15, 8328–8337 (2021).

Cai, H. et al. Orienting the charge transfer path of type-II heterojunction for photocatalytic hydrogen evolution. Appl. Catal. B: Environ. 256, 117853 (2019).

Liu, Z. et al. Construction of Z-scheme Ag/AgVO3/carbon-rich g-C3N4 heterojunction for enhanced photocatalytic degradation of sulfamethiadiazole: DFT calculation and mechanism study. Chem. Eng. J. 433, 133604 (2022).

Yuan, T. et al. P-doped bismuth sulfide for improved photocatalytic degradation of bisphenol A: Role of built-in electric field and S vacancies. J. Clean. Prod. 434, 140159 (2024).

Li, S. et al. Enhanced antibiotic degradation performance of Cd0.5Zn0.5S/Bi2MoO6 S-scheme photocatalyst by carbon dot modification. J. Mater. Sci. Technol. 164, 59–67 (2023).

Li, S., Cai, M., Wang, C. & Liu, Y. Ta3N5/CdS core-shell S-scheme heterojunction nanofibers for efficient photocatalytic removal of antibiotic tetracycline and Cr(VI): Performance and mechanism insights. Adv. Fiber Mater. 5, 994–1007 (2023).

Xu, Q., Zhang, L., Cheng, B., Fan, J. & Yu, J. S-scheme heterojunction photocatalyst. Chem 6, 1543–1559 (2020).

Zhao, X., Su, Y., Qi, X. & Han, X. A facile method to prepare novel Ag2O/Ag2CO3 three-dimensional hollow hierarchical structures and their water purification function. ACS Sustain. Chem. Eng. 5, 6148–6158 (2017).

Yin, S., Chen, Y., Li, M., Hu, Q. & Li, H. Construction of NH2-MIL-125(Ti)/Bi2WO6 composites with accelerated charge separation for degradation of organic contaminants under visible light irradiation. Green Energy Environ. 5, 203–213 (2020).

Zhang, S., Liu, Y., Liao, G., He, J. & Long, F. Nano particle/microsphere TiO2/BiOBr Z-scheme heterojunction with high visible-light photocatalytic activity in tetracycline hydrochloride degradation. J. Mater. Sci.: Mater. Electron. 33, 25878–25890 (2022).

Wang, J., Cheng, H., Wei, D. & Li, Z. Ultrasonic-assisted fabrication of Cs2AgBiBr6/Bi2WO6 S-scheme heterojunction for photocatalytic CO2 reduction under visible light. Chin. J. Catal. 43, 2606–2614 (2022).

Dong, K. et al. Integration of Plasmonic Effect and S-Scheme Heterojunction into Ag/Ag3PO4/C3N5 Photocatalyst for Boosted Photocatalytic Levofloxacin Degradation. Acta Physico-Chim. Sin. 40, 2310013 (2024).

Chen, Z. J. et al. Construction of dual S-scheme Ag2CO3/Bi4O5I2/g-C3N4 heterostructure photocatalyst with enhanced visible-light photocatalytic degradation for tetracycline. Chem. Eng. J. 438, 135471 (2022).

Li, X. et al. Preparation and characterization of Bi2O3-Bi2WO6 direct Z-scheme heterojunction and photocatalytic reduction of U(VI) under visible light irradiation. Acta Mater. Compos. Sin. 38, 2646–2654 (2021).

Zeng, H. et al. Ag2CO3@UiO-66-NH2 embedding graphene oxide sheets photocatalytic membrane for enhancing the removal performance of Cr(VI) and dyes based on filtration. Desalination 491, 114558 (2020).

Krivec, M. et al. The nature of chlorine-inhibition of photocatalytic degradation of dichloroacetic acid in a TiO2-based microreactor. Phys. Chem. Chem. Phys. 16, 14867 (2014).

Zhang, X., Zhang, Y., Wang, Z., Zhang, N. & Jia, X. Construction of a novel Ag2O/P-g-C3N4 p-n type heterojunction for efficient degradation of organic pollutants under visible light irradiation. Diamond Relat. Mater. 130, 109398 (2022).

Kaur, A. & Kansal, S. K. Bi2WO6 nanocuboids: An efficient visible light active photocatalyst for the degradation of levofloxacin drug in aqueous phase. Chem. Eng. J. 302, 194–203 (2016).

Gupta, G., Kaur, A., Sinha, A. S. K. & Kansal, S. K. Photocatalytic degradation of levofloxacin in aqueous phase using Ag/AgBr/BiOBr microplates under visible light. Mater. Res. Bull. 88, 148–155 (2017).

Hu, Z., He, Q. & Ge, M. Photocatalytic degradation of organic contaminants by magnetic Ag3PO4/MFe2O4 (M = Zn, Ni, Co) composites: A comparative study and a new insight into mechanism. J. Mater. Sci.: Mater. Electron. 32, 827–842 (2021).

Ali Al Hattali, O., Al Marzouqi, F., Al Mamari, S., Kuvarega, A. T. & Selvaraj, R. CdO nanoplates for photocatalytic degradation of Levofloxacin and nizatidine under natural solar light irradiation. Inorg. Chem. Commun. 146, 110071 (2022).

Zou, X., Wang, S., Wu, C., Peng, Z. & Yang, J. Bi-modified Bi2WO6/BiOI heterojunction with enhanced visible-light-driven photoactivity for antibiotic degradation. J. Nanomater. 2022, 1–18 (2022).

Shen, X. et al. Rationally designed S-scheme heterojunction of C3N4/Bi2MoO6/carbon fiber cloth as a recyclable, macroscopic and efficient photocatalyst for wastewater treatment. Chem. Eng. J. 445, 136703 (2022).

Li, S. et al. Chemically bonded Mn0.5Cd0.5S/BiOBr S-scheme photocatalyst with rich oxygen vacancies for improved photocatalytic decontamination performance. Adv. Powder Mater. 3, 100183 (2024).

Li, S., Dong, K., Cai, M., Li, X. & Chen, X. A plasmonic S-scheme Au/MIL-101(Fe)/BiOBr photocatalyst for efficient synchronous decontamination of Cr(VI) and norfloxacin antibiotic. eScience 4, 100208 (2024).

Shen, X. et al. Magnetically recyclable and remarkably efficient visible-light-driven photocatalytic hexavalent chromium removal based on plasmonic biochar/bismuth/ferroferric oxide heterojunction. J. Colloid Interface Sci. 590, 424–435 (2021).

Author information

Authors and Affiliations

Contributions

P. T. and H. B. designed and supervised the experiments. J. L. and Q. Y. conducted the experiments. Q. Y. helped in providing the various tests. J. L. wrote the manuscript. Y. C., C. G., H. Z. and J. L. revised the manuscript. All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, J., Tu, P., Yang, Q. et al. A novel type-II–II heterojunction for photocatalytic degradation of LEV based on the built-in electric field: carrier transfer mechanism and DFT calculation. Sci Rep 14, 10643 (2024). https://doi.org/10.1038/s41598-024-60250-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-60250-z

Keywords

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.