Abstract

The most general frictional motion in nature involves bimaterial interfaces, when contacting bodies possess different elastic properties. Frictional motion occurs when the contacts composing the interface separating these bodies detach via propagating rupture fronts. Coupling between slip and normal stress variations is unique to bimaterial interfaces. Here we use high speed simultaneous measurements of slip velocities, real contact area and stresses to explicitly reveal this bimaterial coupling and its role in determining different classes of rupture modes and their structures. We directly observe slip-pulses, highly localized slip accompanied by large local reduction of the normal stress near the rupture tip. These pulses propagate in the direction of motion of the softer material at a selected (maximal) velocity and continuously evolve while propagating. In the opposite direction bimaterial coupling favors crack-like ‘supershear’ fronts. The robustness of these structures shows the importance of bimaterial coupling to frictional motion and modes of frictional dissipation.

Similar content being viewed by others

Introduction

Most studies of frictional sliding have considered homogeneous systems involving sliding bodies composed of the same material1,2,3,4. Within homogenous interfaces, the rupture fronts that generally mediate the onset of friction are closely related to classic shear cracks3, which are characterized by near-tip singularity and extended slip duration. Spatially localized slip, pulse-like ruptures, may also occur along homogenous interfaces5,6,7,8, but are generally associated with the form of the friction law; occurring when frictional resistance is markedly reduced near a rupture tip. Examples include extreme velocity weakening5,9 or flash heating9.

The existence of a bimaterial interface can bring about qualitative differences in how contact points detach5,8,10,11,12,13,14,15,16,17,18,19,20,21. In homogenous systems, due to the symmetry of the system, stress-field components of both crack-like and pulse-like ruptures are either symmetric (Δσij(−y)=Δσij(y)) or anti-symmetric (Δσij(−y)=−Δσij (y)). In contrast, any slip within a bimaterial interface will break the stress symmetry across the interface. One important result of this is that local values of normal stress variations at the interface are theoretically expected to couple to interface slip. This ‘bimaterial coupling’ is an elastodynamic coupling and is independent of specific properties of the friction law at the interface. Bimaterial coupling is strongest at the rupture tip, where stresses are maximal, and intensifies strongly with both the ratio of sound wave velocities10,13 of the contacting materials (‘material contrast’)5,13 and with the rupture front velocity10,19, Cf. The sign of the coupling depends on the front propagation direction. Ruptures propagating in the direction of motion of the more compliant material, which we will call the ‘positive’ direction, can radically decrease the normal stress10,12,19, σyy, near the rupture tip. Therefore, in the positive direction, frictional resistance locally decreases, enhancing slip. Frictional resistance may theoretically vanish as Cf (t) approaches its limiting velocity, the generalized Rayleigh wave speed, CGR, for low material contrasts and the shear wave velocity of the compliant material,  , for higher material contrasts (Methods). This elastodynamic reduction in σyy is predicted to lead to distinct slip-pulses10,12 characterized by slip that is strongly localized around rupture tips and driven by highly localized reduction of σyy. In the opposite ‘negative’ direction, where motion of the compliant material is opposite the rupture direction, the sign of the coupling is reversed for sub-sonic (Cf<

, for higher material contrasts (Methods). This elastodynamic reduction in σyy is predicted to lead to distinct slip-pulses10,12 characterized by slip that is strongly localized around rupture tips and driven by highly localized reduction of σyy. In the opposite ‘negative’ direction, where motion of the compliant material is opposite the rupture direction, the sign of the coupling is reversed for sub-sonic (Cf< ) ruptures8,17 and σyy near rupture tips increases. Only for ‘supershear’ ruptures (Cf>

) ruptures8,17 and σyy near rupture tips increases. Only for ‘supershear’ ruptures (Cf> ) does bimaterial coupling enhance slip when ruptures propagate in the negative direction8,17,18,21. The limiting velocity in the negative direction is therefore predicted to be slightly below the P-wave velocity of the softer material8,17,21,

) does bimaterial coupling enhance slip when ruptures propagate in the negative direction8,17,18,21. The limiting velocity in the negative direction is therefore predicted to be slightly below the P-wave velocity of the softer material8,17,21,  .

.

Relatively few experiments have focused on bimaterial frictional rupture6,7,22,23. Experiments using low material contrast7,23 observed strong directionality; ruptures in the positive direction were limited by CGR, whereas in the negative direction sub-shear ruptures were seen to transition to supershear. Follow-up experiments22 also observed transitions to the fast  in the positive direction. In systems with strong material contrast, single-point particle velocity and normal displacement measurements provided evidence for transient opening6. These experiments, however, measured continuous spatially extended sliding similar to rupture of homogeneous interfaces in the same set-up7,17,23, in apparent contradiction to claims of pulse-like ruptures. This apparent confusion may be due to the explosive triggering used in all of the above experiments (point explosions or projectile impact), whose effect on rupture mode selection is not fully understood17. No direct measurements of the stress fields driving rupture exist.

in the positive direction. In systems with strong material contrast, single-point particle velocity and normal displacement measurements provided evidence for transient opening6. These experiments, however, measured continuous spatially extended sliding similar to rupture of homogeneous interfaces in the same set-up7,17,23, in apparent contradiction to claims of pulse-like ruptures. This apparent confusion may be due to the explosive triggering used in all of the above experiments (point explosions or projectile impact), whose effect on rupture mode selection is not fully understood17. No direct measurements of the stress fields driving rupture exist.

Many aspects of bimaterial-induced ruptures are controversial; questions of slip-pulse stability8,15,19,20,21,24, mode and velocity selection7,8,12,16,17,25 and the possibility of separation at the interface7,12,15,19,21 abound. As both slip-pulses and crack-like modes may coexist along bimaterial interfaces6,12,17,25, which of these dominates is an important open question8.

Here we study spontaneously nucleated slip along bimaterial interfaces under quasi-static loading, measuring the real contact area and full strain tensor near the interface at high speeds. These measurements explicitly demonstrate the unique effects of bimaterial coupling and reveal structures that are characteristic only to this coupling; slip-pulses propagating exclusively at  in the positive direction and solely crack-like propagation in the negative one that are dominated by supershear modes.

in the positive direction and solely crack-like propagation in the negative one that are dominated by supershear modes.

Results

Experimental system

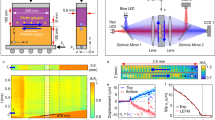

Our experimental system consists of both homogeneous and bimaterial interfaces composed of, respectively, two PMMA (polymethylmethacrylate) blocks or polycarbonate (PC) sliding on PMMA (Fig. 1a). The material wave velocities are:  =1,345±10 ms−1,

=1,345±10 ms−1,  =2,330±10 ms−1,

=2,330±10 ms−1,  =932±20 ms−1 and

=932±20 ms−1 and  =1,690±20 ms−1, providing a ∼40% material contrast.

=1,690±20 ms−1, providing a ∼40% material contrast.  =

= is the expected limiting velocity in the positive direction. Both blocks are first compressed with a normal force, 2,000<FN<6,000 N. Slip is triggered quasi-statically either by increasing the shear force FS at fixed FN or, alternatively, by fixing FS and reducing FN (Methods). The applied values of FS and FN had no significant effect on our results. Throughout the experiments, we performed continuous optical measurements of the real contact area, A(x,t), along the entire interface with (x × z) spatial resolution 1,280 × 8 pixels at 580,000 frames per second. A(x,t) (averaged over z) are normalized relative to A0(x), defined as A(x) at ∼10 ms before rupture onset. The rupture front location, xtip, is defined as the point where A(xtip)=0.95·A0(x). Cf (t) was obtained from xtip(t). Simultaneous measurements of the strain tensor, ɛij(t) were performed at 20 locations along and ≈2 mm above and beneath the interface with each strain component measured at 106 samples per second. For rupture fronts propagating with constant velocity ɛij(x,t)=ɛij(x−Cft). Using this3, we converted ɛij(t) to spatial measurements ɛij(x−xtip), stresses σij(x−xtip) (plane stress conditions), and particle velocities

is the expected limiting velocity in the positive direction. Both blocks are first compressed with a normal force, 2,000<FN<6,000 N. Slip is triggered quasi-statically either by increasing the shear force FS at fixed FN or, alternatively, by fixing FS and reducing FN (Methods). The applied values of FS and FN had no significant effect on our results. Throughout the experiments, we performed continuous optical measurements of the real contact area, A(x,t), along the entire interface with (x × z) spatial resolution 1,280 × 8 pixels at 580,000 frames per second. A(x,t) (averaged over z) are normalized relative to A0(x), defined as A(x) at ∼10 ms before rupture onset. The rupture front location, xtip, is defined as the point where A(xtip)=0.95·A0(x). Cf (t) was obtained from xtip(t). Simultaneous measurements of the strain tensor, ɛij(t) were performed at 20 locations along and ≈2 mm above and beneath the interface with each strain component measured at 106 samples per second. For rupture fronts propagating with constant velocity ɛij(x,t)=ɛij(x−Cft). Using this3, we converted ɛij(t) to spatial measurements ɛij(x−xtip), stresses σij(x−xtip) (plane stress conditions), and particle velocities  =−ΔɛxxCf (u is the displacement field). Ruptures in the positive (negative) direction will be presented as propagating from left to right (right to left), as defined in Fig. 1a.

=−ΔɛxxCf (u is the displacement field). Ruptures in the positive (negative) direction will be presented as propagating from left to right (right to left), as defined in Fig. 1a.

(a) Twenty rosette strain gauges (green squares) are mounted ≈2 mm above and beneath the frictional interface (left), on opposing block faces (centre). Green (purple) arrows define positive (negative) rupture propagation directions as parallel (anti-parallel) to the direction of the motion of the compliant material. (b) The real contact area, A(x,t) (normalized before nucleation at t=0), along the 200 mm quasi-1D interface. Insets: magnified sections of A(x,t). (c) A(x−xtip) measured around rupture tip locations, xtip, denoted in a; (black) PMMA on PMMA (homogenous system), Cf=0.94CR, FN=3,402 N, (green) Polycarbonate (PC) on PMMA (bimaterial system) for rupture in the positive direction, Cf=0.99CSsoft, FN=3,863 N, and (purple) leftward supershear rupture in the negative direction, Cf=0.92CLsoft, FN=3,553 N. Negative direction propagation was reversed for comparison.

Contact area profiles

Figure 1b compares real contact area, A(x,t), measurements of typical ruptures propagating near their theoretical asymptotic velocities; the Rayleigh wave velocity, CR, for homogenous systems,  for bimaterial fronts in the positive direction, and supershear velocities approaching

for bimaterial fronts in the positive direction, and supershear velocities approaching  in the negative direction. Figure 1c presents corresponding typical contact area profiles A(x−xtip) at specific times, t0.

in the negative direction. Figure 1c presents corresponding typical contact area profiles A(x−xtip) at specific times, t0.

A(x,t) is a quantity that reflects the instantaneous interface strength and is determined by both σyy(x,t) and the age of the contacts. During rupture front propagation, contacts are broken at the rupture tip and reform once the front passes. Along homogenous interfaces, A(x−xtip) drops like a step function from A0(x) to instantaneous residual values of 0.6−0.8A0(x) that result from the fractured/broken contacts. Residual values remain constant for the duration of a slip event, which is shorter than the logarithmic aging time2 needed to restore A0(x).

Along the positive direction in bimaterial systems, A(x,t) have much richer dynamics of contact formation and separation. Before rupture arrival, A(x) increases by 15–30%, suggesting an initial compression. As the rupture tip passes, A(x) can drop to as low as 0.03A0(x). In contrast to homogeneous systems, within a few mm’s from xtip, this large drop in A(x) is followed by a rapid (dynamic) increase to residual values of 0.7–0.9A0(x) (0.9A0(x) in Fig. 1b. This re-strengthening takes place over times ≈10 μs which are orders of magnitude less than the aging recovery time in homogeneous systems2. For supershear fronts along the negative direction in the bimaterial system, A(x) drop like step functions to 0.6–0.8A0(x), with slight transient variations of A(x) reminiscent of the strong bimaterial effect in the positive direction.

The unique behaviour of A(x,t) in the positive direction suggests that the rapid variations of A(x) echo local variations of σyy(x,t) as predicted5,8,10,12,13,17. These strong correlations are explicitly presented in Fig. 2, where we compare direct measurements of A(x,t), σyy and  surrounding the rupture tip. As we measure 2 mm from the interface, the magnitudes of

surrounding the rupture tip. As we measure 2 mm from the interface, the magnitudes of  and Δσyy are lower bounds of their values on the interface. For singular fronts these should significantly exceed those of Fig. 2.

and Δσyy are lower bounds of their values on the interface. For singular fronts these should significantly exceed those of Fig. 2.

Comparisons of contact area, A(x,t) (a,d,g), normal stresses, σyy(t) (b,e,h), and particle velocities,  , (c,f,i) for the ruptures presented in Fig. 1b. Signs of

, (c,f,i) for the ruptures presented in Fig. 1b. Signs of  correspond to the motion directions denoted in Fig. 1a. Line colours represent measurements within the different blocks: red lines denote measurements within the stiff material (PMMA) and blue measurements within the compliant material (PC). (a–c) Homogenous interface, xtip=109 mm: (red dashed line) top block, (solid line) bottom block. Bimaterial interfaces, (d–f) positive direction, xtip=125 mm and (g–i) negative direction, xtip=87 mm. Ruptures along the positive direction are characterized by highly localized signals compared with those in the homogenous and negative directions. Insets in c,f and i:

correspond to the motion directions denoted in Fig. 1a. Line colours represent measurements within the different blocks: red lines denote measurements within the stiff material (PMMA) and blue measurements within the compliant material (PC). (a–c) Homogenous interface, xtip=109 mm: (red dashed line) top block, (solid line) bottom block. Bimaterial interfaces, (d–f) positive direction, xtip=125 mm and (g–i) negative direction, xtip=87 mm. Ruptures along the positive direction are characterized by highly localized signals compared with those in the homogenous and negative directions. Insets in c,f and i:  measurements for −60<x−xtip<0 demonstrate slip localization solely in the positive direction. Line colours in d and g correspond to the rupture propagation directions denoted in Fig. 1.

measurements for −60<x−xtip<0 demonstrate slip localization solely in the positive direction. Line colours in d and g correspond to the rupture propagation directions denoted in Fig. 1.

Comparison of characteristic structures

We first consider the homogeneous system in Fig. 2a–c where σyy and  correspond to (shear) crack-like (extended slip) ruptures3. Normal stress variations from the initial value, Δσyy, are clearly anti-symmetric. This is consistent with Δσyy=0 at the interface with the drop in A(x,t) solely due to fractured contacts. As expected for shear cracks,

correspond to (shear) crack-like (extended slip) ruptures3. Normal stress variations from the initial value, Δσyy, are clearly anti-symmetric. This is consistent with Δσyy=0 at the interface with the drop in A(x,t) solely due to fractured contacts. As expected for shear cracks,  have long tails beyond the rupture tip (Fig. 2c inset) and increase with both Cf and FN (ref. 26).

have long tails beyond the rupture tip (Fig. 2c inset) and increase with both Cf and FN (ref. 26).

We now turn to bimaterial ruptures in the positive direction (Fig. 2d–f). Δσyy and  are highly asymmetric in both their structure and amplitude. As Δσyy in the stiffer material have much larger amplitudes than in softer material, we consider this signal as representative of the normal stress variations at the interface. As the front approaches, σyy undergoes compression corresponding to the increase of A(x) before rupture. Both σyy and A(x) at the rupture tip evolve with the distance from the rupture tip. At the rupture tip the reduction in both of these quantities is extreme and both can approach zero. The reductions of σyy and A are highly localized in space and time compared with the homogenous system. Within ∼10 μs (∼10 mm) after the rupture tip passes, σyy is dynamically restored to its initial value. Similar behaviour is exhibited by A(x−xtip), although the recovery of A(x−xtip) is incomplete due to broken/separated contacts2. In the same ∼10 μs interval, all of the slip takes place;

are highly asymmetric in both their structure and amplitude. As Δσyy in the stiffer material have much larger amplitudes than in softer material, we consider this signal as representative of the normal stress variations at the interface. As the front approaches, σyy undergoes compression corresponding to the increase of A(x) before rupture. Both σyy and A(x) at the rupture tip evolve with the distance from the rupture tip. At the rupture tip the reduction in both of these quantities is extreme and both can approach zero. The reductions of σyy and A are highly localized in space and time compared with the homogenous system. Within ∼10 μs (∼10 mm) after the rupture tip passes, σyy is dynamically restored to its initial value. Similar behaviour is exhibited by A(x−xtip), although the recovery of A(x−xtip) is incomplete due to broken/separated contacts2. In the same ∼10 μs interval, all of the slip takes place;  is dominant and large (can surpass 2 ms−1), highly peaked immediately following the rupture tip and

is dominant and large (can surpass 2 ms−1), highly peaked immediately following the rupture tip and  → 0 once σyy is dynamically restored.

→ 0 once σyy is dynamically restored.

When considered together, the structures, magnitudes and symmetries of Δσyy and  provide clear evidence for the coupling between slip and σyy unique to bimaterial interfaces. The large variations over such short durations reveal that propagation in the positive direction is governed by slip-pulses driven by strong bimaterial coupling. In the negative direction, Δσyy and

provide clear evidence for the coupling between slip and σyy unique to bimaterial interfaces. The large variations over such short durations reveal that propagation in the positive direction is governed by slip-pulses driven by strong bimaterial coupling. In the negative direction, Δσyy and  are not localized in space and slowly decrease (Fig. 2i inset) after attaining peak values. Δσyy are an order of magnitude smaller than in the positive direction. While both Δσyy and

are not localized in space and slowly decrease (Fig. 2i inset) after attaining peak values. Δσyy are an order of magnitude smaller than in the positive direction. While both Δσyy and  possess pronounced asymmetry, bimaterial supershear ruptures are not pulse-like but, instead, involve crack-like propagation in the negative direction.

possess pronounced asymmetry, bimaterial supershear ruptures are not pulse-like but, instead, involve crack-like propagation in the negative direction.

Slip-pulse evolution and velocity selection

Figure 3a displays the typical evolution of A(x,t) for a propagating slip-pulse. The slip-pulses continuously evolve; we have never observed steady-state propagation in the positive direction. Figure 3b shows that the magnitudes of both  and the variations of A(x,t) increase significantly with propagation distance. In addition, as a slip-pulse evolves, its pulse width, both in

and the variations of A(x,t) increase significantly with propagation distance. In addition, as a slip-pulse evolves, its pulse width, both in  and A(x,t), can more than double (Fig. 3d) with propagation distance. Figure 3d demonstrates the rough proportionality of the widths of the particle velocity, δv, and contact area, δA (Fig. 3c), over a wide range of loading and nucleation conditions. Deviations from proportionality for narrow pulses may result from our finite (∼1 μs) temporal resolution. δA always precedes δv. This consistent phase shift may either be a characteristic feature of slip-pulses or may result from the fact that δv is measured 2 mm above the interface while δA is measured on the interface.

and A(x,t), can more than double (Fig. 3d) with propagation distance. Figure 3d demonstrates the rough proportionality of the widths of the particle velocity, δv, and contact area, δA (Fig. 3c), over a wide range of loading and nucleation conditions. Deviations from proportionality for narrow pulses may result from our finite (∼1 μs) temporal resolution. δA always precedes δv. This consistent phase shift may either be a characteristic feature of slip-pulses or may result from the fact that δv is measured 2 mm above the interface while δA is measured on the interface.

(a) A(x,t) of a typical front in the positive direction. Right panels are close-ups of A(x,t) in the marked areas. Red arrows denote secondary and tertiary slip-pulses that follow the main slip-pulse which are absent during the earlier (55–75 mm) propagation. (b)  (x) (top) and A(x) (bottom) profiles along the interface. Each profile is displayed around xtip locations coinciding with the strain gauge locations (coloured lines) denoted in a. (c) Close-ups of

(x) (top) and A(x) (bottom) profiles along the interface. Each profile is displayed around xtip locations coinciding with the strain gauge locations (coloured lines) denoted in a. (c) Close-ups of  (x−xtip) (top) and A(x−xtip) (bottom) for xtip=165 mm. We define pulse widths; δv is defined from the point where

(x−xtip) (top) and A(x−xtip) (bottom) for xtip=165 mm. We define pulse widths; δv is defined from the point where  becomes positive (circle), to 2/3 of the difference between maximal and residual values (Methods). δA is defined from the point of maximal compression of A(x−xtip) (circle) to 1/3 of the difference between its residual and minimal values. (d) δA versus δv for 131 fronts for 2,000<FN<6,000 N. Colours: locations denoted in a.

becomes positive (circle), to 2/3 of the difference between maximal and residual values (Methods). δA is defined from the point of maximal compression of A(x−xtip) (circle) to 1/3 of the difference between its residual and minimal values. (d) δA versus δv for 131 fronts for 2,000<FN<6,000 N. Colours: locations denoted in a.

A characteristic feature of the observed slip-pulses is the appearance of evolving secondary pulses that follow the main rupture. Secondary pulse appearance is highlighted in Fig. 3a. Secondary pulses are responsible for the fine structure evident in both in  and A(x,t) in Fig. 3b,c and can reach half of the main pulse amplitude.

and A(x,t) in Fig. 3b,c and can reach half of the main pulse amplitude.

The results of Fig. 3 suggest that no real slip-pulse stability may exist;  , σyy and A(x,t) constantly evolve with propagation distance. This evolution could be due to the asymptotic approach of Cf to

, σyy and A(x,t) constantly evolve with propagation distance. This evolution could be due to the asymptotic approach of Cf to  in the positive direction or, alternatively, result from an intrinsic lack of stability of this mode. Such an instability, known as the Adam’s instability13,21,24 has been predicted; slip-pulses are expected to sharpen12,17,24 and eventually break up with evolution12,19. This may also explain the nucleation of the secondary pulses observed here.

in the positive direction or, alternatively, result from an intrinsic lack of stability of this mode. Such an instability, known as the Adam’s instability13,21,24 has been predicted; slip-pulses are expected to sharpen12,17,24 and eventually break up with evolution12,19. This may also explain the nucleation of the secondary pulses observed here.

Figure 4 unambiguously shows that rupture velocity distributions in opposite propagation directions are entirely different, as both predictions8,10,12,13,17,21 and previous experiments22,23 have suggested. In the positive direction, nearly all ruptures have a sharp well-defined velocity, Cf= . In this direction supershear fronts, over a wide range of velocities, are rarely observed. All of these nucleate only as secondary ruptures ahead of the concurrently propagating main rupture at

. In this direction supershear fronts, over a wide range of velocities, are rarely observed. All of these nucleate only as secondary ruptures ahead of the concurrently propagating main rupture at  .

.

(a) Histogram of 213 steadily propagating (Methods) ruptures in the positive direction for various experimental loading conditions and 2,000<FN<6,000 N. (b) Histogram of 98 steadily propagating ruptures in the negative direction, conditions as in a. Green and red lines denote, respectively, CLsoft and CSsoft. Note the sharp selection (88% of all primary ruptures) at CSsoft in the positive direction whereas CSsoft is never observed in the negative one.

In the negative direction supershear fronts dominate propagation. Their velocities are concentrated near Cf=0.91 . They nucleate directly, without being preceded by a well-defined stage of sub-Rayleigh rupture. The distinction between the smooth transition to supershear in the negative direction and the transition as a secondary nucleation in the positive direction is consistent with recent simulations27 that considered bimaterial coupling. In the negative direction we sometimes observe ruptures at sub-Rayleigh velocities. Their structure appears similar to homogeneous crack-like ruptures and, significantly, Cf never approaches

. They nucleate directly, without being preceded by a well-defined stage of sub-Rayleigh rupture. The distinction between the smooth transition to supershear in the negative direction and the transition as a secondary nucleation in the positive direction is consistent with recent simulations27 that considered bimaterial coupling. In the negative direction we sometimes observe ruptures at sub-Rayleigh velocities. Their structure appears similar to homogeneous crack-like ruptures and, significantly, Cf never approaches  in the negative direction.

in the negative direction.

The rupture velocity values and asymmetric distributions in the different directions (Fig. 4) provide further evidence for strong bimaterial coupling. Particularly telling observations are the sharp selection in the positive direction at Cf= with near-total disappearance of lower sub-shear velocities and the observation that Cf never approaches

with near-total disappearance of lower sub-shear velocities and the observation that Cf never approaches  in the negative one. These are theoretically expected results13; in the positive direction bimaterial coupling is maximal at

in the negative one. These are theoretically expected results13; in the positive direction bimaterial coupling is maximal at  when σyy approaches (Fig. 2e) near-zero values, whereas increased σyy at the tip is expected when propagating in the negative direction.

when σyy approaches (Fig. 2e) near-zero values, whereas increased σyy at the tip is expected when propagating in the negative direction.

Discussion

The unique structures and features that characterize ruptures along bimaterial interfaces in our experiments indicate a clear dichotomy of the dominant propagation modes along bimaterial interfaces; unambiguous slip-pulses with a single sharply selected velocity in the positive direction and supershear ruptures with crack-like features in the negative one. These observations establish the importance of bimaterial coupling in driving interface dynamics. We have explicitly shown that  , A(x,t) and σyy strongly couple to produce these diverse structures, as predicted by bimaterial coupling with no need to invoke effects due to friction laws.

, A(x,t) and σyy strongly couple to produce these diverse structures, as predicted by bimaterial coupling with no need to invoke effects due to friction laws.

Due to the inherent generality of bimaterial interfaces, we expect that these results may have important implications for our fundamental understanding of the onset of frictional motion and where and how frictional dissipation occurs. The properties of bimaterial ruptures are of particular interest in earthquake dynamics28. While it is clear that natural faults are considerably more complex than the ‘simple’ frictional interfaces studied here, the general nature of the features described above leads us to expect them to persist in faults bounded by different rock types. For example, the detailed structure of the stress fields described in our results supports observations of the coupling between earthquake directionality and off-fault damage29.

Methods

System and material properties

Our experiments were conducted using two sets of blocks. For the homogenous interface we used two poly(methylmethacrylate) (PMMA) blocks of dimensions 220 × 100 × 5.5 mm (top block) and 200 × 100 × 5.5 mm (bottom block) in the x, y and z direction, respectively (Fig. 1a). For the bimaterial interface we used a polycarbonate (PC) block of dimensions 197 × 100 × 5.8 mm sliding on the 220 × 100 × 5.5 mm PMMA block. The contact faces of the blocks were diamond-machined to optical flatness.

Material shear, CS, and longitudinal, CL, wave speeds were obtained by measuring the time of flight of 5 MHz ultrasonic pulses, yielding  =1,345±10 ms−1,

=1,345±10 ms−1,  =2,700±10 ms−1,

=2,700±10 ms−1,  =932±20 ms−1 and

=932±20 ms−1 and  =2,220±20 ms−1. Due to the small wavelength of the ultrasonic pulses used compared with the dimensions of the measurement set-up, the measured CL correspond to plane strain conditions (ɛzz=0). The small z dimension of the experimental set-up implies plane stress (σzz=0) conditions in our experiments. Using the above measured velocities, CL for plane stress were calculated to be

=2,220±20 ms−1. Due to the small wavelength of the ultrasonic pulses used compared with the dimensions of the measurement set-up, the measured CL correspond to plane strain conditions (ɛzz=0). The small z dimension of the experimental set-up implies plane stress (σzz=0) conditions in our experiments. Using the above measured velocities, CL for plane stress were calculated to be  =2,330±10 ms−1 and

=2,330±10 ms−1 and  =1,690±20 ms−1. The corresponding Rayleigh wave speed of the homogenous system is:

=1,690±20 ms−1. The corresponding Rayleigh wave speed of the homogenous system is:  =1,237±10 ms−1. The generalized Rayleigh wave speed, CGR, of a bimaterial interface is the speed where a disturbance, confined to the interface region, will propagate with no attenuation. CGR is not defined for all values of the material contrast5,10,21. This is the case for the PMMA–PC system. In such cases, the limiting velocity in the preferred direction is predicted to be the slower shear wave velocity,

=1,237±10 ms−1. The generalized Rayleigh wave speed, CGR, of a bimaterial interface is the speed where a disturbance, confined to the interface region, will propagate with no attenuation. CGR is not defined for all values of the material contrast5,10,21. This is the case for the PMMA–PC system. In such cases, the limiting velocity in the preferred direction is predicted to be the slower shear wave velocity,  =

= .

.

The wave speeds and the mass density, ρPMMA=1,170 kg m−3 and ρPC=1,200 kg m−3, and the wave speed measurements yield dynamic values for the Poisson ratio of νPMMA=0.33 and νPC=0.39 and Young’s moduli of  =5.6 GPa and

=5.6 GPa and  =2.9 GPa. Note that the values of E are significantly different from the static values

=2.9 GPa. Note that the values of E are significantly different from the static values  =3 GPa and

=3 GPa and  =2.4 GPa. This difference is due to viscoelastic behaviours of PMMA30 and PC.

=2.4 GPa. This difference is due to viscoelastic behaviours of PMMA30 and PC.

Loading application

In the experimental system, the top block was clamped at its top edge, while the bottom block was rigidly mounted at its bottom edge in a stiff low-friction linear translational stage. Both blocks were first compressed with a normal force which was varied between experiments throughout the range 2,000<FN<6,000 N (∼2<σyy<5 MPa). External shear loads, FS, were then applied to the stiff translational stage which was constrained in its movement only by the frictional resistance at the interface with the top block. In this way, FS was spatially distributed along the entire length of the interface. Both FN and FS were continuously monitored throughout the experiment by means of S-Beam load cells (of stiffness 106–107 N m−1) in series with the loading apparatus. An optional rigid stopper of cross-section 1 cm2 could be applied to the top block at x=0 mm, at a controllable height h, to constrain motion of this edge in the x direction and control torqueing. The application of the stopper thus introduced some elements of edge loading.

To explore a range of external loading conditions, the experiments were conducted using two distinct ways to trigger rupture nucleation: (1) FS were applied to the system quasi-statically, at fixed FN, at loading rates between 4 and 15 N s−1 until slip initiated. With this triggering method, the ruptures were usually nucleated along the quarter of the interface close to x=0 mm, either as a result of the edge loading or reduced local normal force resulting from induced torques. (2) At the completion of a sequence of slip events, the residual FS was kept fixed, and FN was reduced at loading rates between 40 and 60 N s−1, resulting in spontaneous rupture nucleation. The last triggering method yielded a wider distribution of nucleation locations along the interface.

For both triggering methods, ruptures would simultaneously nucleate in both directions. The rupture propagation mode (positive or negative) of the longest rupture could be controlled by vertically inverting the compliant and stiff blocks. Our choice of whether the compliant (stiff) block was mounted on the top or bottom produced, as expected, no overall difference in our results. We note that while rupture events occurred while either FS or FN were modified, the changes in FS or FN were sufficiently slow so that their values were constant during the (100–200 μs) rupture propagation period.

Real contact area measurements

Changes in the real contact area along the entire interface were measured by an optical method based on total internal reflection. Basic principles are presented in detail elsewhere3,31,32. A sheet of light, incident on the frictional interface at an angle well beyond the critical angle for total internal reflection, is reflected everywhere except at the contact points. This yields an instantaneous transmitted light intensity that is roughly proportional to A(x,z,t) over the entire (x × z) 200 × 5.5 mm interface. The transmitted light is continuously imaged (at a spatial resolution of 1,280 × 8 pixels) at 580,000 frames per second using a high speed camera, Phantom v711 at 12 bit accuracy. Data acquisition is continuous. The data are temporarily stored in a circular buffer large enough to acquire 7–13 ms of data, both before and after each event. The frictional interface is quasi-one-dimensional (1D), as its width (z direction), 5.5 mm, is much smaller than other dimensions of the block. The simultaneous measurements of A(x,t)=<A(x,z,t)>z along the entire 1D interface are obtained by averaging of the acquired images over the 8 pixels in the z direction. We use a high power LED (CBT-120) as our illumination source of noncoherent light (Methods in Svetlizky & Fineberg3). The noise level after integration is ≤1% of the signal.

When the contact area at a point drops to only few per cent of its initial value (during a slip event when the rupture propagates in the preferred direction) the transmitted light is comparable to the background (due to scattered light at the interface). As a result, the values of contact area measurements quoted in the paper are maximal values. This implies that the two faces may actually (temporarily) completely detach from one another—that is, the interface may indeed separate within a slip-pulse in the preferred direction.

Rupture front velocity Cf calculation

The rupture front location, xtip, is defined as the point where A(xtip)=0.95·A0(x). Cf(t) is obtained from xtip(t). Our precision in determining in Cf(t) depends on our 200 μm uncertainty in x. We consider ‘instantaneous’ values of Cf(t) as velocity values determined over 10 mm intervals. For these values of Cf(t) our resolution varies between 1 and 2%.

We define steadily propagating ruptures with velocity Cf as ruptures having no clear tendency to accelerate or decelerate. Within these intervals instantaneous measurements of Cf(t) change by <30 ms−1 while traversing distances of at least 50 mm. This is ≤ 1–3% of the velocity for the supershear and  fronts presented in this study.

fronts presented in this study.

Strain measurements

We use miniature Kulite B/UGP-1000-060-R3 rosette strain gauges for local strain measurements. Twenty such strain gauges are mounted along and ∼2 mm above and beneath the frictional interface, on opposing block faces (Fig. 1a). Each rosette strain gauge is composed of three independent active regions (each 0.4 × 0.9 mm in size)—two of these are oriented at ±45° relative to the third, which is oriented normal to the interface. The individual gauges are separated by 0.55 mm in the x direction. During rapid rupture propagation, this distance induces a small time delay ∼0.55/Cf ∼0.5 μs between the components. This was taken into account for the proper calculation of ɛij(t). The strain gauges have a slightly non-linear gauge factor response of ΔR/R=4,689ɛ2+110.1ɛ, which was also taken into account. All strain signals (60 channels) are amplified (gain=11, ∼1 MHz bandwidth) and simultaneously acquired to 14 bit accuracy by an ACQ132 digitizer (D-tAcq Solutions Ltd) at a 1 MHz rate. This leads to a sensitivity of ∼2μStrain in ɛij(t) measurements. As the signals are of order ∼1mStrain this provides a 0.2% uncertainty in ɛij.

As shown in Fig. 1a, the strain gauges were mounted on opposing faces of the two blocks (that is, at points [x,y,z]=[x,+2 mm,0] and [x,−2 mm, 5.5 mm]). Measured dynamic values (rapid variations) of σxy (t) on both sides of the interface, (σxy is the only continuous quantity expected across the interface) were in good agreement with <5–10% error. As a result, all dynamic measurements of ɛij (t) reliably reflect the dynamic 1D signal along the interface.

The small differences in the block widths (<0.5 mm) and experimental alignment limitations, at times, resulted in discrepancies in static values of ɛij (t<0) that were measured along opposing sides of the interface. We found that, despite these discrepancies, the average of opposing strain gauges agreed well with the mean value of the normal stress along the interface, as determined by dividing the applied normal force, FN, by the interface area. The last was used as the static value in the calculation of normal stress variations Δσyy(t)=σyy(t)−σyy(t<0) in the text.

As our evaluation of σyy(t) and the slip velocity is done via strain gauges located 2 mm from the interface, our measurements only provide us with an estimate of these values on the interface. In the paper, we considered only the dominant signal in the two blocks; the softer material’s (PC) signal for  and the stiffer material’s (PMMA) for σyy. Estimates of these signals on the interface (for example, by averaging the two signals) only slightly alters their maximal amplitudes. Summing opposing signals was not performed when we considered stress or strain variations, however, because any uncertainty in the x location of opposing strain gauges (due to slip throughout an experiment) could bring about phase differences in opposing signals. Since these signals are rapidly varying quantities, any uncertainty in their relative phase could have induced large measurement errors.

and the stiffer material’s (PMMA) for σyy. Estimates of these signals on the interface (for example, by averaging the two signals) only slightly alters their maximal amplitudes. Summing opposing signals was not performed when we considered stress or strain variations, however, because any uncertainty in the x location of opposing strain gauges (due to slip throughout an experiment) could bring about phase differences in opposing signals. Since these signals are rapidly varying quantities, any uncertainty in their relative phase could have induced large measurement errors.

For steadily moving rupture fronts ɛij(x,t)=ɛij(x−Cft). Using this, we converted ɛij(t) to spatial measurements ɛij(x−xtip) (Methods in Svetlizky & Fineberg3), stresses, σij(x−xtip) (assuming plane stress conditions) and particle velocities  (t)=−ɛxx(t)˙Cf(t).

(t)=−ɛxx(t)˙Cf(t).

Determination of pulse widths δv and δA

We defined the widths of the slip velocity and contact area pulses by, respectively, δv and δA, as follows (Fig. 4c). Slip initiation is identified with the point when the velocity becomes positive as a rupture passes. To avoid effects of secondary pulses (see inset Fig. 4a) on the determination of these widths, we defined the end of the δv when the slip velocity relaxed to two thirds of the difference between the maximal  and its final residual value. Final residual values were defined as the average value in the range of 20–25 mm behind the rupture’s tip. This range is sufficiently far to enable the large variations of

and its final residual value. Final residual values were defined as the average value in the range of 20–25 mm behind the rupture’s tip. This range is sufficiently far to enable the large variations of  and σyy to relax.

and σyy to relax.

In the same way, δA was defined from the point of maximal compression in A,before the reduction, to a third of the difference between the residual value (at 20–25 mm behind the rupture tip) of A and its minimal value.

The synchronization of  (t), measured by the strain gauges, together with the A(x,t), measured by the fast camera, requires precise knowledge of strain gauge locations. These were found using a reference image at the beginning of each experiment. The error in determining the locations is about ∼0.4–1 mm. This is smaller than the average phase shift between δv and δΑ which correspond to∼1.5–2 mm.

(t), measured by the strain gauges, together with the A(x,t), measured by the fast camera, requires precise knowledge of strain gauge locations. These were found using a reference image at the beginning of each experiment. The error in determining the locations is about ∼0.4–1 mm. This is smaller than the average phase shift between δv and δΑ which correspond to∼1.5–2 mm.

Data availability

The authors declare that the data supporting the findings of this study are available within the article.

Additional information

How to cite this article: Shlomai, H. & Fineberg, J. The structure of slip-pulses and supershear ruptures driving slip in bimaterial friction. Nat. Commun. 7:11787 doi: 10.1038/ncomms11787 (2016).

References

Rubinstein, S. M., Cohen, G. & Fineberg, J. Detachment fronts and the onset of dynamic friction. Nature 430, 1005–1009 (2004).

Ben-David, O., Rubinstein, S. M. & Fineberg, J. Slip-stick and the evolution of frictional strength. Nature 463, 76–79 (2010).

Svetlizky, I. & Fineberg, J. Classical shear cracks drive the onset of dry frictional motion. Nature 509, 205–208 (2014).

Passelegue, F. X., Schubnel, A., Nielsen, S., Bhat, H. S. & Madariaga, R. From sub-rayleigh to supershear ruptures during stick-slip experiments on crustal rocks. Science 340, 1208–1211 (2013).

Rice, J. in Mechanics for a New Mellennium eds Aref H., Phillips J. W.) Ch. 1, 1–24Springer (2002).

Lykotrafitis, G. & Rosakis, A. J. Dynamic sliding of frictionally held bimaterial interfaces subjected to impact shear loading. Proc. R. Soc. A 462, 2997–3026 (2006).

Rosakis, A. J., Xia, K., Lykotrafitis, G. & Kanamori, H. in Treatise on Geophysics (ed. Schubert, G.) 153–192Elsevier (2007).

Ampuero, J. P. & Ben-Zion, Y. Cracks, pulses and macroscopic asymmetry of dynamic rupture on a bimaterial interface with velocity-weakening friction. Geophys. J. Int. 173, 674–692 (2008).

Lu, X., Lapusta, N. & Rosakis, A. J. Pulse-like and crack-like ruptures in experiments mimicking crustal earthquakes. Proc. Natl Acad. Sci. USA 104, 18931–18936 (2007).

Weertman, J. Unstable slippage across a fault that separates elastic media of different elastic constants. J. Geophys. Res. 85, 1455–1461 (1980).

Rice, J. R. Elastic fracture-mechanics concepts for interfacial cracks. J. Appl. Mech. 55, 98–103 (1988).

Andrews, D. J. & Ben-Zion, Y. Wrinkle-like slip pulse on a fault between different materials. J. Geophys. Res. 102, 553–571 (1997).

Ben-Zion, Y. Dynamic ruptures in recent models of earthquake faults. J. Mech. Phys. Sol. 49, 2209–2244 (2001).

Gerde, E. & Marder, M. Friction and fracture. Nature 413, 285–288 (2001).

Adda-Bedia, M. & Ben Amar, M. Self-sustained slip pulses of finite size between dissimilar materials. J. Mech. Phys. Sol. 51, 1849–1861 (2003).

Brener, E. A., Weikamp, M., Spatschek, R., Bar-Sinai, Y. & Bouchbinder, E. Dynamic instabilities of frictional sliding at a bimaterial interface. J. Mechan. Phys. Solids 89, 149–173 (2016).

Shi, Z. Q. & Ben-Zion, Y. Dynamic rupture on a bimaterial interface governed by slip-weakening friction. Geophys. J. Int. 165, 469–484 (2006).

Weertman, J. Subsonic type earthquake dislocation moving at approximately root 2 x shear wave velocity on interface between half spaces of slightly different elastic constants. Geophys. Res. Lett. 29, 1470 (2002).

Ben-Zion, Y. & Huang, Y. Dynamic rupture on an interface between a compliant fault zone layer and a stiffer surrounding solid. J. Geophys. Res. 107, 2042 (2002).

Cochard, A. & Rice, J. R. Fault rupture between dissimilar materials: Ill-posedness, regularization, and slip-pulse response. J. Geophys. Res. 105, 25891–25907 (2000).

Ranjith, K. & Rice, J. R. Slip dynamics at an interface between dissimilar materials. J. Mech. Phys. Sol. 49, 341–361 (2001).

Bhat, H. S., Biegel, R. L., Rosakis, A. J. & Sammis, C. G. The effect of asymmetric damage on dynamic shear rupture propagation II: With mismatch in bulk elasticity. Tectonophysics 493, 263–271 (2010).

Xia, K. W., Rosakis, A. J., Kanamori, H. & Rice, J. R. Laboratory earthquakes along inhomogeneous faults: directionality and supershear. Science 308, 681–684 (2005).

Adams, G. G. Self-excited oscillations of two elastic half-spaces sliding with a constant coefficient of friction. J. Appl. Mech. 62, 867–872 (1995).

Harris, R. A. & Day, S. M. Effects of a low-velocity zone on a dynamic rupture. Bull. Seismol. Soc. Am. 87, 1267–1280 (1997).

Freund, L. B. Dynamic Fracture Mechanics Cambridge (1998).

Langer, S., Olsen-Kettle, L. & Weatherley, D. Identification of supershear transition mechanisms due to material contrast at bimaterial faults. Geophys. J. Int. 190, 1169–1180 (2012).

Ben-Zion, Y. & Andrews, D. J. Properties and implications of dynamic rupture along a material interface. Bull. Seismol. Soc. Am. 88, 1085–1094 (1998).

Dor, O., Rockwell, T. K. & Ben-Zion, Y. Geological observations of damage asymmetry in the structure of the San Jacinto, San Andreas and Punchbowl faults in Southern California: a possible indicator for preferred rupture propagation direction. Pure Appl. Geophys. 163, 301–349 (2006).

Read, B. E. & Duncan, J. C. Measurement of dynamic properties of polymeric glasses for different modes of deformation. Polym. Test. 2, 135–150 (1981).

Rubinstein, S. M., Cohen, G. & Fineberg, J. Visualizing stick-slip: experimental observations of processes governing the nucleation of frictional sliding. J. Phys. D 42, 214016 (2009).

Rubinstein, S. M., Shay, M., Cohen, G. & Fineberg, J. Crack-like processes governing the onset of frictional slip. Int. J. Fract. 140, 201–212 (2006).

Acknowledgements

We acknowledge support from the James S. McDonnell Fund (Grant no. 220020221), the European Research Council (Grant no. 267256) and the Israel Science Foundation (Grants 76/11 and 1523/15). We thank G. Cohen and I. Svetlizky for helpful comments.

Author information

Authors and Affiliations

Contributions

H.S. performed the measurements. Both authors contributed to the analysis and writing the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Shlomai, H., Fineberg, J. The structure of slip-pulses and supershear ruptures driving slip in bimaterial friction. Nat Commun 7, 11787 (2016). https://doi.org/10.1038/ncomms11787

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms11787

This article is cited by

-

Geometric controls on cascading rupture of the 2023 Kahramanmaraş earthquake doublet

Nature Geoscience (2023)

-

The role of pore fluids in supershear earthquake ruptures

Scientific Reports (2023)

-

Chasing supershear earthquakes

Nature Geoscience (2022)

-

Transition from sub-Rayleigh anticrack to supershear crack propagation in snow avalanches

Nature Physics (2022)

-

Global frequency of oceanic and continental supershear earthquakes

Nature Geoscience (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.