Abstract

Knowledge of the sound velocity of core materials is essential to explain the observed anomalously low shear wave velocity (VS) and high Poisson’s ratio (σ) in the solid inner core. To date, neither VS nor σ of Fe and Fe-Si alloy have been measured under core conditions. Here, we present VS and σ derived from direct measurements of the compressional wave velocity, bulk sound velocity, and density of Fe and Fe-8.6 wt%Si up to ~230 GPa and ~5400 K. The new data show that neither the effect of temperature nor incorporation of Si would be sufficient to explain the observed low VS and high σ of the inner core. A possible solution would add carbon (C) into the solid inner core that could further decrease VS and increase σ. However, the physical property-based Fe-Si-C core models seemingly conflict with the partitioning behavior of Si and C between liquid and solid Fe.

Similar content being viewed by others

Introduction

Earth’s core, containing a liquid outer core and a solid inner core, constitutes 32% of the mass of the planet, and its composition strongly influences the heat flow in Earth’s deep interior, the crystallization of the inner core, and the evolution of the magnetic field1. High-pressure experiments and geophysical observations have revealed that the iron-nickel outer core and inner core might contain ~10 wt% and ~4 wt% light elements, respectively2,3,4. The proposed light elements include carbon (C), hydrogen (H), oxygen (O), sulfur (S), and silicon (Si), but the identity and relative amounts of the light elements are still debated. Evidence from geochemistry5, metal–silicate partitioning experiments6,7, and isotope fractionation experiments8,9 supports Si as the dominant light element. C might also be present in the Earth’s core due to its abundance in primitive chondritic meteorites10, and its siderophile nature during metal-silicate differentiation11,12,13. Any proposed composition models of the core must simultaneously satisfy the core density (ρ), the bulk sound velocity (VB) of the liquid outer core, and the compressional wave velocity (VP) and shear wave velocity (VS) of the solid inner core, defined by seismic observations14,15. However, it has been challenging to measure VP at pressure (P) and temperature (T) relevant to the Earth’s core conditions, and even more challenging for the measurements of VS. Hence, measurements on core materials need to be extrapolated to core conditions to compare them with the seismic observations.

The extrapolation of VP is usually made according to Birch’s law2, which assumes a linear relationship between ρ and VP. It is still debated whether Birch’s law holds under high P-T conditions. For example, static data by inelastic X-ray scattering (IXS) showed that the VP-ρ relation for iron16 follows Birch’s law up to 93 GPa and 1100 K. On the other hand, measurements by IXS17,18 and nuclear-resonant inelastic X-ray scattering (NRIXS)19 showed that VP decreases with temperature (<3000 K). The static data combined with the early shockwave data20 indicate that Birch’s law does not hold at moderate and high temperature. The disagreement on Birch’s law would significantly affect the estimation of the amounts of Si in the inner core depending on models of the temperature effect on VP, ranging from 1–2 wt%21, and 3–6 wt%22, to 8 wt%17.

For VS of iron alloys, most of the data were derived from NRIXS measurements at high pressure and room temperature23,24,25,26. Estimate of the temperature effect at moderate and high temperature may be doubtful because the extraction of the phonen density of state is from the NRIXS spectra based on a quasi-harmonic model16. Therefore, no reliable VS data of iron alloys are available under the Earth’s core conditions. Comparison of the experimental VS measurements with the seismic observations indicates that the extrapolated VS of iron at 300 K is approximately two times of the inner core value, and the extrapolated Poisson’s ratio (σ) of iron is approximately half of that observed in the inner core23. High temperature and the presence of certain light elements such as C27,28 in the Earth’s inner core are expected to decrease the VS value and increase the σ value to match the observations. To model the VS profile of the inner core, we need to determine the temperature and compositional dependence of VS of iron alloys under high P-T conditions relevant to the Earth’s inner core.

Computer simulations are capable of calculating ρ,VP, and VS under P-T conditions in the core, but the simulated results have not reached a consensus on the temperature dependence of Birch’s law for VP-ρ and VS of iron. For example, the simulated results considering the effect of anharmonicity29 revealed that both VP and VS of iron decreased with temperature at constant density and could match the seismic data of the inner core. On the other hand, more recent calculations30,31 showed that both VP and VS of iron increased almost linearly with density between 0~5500 K, and proposed that the ρ, VP and VS of Fe60Si2C2 (with 1.6 wt% Si and 0.7 wt% C) at 360 GPa and 6500 K could match the seismic data when considering the pre-melting effect31. However, all simulated VP and VS of iron at 0 K were higher than the extrapolation of experimental data at 300 K.

From the experimental measurements and theoretical calculations of VP and VS reported so far, there is no consensus on the temperature dependence of VP and VS of iron and iron alloys at high pressure and temperature (Fig. 1). Here, we report new direct measurements of VP and VB of Fe and Fe–Si alloy (8.6 wt% Si) by shock compression to investigate the temperature dependence on VP, VS and σ under conditions relevant to the Earth’s core. The results provide a test of Birch’s law at simultaneous high pressure and temperature and determine if Si is a viable light element in the inner core.

a The measured VP along Hugoniot by the RIT (red solid circles) and the OAT (red open circles) are compared with previous shockwave data20,34. The solid red line represents the linear fit to the VP measurements for solid Fe. The static VP data by NRIXS23,24,25,26 and IXS16,35 are also plotted for comparison. The measured VB along Hugoniot by the RIT and the derived VS from this study are shown by red circles, compared with NRIXS data with a natural 57Fe isotope concentration at 300 K23,24,25,26. The black dashed line for VB is calculated from the equation of state at 300 K, and the red dashed VB-line is the calculated VB from Hugoniot equation of state. The black and red dashed lines for VS represent the calculated results from VP and VB, at 300 K and along Hugoniot, respectively. b The derived Poisson’s ratios σ from this study are compared with the room-temperature NRIXS data. All measurements are compared with the observed values (black crosses) from PREM14. The boundaries of the melting region (shaded area) were determined according to the discontinuities of the sound velocity.

Results

Sound velocity determination

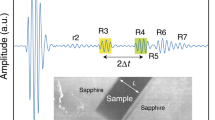

Using the reverse-impact technique (RIT)32,33 and optical analyzer technique (OAT)20,33, the sound velocities of Fe and Fe-8.6 wt% Si (hereafter Fe-8.6Si) were measured with a two-stage light gas gun. The experimental setup and the Lagrangian wave propagation diagram for the RIT are depicted in Supplementary Fig. 1. The data processing method is described in the Methods section. The RIT signals for Fe and Fe-8.6Si are shown in Supplementary Fig. 2. The RIT experiments produce both VP and VB measurements. To improve the accuracy, we take the derivative of the particle velocity with respect to time to pinpoint the arrival time of the rarefaction wave and the elastic-plastic transition point (Supplementary Fig. 3). Supplementary Table 1 lists the direct measurements of VP and VB. Then we obtained the shear wave velocity via VS = [3(VP2 − VB2)/4]1/2 and the Poisson’s ratio via σ = 0.5(VP2 − 2VS2)/(VP2 − VS2).

Because of the low impedance of the lithium fluoride (LiF) window, the maximal pressure reached by the RIT is limited to ~160 GPa. For higher pressures, the VP was obtained by the OAT, which utilizes multiple samples with different thicknesses to determine the catch-up thickness for accurate measurements of the sound velocity. The experimental setup and Lagrangian wave propagation diagram for the OAT are illustrated in Supplementary Fig. 4. Supplementary Fig. 5 shows representative signals and the determined catch-up thickness of experiment 180102 at 126 GPa. Similarly, we also take the derivative of the particle velocity with respect to time to accurately determine the arrival time of the rarefaction wave at the sample/window interface. Supplementary Table 2 lists the measured VP along with the Hugoniot parameters. Using the thermodynamic parameters shown in Supplementary Table 3, we calculated VB, and then obtained VS and σ from the calculated VB and measured VP.

Hugoniot velocity and density measurements on iron

The compressional wave velocity VP of iron along the Hugoniot measured by Brown and McQueen20 is often used to assess the effect of temperature on VP by comparing them with static data at room temperature. Figure 1a shows our experimental VP for iron at simultaneously high pressures and temperatures in the range of 56.8~234.0 GPa and 1073~5417 K, respectively. The data show a linear velocity-density relationship, Vp = −2.89(±0.10) + 1.09(±0.02)ρ, up to 180 GPa (corresponding to 11.77 g/cm3) for solid iron. At the same density, our measured VP values are 1.7~5.3% larger than previous data20 by shock compression but are consistent with subsequent measurements by improved techniques34. The typical uncertainties in velocity measurements are 1.7~3.1% (Supplementary Tables 1 and 2). The calculated temperatures of our Hugoniot data range from 1073 K at 56.8 GPa to 3919 K at 180.1 GPa. However, the measured VP data along the Hugoniot are almost identical to the recent static data for hexagonal close-packed (hcp) iron at 300 K by IXS35 and the corrected data (refer to the method26) by NRIXS23,24,25,26 for iron with a natural 57Fe isotope concentration. The measured VP data are also consistent with the IXS data up to 1110 K obtained by stable external heating16. These results demonstrate that Birch’s law still holds for the VP of iron at high temperature.

Our new Hugoniot density-pressure measurements are consistent with previous shock compression data36 (Fig. 2). Using Hugoniot density-pressure data36 and static 300 K isotherm4, we calculate VP as a function of pressure constrained by Birch’s law. Figure 2 shows consistent VP results at room temperature and along Hugoniot between the measurements23,24,25,26 and calculations. Due to the quasi-harmonic and anharmonic effect at high temperature, both ρ and VP of iron under shock compression gradually deviate from the static room-temperature data at same pressure. But the linear relationship between VP and ρ does not change, indicating the anharmonic effect does not play a significant role in Birch’s law. The linear density-velocity relationship defined by Birch’s law would allow a reliable extrapolation of VP to core conditions for comparison with seismic models such as PREM14.

The Hugoniot densities of Fe36 are compared with new Hugoniot data of this study and static data at 300 K4, along with the fitted results represented by the dashed lines. The red solid circles represent the measured VP under shock compression (this work), compared with the static VP data23,24,25,26,35. The black and red curves represent the calculated VP as a function of pressure along 300 K and shock temperature, using Birch’s law and equations of state of Fe.

Figure 1a also shows the direct measurements of VB from the RIT along with the calculated VB from equation of state. The VB obtained by both methods are in an excellent agreement. Static data23,24,25,26 showed that the VB of pure iron increases linearly with density at 300 K. The shockwave data show a systematic deviation from the room-temperature data due to the temperature effect. From the measurements of VP and VB, we calculate VS at the measured densities (Fig. 1a). At room temperature, VS linearly increases with density, expressed as VS = −1.08(±0.03) + 0.52(±0.03)ρ. The VS along Hugoniot are systematically lower than the room-temperature values, showing shear softening with increasing temperature. The VS values drop significantly at 12.06 and 12.26 g/cm3, indicating initiation of melting (Fig. 1a). Within the solid region, the effect of temperature on VS is dependent on density and temperature (Fig. 3a). The rate of change of VS in temperature, |(ΔVS/ΔT)V|, decreases with density by an exponential function and increases with temperature at a constant density. At 6000 K and 13.04 g/cm3, relevant to inner core condition, VS of iron decreases at a rate of |(ΔVS/ΔT)V| ≈ 0.12 ms−1K−1, much less than a calculated value of 0.48 ms−1K−1 by simulations29. The weak temperature dependence of VS makes more difficult to match the observed low VS in the inner core by the high-temperature effect alone.

a The calculated ΔVS/ΔT increase with density along 2000K (black line), 4000 K (red line) and 6000 K (blue line) isotherms. b The calculated Δσ/ΔT decrease with density along 2000 K (black line), 4000 K (red line) and 6000 K (blue line) isotherms. The solid and dashed lines represent the values of Fe and Fe-8.6Si, respectively, compared with the ab initio calculations (red solid circle)29.

Figure 1b shows the calculated Poisson’s ratio σ that increases with density along the Hugoniot. The elevated σ values along the Hugoniot relative to the 300 K isotherm indicate a positive effect by high temperature (Fig. 1b). Figure 3b shows the effect of temperature and density on σ. The (Δσ/ΔT)V for iron can be expressed as an exponential function of density, with a positive temperature correlation. At 6000 K and 13.04 g/cm3, σ increases at a rate of (Δσ/ΔT)V = 0.90 × 10−5 K−1, less than a predicted value of 2.33 × 10−5 K−1 by simulations29.

Our new Hugoniot velocity measurements on pure iron below melting provide a direct evaluation of the temperature effect on the shear wave velocity and the Poisson’s ratio. We also observed melting at a pressure between 180 and 210 GPa, indicated by a large drop in VP and VS and a fast rise in σ. The onset of melting of iron under shock compression has been an intense debate. The data by Brown and McQueen20 showed two discontinuities in sound velocity at 200 GPa and 243 GPa, respectively, whose explanation has been controversial. New in-situ X-ray diffraction measurements by static compression have ruled out possible solid phase transition below melting37. Additional shock experiments by Nguyen and Holmes34 showed a single discontinuity in VP of iron, indicating onset of melting at ~225 GPa. Our VP measurements indicate that experiments at 210 GPa and 234 GPa are in the melting region.

Hugoniot velocity measurements on iron-silicon alloy

In order to evaluate the effect of Si on the shear wave velocity, we also measured the sound velocities of Fe-8.6Si alloy by shock compression, using the same methodology described for the study of pure iron. Figure 4 shows the measurements of VP and VB for Fe-8.6Si up to 162 GPa (corresponding to 10.68 g/cm3) by the RIT (Supplementary Table 1). The VP measurements were extended to higher pressures between 208 and 239 GPa, with the OAT. We observed the onset of melting at 239 GPa based on the velocity drop. The estimated melting temperature is slightly lower than that of Fe-9Ni-10Si38, which could be caused by uncertainties in the calculated Hugoniot temperature and the estimated porosity (Supplementary Fig. 6).

a The measured VP along Hugoniot by the RIT (red solid circles) and the OAT (red open circles) are compared with shockwave data for Fe-9Ni-10Si38. The solid red line represents the linear fit to the VP measurements for solid Fe-8.6Si alloy. The static VP data of Fe-8Si by NRIXS39 and of Fe–8.9Si35, Fe-8Si17 by IXS are also plotted for comparison. The measures VB along Hugoniot by the RIT and the derived VS from this study are shown by red circles, compared with NRIXS data at 300 K39. The olive open inverted triangles are the corrected values based on the equation of state for Fe-8.6 Si40 and the measured VD by NRIXS39. The black dashed line for VB is calculated from the equation of state at 300 K, and the red dashed VB-line is the calculated VB from Hugoniot equation of state. The black and red dashed lines for VS represent the calculated results from VP and VB, at 300 K and along Hugoniot, respectively. b The derived Poisson’s ratios σ from this study are compared with the room-temperature NRIXS data. All measurements are compared with the observed values (black crosses) from PREM14. The boundaries of the melting region (shaded area) were determined according to the discontinuities of the sound velocity.

Similar to the results of Fe, the measured VP of the Fe–Si alloy also follows Birch’s law, expressed by VP = −2.24(±0.10) + 1.15(±0.03)ρ. The results are in agreements with shockwave data on solid Fe-9 wt%Ni-10 wt%Si alloy38. They are also comparable to the static room-temperature data for hcp Fe-9 wt% Si35 and Fe-8 wt% Si17by IXS, showing no resolvable difference between the room-temperature and Hugoniot data. Early VP measurements for Fe-8 wt% Si by NRIXS39 showed systematically lower values compared to all other studies. The VP and VS by NRIXS were determined according to the calculated VB inferred from the equation of state and measurements of the Debye sound velocity (VD) via 3VD−3 = VP−3 + 2VS−3. Thus, VP is sensitive to the difference in the calculated VB. At room temperature, the calculated VB of Fe-8.0Si39 is systematically smaller than our calculations based on the equation of state of Fe-8.6Si40 (Fig. 4a). Combining the VD measured by NRIXS39 with the VB of Fe-8.6Si obtained in this work, the corrected VP of Fe-8.0 wt% Si is in excellent agreement with other static data by IXS and our Hugoniot data (Fig. 4a). The combined dataset shows no temperature effect on Birch’s law.

Both datasets for pure Fe and Fe-8.6Si alloy demonstrated the validity of Birch’s law. Using the linear VP-ρ relationship defined by Birch’s law, we extrapolated VP of Fe-8.6Si to inner core conditions. The extrapolated value is consistent with the ab initio results for Fe-6.7Si between 0~4000 K31, and the calculated VP for Fe-6.6 Si at 5500 K30, but it is about 13.5% larger than the seismically observed value.

Our derived VS values from Hugoniot VP and VB measurements are smaller than those at room temperature, derived from NRIXS, showing temperature-induced softening. It is noted that the VS derived from NRIXS is insensitive to VB data, thus, the corrected VS values are indistinguishable from the original data of Fe-8.0 wt% Si39. The room-temperature VS is linearly related to the density, VS = 1.05(±0.04)+0.32(±0.03)ρ. The extrapolated data to inner-core density are much smaller than the simulated values at 0 K30,31. Under shock compression, VS gradually decreases (Fig. 4a) and σ gradually increases (Fig. 4b) because of the effect of temperature. Similar to the results for pure iron discussed above, the magnitudes of |(ΔVS/ΔT)V| and (Δσ/ΔT)V for Fe-8.6Si also decrease with density by an exponential function and increase with temperature (Fig. 3). At 6000 K and ρ = 13.04 g/cm3, VS decreases at a rate of (ΔVS/ΔT)V = −0.10 ms−1 K−1, and σ increases at a rate of (Δσ/ΔT)V = 0.4 × 10−5 K−1. These rates are generally smaller than that of pure iron at the same conditions.

The above analysis of VP, VS and σ for Fe-8.6Si alloy is assumed no phase transition along the Hugoniot. Based on the calculated shock temperature of Fe-8.6Si40 and the phase relations in Fe–Si alloys under static compression41,42, it is possible that the shocked hcp Fe-8.6Si phase would decompose into a mixture of Si-poor hcp and Si-rich B2 (CsCl-type) phases at pressures above 145 GPa. However, there is no detectable change in the trends of VP, VS and σ above 145 GPa and 2400 K. This implies that either the decomposition process is kinetically prohibited because of the extremely short shock duration, or the physical properties of the decomposed mixture follow the ideal mixing rule43. Neither of these scenarios would affect our analysis because the equation of state and the compressional wave velocity for Fe–Si system can be interpolated using an ideal mixing model.

Using the ideal linear mixing model43, we interpolated the ρ and VP for Fe-6 wt%Si, Fe-4.5 wt% Ni-3.7 wt%Si, and Fe-9 wt% Ni-2.3 wt%Si alloys based on the corresponding values of Fe-23 wt% Ni44, Fe-8.6Si, and Fe. The measured densities of several Fe–Si alloys from static compression experiments are consistent with the calculated results based on our ideal mixing model (Supplementary Fig. 7). The interpolated VP are in a good agreement with the measured VP of Fe-9 wt%Ni-2.3 wt%Si26 and Fe-6 wt%Si22, and broadly consistent with those of Fe-4.5 wt% Ni-3.7 wt%Si21 by IXS (Fig. 5). The measured VP of Fe-5 wt%Si by picosecond acoustics measurements (PAM)45 showed systematically higher values than the interpolation. Figure 5 illustrates that VP of Fe–Si system increase with the Si content of the Fe–Si alloys. It should be noted that the slope of the sound velocity of Fe-Ni is larger than that of pure iron which could influence the extrapolation when Ni is considered as a core component. However, the data range is limited, and data are more scattered. Additional data for Fe-Ni alloy are required to incorporate Ni into the core models.

The black solid squares and red solid circles represent the new VP measurements for Fe and Fe-8.6Si, respectively, compared with static data for various intermediate compositions including Fe-6Si22, Fe-4.5Ni-3.7Si21, Fe-9Ni-2.3Si26, and Fe-5Si45. The data for Fe-Ni alloy, Fe-23Ni44, are also shown for comparison. The solid lines are the linear fits to the experimental data for the end members. The dashed lines represent the calculated Vp for Fe-6Si, Fe-4.5Ni-3.7Si and Fe-9Ni-2.3Si (in weight percent) according to an ideal linear mixing model43.

Compared with the VP, the effect of Si on VS of the Fe–Si alloys is more complicated because VS is expected to decrease with temperature. Supplementary Fig. 8 shows that pure Fe has a stronger dependence of VS on density than the Fe-8.6Si alloy, leading to a higher VS for Fe than that of Fe-8.6Si at high density (>10.5 g/cm3). In contrast to VS, σ of Fe-8.6Si is almost parallel and ~16% larger than that of pure Fe at the same density (Supplementary Fig. 9). Therefore, the net effect is that an increase in the Si content in the alloy would decrease VS and increase σ of the Fe–Si alloy under conditions of Earth’s inner core.

Discussion

We established a thermodynamic model (see Methods) with optimized parameters (Supplementary Table 3) that best describes the experimental data, and calculated the ρ, VP, VS and σ of Fe and Fe-8.6Si along an adiabatic temperature profile T = TICB (ρ/ρICB)γ, with a Grüneisen parameter γ of 1.5. The estimated temperature at the inner core boundary (ICB) TICB ranges from 5200 K to 5700 K, and the calculations were based on a preferred value of 5440 K3. Figure 6 shows the calculated ρ, VP, VS and σ of Fe and Fe-8.6Si with uncertainties, compared with the PREM values in the inner core. The calculated values are listed in Supplementary Table 4. The uncertainties were assessed through propagation of errors associated with the parameters of equations of state, the Grüneisen parameters, and the parameters of Birch’s law for VP. The uncertainties in ρ, VP, VS and σ caused by the temperature uncertainty in the core were also assessed. A 10% uncertainty in TICB contributes ~0.5% uncertainty in ρ and VP, ~1% uncertainty in VS and ~2% uncertainty in σ for iron.

a The calculated densities of Fe (black dash-dot line), Fe-8.6Si (red dash-dot line), Fe-4.5 wt% Si (olive solid line), Fe7C3 (blue dash-dot-dot line) and Fe-1 wt% Si-5 wt% C mixture (magenta dash line) in the inner core assuming a temperature at inner core boundary of 5440 K, are compared to the PREM density profile. b The same comparison is shown for the compressional wave velocity. c The same comparison is shown for the shear wave velocity. d The same comparison is shown for the Poisson’s ratio. The solid circles represent the simulated values for a model composition Fe60Si2C231 at 360 GPa and 5500 K. The thick gray lines represent the PREM14 for the inner core, with the line width representing 0.5% uncertainty in density, 0.5% in VP and 1.1% in Vs. The PREM uncertainty were derived by comparing different Earth’s model14,15. Error bars are included for the calculated values. For the best-matched composition, Fe-1 wt% Si-5 wt% C, the error bars show 1.1 % errors in density, 11.4 % errors in VP, 17.1 % errors in VS and 6.8% errors in σ.

Throughout the Earth’s inner core, the density of Fe and Fe-8.6Si are ~5.3% higher and ~4.6% lower than the PREM values, respectively. A Si content of 4.5 wt.% could explain the density deficit in the inner core (Fig. 6a). For comparison, we calculated the sound velocity and σ for Fe-4.5Si alloy by interpolation. The VP values of Fe, Fe-4.5Si and Fe-8.6Si are almost coincident with each other, ~6.9% higher than the PREM (Fig. 6b). It is not surprising that the VP values of Fe–Si alloys are not sensitive to the Si content under inner core conditions because VP of Fe-Si alloy linearly increases with the Si content at constant density (Supplementary Fig. 10), while the density of Fe–Si alloy linearly decreases with the Si content at the same rate (Supplementary Fig. 11). The analyses show that incorporation of Si alone in the inner core cannot simultaneously satisfy both the density and compressional sound velocity requirements defined by the observations.

Under the conditions of the inner core, the VS of Fe–Si alloy decreases with the Si content. The VS of Fe-4.5Si is ~11 % less than that of Fe, but it is still ~38% larger than the PREM value even with a temperature-induced softening (Fig. 6c). The σ of the Fe–Si system increases with the Si content under inner core’s condition. Accounting for the temperature effect, the σ value of pure Fe at 5440 K increases ~9 % compared with that at room temperature. As a net effect, the σ value of Fe-4.5 Si is ~ 11% less than the PREM value (Fig. 6d).

The observed anomalously low VS and high σ in the inner core were previously attributed to the temperature effect29,30,31. In this work, we provide the first estimate of VS and σ from direct measurements of both VP and VB under simultaneous high temperature and pressure, relevant to the core conditions, and find that neither the temperature nor silicon is the main factor that would explain the observed low VS and high σ in the inner core. Although we observed a considerable decrease in VS and a considerable increase in σ during melting (Figs. 1 and 4), these drastic changes were caused by the effect in the solid-liquid mixing-phase region and not associated with pre-melting behavior. Here, we do not consider that the pre-melting behavior30,31 is a viable mechanism to explain the low VS and high σ in the inner core, because the observed low shear velocity is not limited to the top region of the inner core.

The mismatch in both VP and VS for Fe–Si alloys would rule out Si as the dominant light element in the solid inner core. Any additional light elements incorporated in the inner core would have to further decrease VP and VS to match the observed inner core values. Compared with the available sound velocity measurements of FeHx46, Fe3S47,48, Fe7C327, and Fe3C49, iron carbide Fe7C3 (8.4 wt% C) is the only iron alloy that reduces the VP and VS comparing with pure Fe. Phase relations in the Fe–C system support that a mixture of Fe7C3 and Fe could be a potential composition of the inner core if the C content is high enough50,51. Therefore, we explore possible composition space for an Fe–Si–C core.

Measurements of the sound velocities (VP and VS) of Fe7C3 at room temperature27 yielded VP = 2.16(±1.16) + 0.66(±0.12)ρ and VS,300K = 0.843(±0.439) + 0.242(±0.045)ρ. The VS values at high temperature were calculated by VS = VS,300K + (dVS/dT)ρ (T − 300). Because there is no measurement of the temperature-dependence of VS for Fe7C3, we assumed that Fe7C3 has the same rate of change of VS at different densities for a given temperature as pure Fe (Fig. 3). Our measurements indicate the upper bound of (dVS/dT)v for pure Fe is about −0.124 ms−1K−1 at an inner-core temperature of 6000 K. Using the equation-of-state parameters (Supplementary Table 3) and the velocity functions described above, we calculated ρ, VP, VS and σ for Fe7C3 under core conditions and then compared them to the observed values. Throughout the Earth’s inner core, ρ, VP and VS for Fe7C3 are ~2.2%, ~5.7%, and ~7.7% less than the inner core observations, respectively, whereas the σ value of Fe7C3 is in the range of PREM. Thus, a combination of Si and C in the inner core could match PREM in all four key parameters (ρ, VP, VS, and σ). Using Fe, Fe-8.6Si, and Fe7C3 as the endmembers, the composition of Fe-1Si-5C (1 wt.% Si and 5 wt.% C) would yield the best fit to the observations (Fig. 6). The derived composition represents a global minimum using the best available thermodynamic parameters of the endmembers, and its uncertainty shown in Fig. 6 is propagated from errors associated with the parameters.

Our model calculations were based on interpolation from data of endmembers Fe, Fe-8.6Si and Fe7C3, using ideal mixing model43. Among the measured physical properties, the density measurement has the highest precision. To examine whether the equations of state of the Fe–C-Si alloys follow the ideal mixing model, we calculated the density of Fe93C4Si3 (corresponding to 0.9 wt.% C and 1.6 wt.% Si) using data from the endmembers, Fe4, Fe-8.6Si, Fe7C352 and Fe3C53, and compared the calculated results with the density measurements of the same alloy composition54. The agreement between the calculated and measured densities (Supplementary Fig. 12) suggests that the ideal mixing model is a reasonable interpolation for the analysis. The effect of C on the density in the core can be effectively modeled from the measurements of iron carbides if the C substitution is not interstitial in the structure, which may have a different effect55.

The Fe–Si–C core model has also been tested using ab initio molecular dynamics calculations. Li et al.31 calculated the density and velocities of hcp-FeSiC alloys for various composition combinations and found that the properties of a hcp-Fe60Si2C2 (corresponding to 1.6 wt% Si and 0.7 wt% C) could match the density and sound velocity of the inner core, but at relatively high core temperature. The simulated VP, VS and σ for Fe60Si2C2 at 360 GPa and 5500 K would deviate from the PREM values (Fig. 6).

Adding C into the inner core is merely based on the required match of physical properties between core alloys and the inner core. The incorporation of C into the solid inner core would have consequence for the chemistry of the core. Based on cosmochemical and geochemical consideration, the abundance of the carbon in the Earth’s core ranges from ~0.2 to ~1 wt%5,13. Presence of ~5 wt.% C in the inner core would require that most of carbon entered the solid inner core during core solidification, with less than 0.8 wt.% C in the liquid outer core. Such a distribution of C between the inner and outer cores requires significant modification of melting relations in the Fe–C system at the ICB pressure, namely shifting the eutectic C composition toward the Fe endmember to keep the bulk C content of the core at the iron carbide + liquid region. This apparently contradicts with recent result on the evolution of the eutectic composition in the Fe–C system as a function of pressure, which did not detect significant change of the eutectic C content up to 260 GPa51. Similarly, a silicon-poor inner core requires to reconcile with seemingly robust conclusion of high Si content in the core from accretion and differentiation models6,7. The solution to this inner core paradox between the mineral physics models and geochemical and petrological constraints might lie in our understanding of melting relations in a multi-component iron alloy system at the ICB conditions. Therefore, further experiments should investigate the partitioning of C and Si between the solid and liquid iron at the inner core boundary, as well as the sound velocity of Fe–C–Si alloy under conditions relevant to the Earth’s inner core.

Methods

We used two-stage light gas guns at the Institute of Fluid Physics of China Academy of Engineering Physics and at the High Pressure Physics and Novel Materials Research Center in Wuhan University of Technology to measure the sound velocities of the Fe and Fe-8.6Si alloys. The discs of iron were from Trillion Metals Co., Ltd, with a chemical purity of 99.97(±0.05) wt% and an average density of 7.859(±0.007) g/cm3. The Fe–Si alloy powder with an average grain size of ~10 µm was from Goodfellow Co., Ltd., and was sintered in a large-volume cubic multi-anvil apparatus at 5 GPa and 1200 °C. The average bulk immersion density of the sintered sample is 7.386(±0.021) g/cm3. Electron microprobe analysis of the sintered discs showed uniform distribution of Si with an average Si content of 8.61(±0.02) wt%. The preparation of the Fe-8.6Si sample was described in our previous work40.

The sound velocities of pure Fe and Fe-8.6Si alloy were measured using two complementary methods, the reverse-impact technique (RIT)32,33 and optical analyzer technique (OAT)20,33. For the RIT, a 12-mm sample disc was used as a flyer to directly impact a LiF single-crystal window coated with a 3-µm aluminum film. An 8-µm aluminum foil was mounted in front of the film with epoxy (Supplementary Fig. 1a). Supplementary Fig. 1b shows the Lagrangian distance-time diagram for the reverse-impact experiments. The particle velocity history u(t) at the film/LiF window interface was measured by the displacement interferometer system for any reflector (DISAR), as shown in Supplementary Fig. 2. When the flyer with thickness h impacted the window at time t0, indicated by a sharp increase in particle velocity, a shock wave with velocity DS and an elastic precursor wave with velocity De were produced in the flyer. If DS is less than De, the elastic precursor wave De first reaches the rear surface of flyer, then is reflected as a rarefaction wave with velocity VP,0 (compressional velocity under ambient conditions), and finally meets the oncoming shock wave DS at position h132.

Then, DS is reflected as a rarefaction wave transported with velocity VP,L in the flyer and reaches the Al foil/LiF interface at time t1, indicating a decrease in particle velocity (Supplementary Fig. 3). The compressional velocity in the Lagrangian coordinates is determined by

If the plastic shock velocity DS is equal to or greater than the elastic precursor wave velocity at the Hugoniot elastic limit (HEL), only a single shock wave is observed, which is known as the “overdriven” condition. The overdriven conditions for Fe and Fe-8.6Si are expected to occur at stresses of 61(±2) GPa and 49(±2) GPa, respectively, based on their compressional velocities56 under ambient condition. When the pressure is above the overdriven condition, position h1 in Eqs. (1) and (2) is replaced with the flyer thickness h. Multiplying VP,L with ρ0/ρ (the ratio of the initial and compressed densities), we obtain the compressional wave velocity VP in Eulerian coordinates. The main sources of the uncertainty in the measured VP are from the uncertainties in the thickness h of the sample, the shock wave DS, the arrival time of the rarefaction wave t1, and the initial and compressed densities. The errors in the measured VP for Fe and Fe-8.6Si range from 1.5~3% (Supplementary Table 1).

When the elastic-plastic transition (EPT) point at time t2 during unloading is determined, the bulk velocities VB at released pressure can also be obtained by replacing t1 with t2 in Eq. (2). However, the EPT point at t2 is very subtle in the particle velocity history record and difficult to determine precisely. To obtain VB precisely, we take the derivative of particle velocity u(t) with respect to time (du/dt). The du/dt data have a minimum value due to EPT which is considered as the inflexion of particle velocity history u(t). Supplementary Fig. 3a, b shows the particle velocity and its derivative as a function of time for experiment 170314. Supplementary Fig. 3c shows the Lagrangian sound velocity as a function of the particle velocity during unloading. During plastic unloading, the Lagrangian sound velocity increases linearly with the particle velocity. Extrapolating the linear relation to the particle velocity just before unloading yields a Lagrangian bulk velocity VB,L under compression. Multiplying VB,L by ρ0/ρ, we obtain the bulk velocity VB in Eulerian coordinates. The main sources of the uncertainty in VB are the uncertainties in h, DS, t2 and the fitted parameters for the Lagrangian sound velocity during plastic unloading. The errors in the measured VB range from 1.9~3.8% (Supplementary Table 1).

From the direct measurements of VP and VB, we obtained the shear wave velocity via VS = [3(VP2 − VB2)/4]1/2 and Poisson’s ratio via σ = 0.5(VP2 − 2VS2)/(VP2 − VS2), listed in Supplementary Table 1. Compared with VP and VB, the propagated errors in VS and σ are considerably large, ranging from 6~13% and 8~18%, respectively. Nevertheless, the derived VS and σ along Hugoniot provide a direct evaluation of the temperature effect on shear wave velocity and Poisson’s ratio when compared with static measurements at room temperature.

We also performed VP measurements on pure Fe and Fe-8.6Si alloy at higher pressure using the optical analyzer technique (OAT). Supplementary Fig. 4 illustrates the experimental configuration of a flyer (Fe or Ta) impacting the sample with different thicknesses and the Lagrangian distance-time diagram showing the flyer and sample interaction. Supplementary Fig. 5a–c show three particle velocity history records at the interface between the Ta foil and LiF window for the experiment 180102 with three different sample thicknesses. A linear fit of the measured time interval as a function of the sample thickness provides the catch-up thickness (Supplementary Fig. 5d). The details of the sound velocity determination from the measured catch-up thickness of the sample and the known flyer properties were discussed by Huang et al33. The main sources of the uncertainty are from the uncertainties in the thickness of the sample, the shock velocities in the flyer and sample, and the compressional wave velocity in the flyer if its material is different from that of the sample. The uncertainty in VP measured by OAT ranges from 1~4% (Supplementary Table 2).

We also calculated the bulk sound velocities VB from the Hugoniot equation of state for solid Fe and Fe-8.6Si alloy based on following thermodynamic model.

The value (dP/dV)V,T was obtained from the Grüneisen equation of state.

where γeff, the effective Grüneisen parameter, includes the lattice and electrons contributions.

The lattice Grüneisen parameter is defined as γl = γ0 (ρ0/ρ)q. γe is the electrons Grüneisen parameter. CV,l = 3 R/µ and CV,e = β0 (ρ0/ρ)κT are the specific heat contributed by the lattice and electrons, respectively. The parameters for Fe, Fe-8.6Si and Fe7C3 were listed in Supplementary Table 3. \({P_{T_{0}}}(V)\) is the equation of state at 300 K, which was calculated from Hugoniot pressure PH (V,TH) by

The shock temperature TH were calculated from the thermodynamic relation20.

Using the third-order Birch–Murnaghan equation of state, the fitted parameters of isothermal bulk modulus K0 and its pressure derivative K0’ are given in Supplementary Table 3.

The calculated bulk sound velocity from the Hugoniot equation of state agrees well with the experimental measurements (Figs. 1 and 4). The main sources of uncertainty in the model calculations of VB are uncertainties in the Hugoniot parameters (C0, λ), the lattice contributions to the Grüneisen parameter, and the electronic and anharmonic contributions to the specific heat. The thermodynamic parameters and their errors for Fe and Fe-8.6Si are listed in Supplementary Table 3. The uncertainties in the Hugoniot parameters directly contribute to the uncertainties in the derived equation of state, having a large influence on the propagated errors in VB. Along Hugoniot, the propagated errors in the calculated VB for Fe and Fe-8.6Si are approximately 2% and 5%, respectively, which are smaller than the errors in the calculated VS in the ranges of 7~20% and 23~30%, respectively. The errors in σ for Fe and Fe-8.6Si are 6~8% and 12%, respectively.

Under the conditions of Earth’s inner core, the density and sound velocity in the Fe–Si–C system are estimated based on an ideal mixing model

and

where Wi is the weight percent, VP(or S),i and ρi represent the sound velocity and density of the endmember (Fe, Fe-8.6Si or Fe7C3) at the same pressure and temperature. For Fe and Fe-8.6Si, ρ and VB were calculated with Eqs. (3) and (4), and VP data were calculated using Birch’s law. The VS and σ were then calculated from ρ, VB and VP. Because of no direct shock wave measurement for Fe7C3, the thermodynamic parameters for Fe7C3 at high pressure and temperature have not been constrained. We therefore estimated the VS of Fe7C3 using the data at 300 K with an assumed (dVS/dT)V value. The errors of the density and sound velocity of the mixture were calculated based on the following equations.

and

where the subscript P(or S) indicates the compressional or shear velocity. The subscript i represents the ith endmember (Fe, Fe-8.6Si or Fe7C3) at the same pressure and temperature. δρi and δVP(or S),i represent the errors of density and sound velocity of the ith endmember.

Data availability

All data generated or analyzed during this study are included in this published article and its Supplementary Information files.

References

Buffett, B. A., Huppert, H. E., Lister, J. R. & Woods, A. W. On the thermal evolution of the Earth’s core. J. Geophys. Res. 101, 7989–8006 (1996).

Birch, F. Composition of the Earth’s mantle. Geophys. J. R. Astron. Soc. 4, 295–311 (1961).

Hirose, K., Labrosse, S. & Hernlund, J. Composition and state of the core. Annu. Rev. Earth Planet. Sci. 41, 657–691 (2013).

Fei, Y., Murphy, C., Shibazaki, Y., Shahar, A. & Huang, H. Thermal equation of state of hcp-iron: constraint on the density deficit of earth’s solid inner core. Geophys. Res. Lett. 43, 6837–6843 (2016).

McDonough, W. F. Compositional model for the Earth’s core. In The mantle and core.Treatise on Geochemistry, Vol. 2, (ed. Carlson, R. W.) chap. 15 (Elsevier, 2003), pp. 547–568.

Rubie, D. C. et al. Heterogeneous accretion, composition and core–mantle differentiation of the earth. Earth Planet. Sci. Lett. 301, 31–42 (2011).

Fischer, R. A. et al. High pressure metal–silicate partitioning of Ni, Co, V, Cr, Si, and O. Geochim. et Cosmochim. Acta 167, 177–194 (2015).

Fitoussi, C., Bourdon, B., Kleine, T., Oberli, F. & Reynolds, B. C. Si isotope systematics of meteorites and terrestrial peridotites: implications for Mg/Si fractionation in the solar nebula and for Si in the Earth’s core. Earth Planet. Sci. Lett. 287, 77–85 (2009).

Shahar, A. et al. Experimentally determined Si isotope fractionation between silicate and Fe metal and implications for Earth’s core formation. Earth Planet. Sci. Lett. 288, 228–234 (2009).

Wasson, J. T. & Kallemeyn, G. W. Compositions of chondrites. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 325, 535–544 (1988).

Dasgupta, R., Chi, H., Shimizu, N., Buono, A. S. & Walker, D. Carbon solution and partitioning between metallic and silicate melts in a shallow magma ocean: Implications for the origin and distribution of terrestrial carbon. Geochimica et. Cosmochimica Acta 102, 191–212 (2013).

Fischer, R. A., Cottrell, E., Hauri, E., Lee, K. K. & Le Voyer, M. The carbon content of Earth and its core. Proc. Natl Acad. Sci. USA. 117, 8743–8749 (2020).

Wood, B. J., Li, J. & Shahar, A. Carbon in the core: its influence on the properties of core and mantle. Rev. Mineral. Geochem. 75, 231–250 (2013).

Dziewonski, A. M. & Anderson, D. L. Preliminary reference earth model. Phys. Earth Planet. Inter. 25, 297–356 (1981).

Tkalčić, H. & Phạm, T. S. Shear properties of Earth’s inner core constrained by a detection of J waves in global correlation wavefield. Science 362, 329–332 (2018).

Antonangeli, D. et al. Simultaneous sound velocity and density measurements of hcp iron up to 93 GPa and 1100 K: An experimental test of the Birch’s law at high temperature. Earth Planet. Sci. Lett. 331, 210–214 (2012).

Mao, Z. et al. Sound velocities of Fe and Fe-Si alloy in the earth’s core. Proc. Natl Acad. Sci. USA. 109, 10239–10244 (2012).

Sakamaki, T. et al. Constraints on Earth’s inner core composition inferred from measurements of the sound velocity of hcp-iron in extreme conditions. Sci. Adv. 2, e1500802 (2016).

Lin, J. F. et al. Sound velocities of hot dense iron: Birch’s law revisited. Science 308, 1892–1894 (2005).

Brown, J. M. & McQueen, R. G. Phase transitions, Grüneisen parameter, and elasticity for shocked iron between 77 GPa and 400 GPa. J. Geophys. Res. 91, 7485–7494 (1986).

Antonangeli, D. et al. Composition of the Earth’s inner core from high-pressure sound velocity measurements in Fe–Ni–Si alloys. Earth Planet. Sci. Lett. 295, 292–296 (2010).

Sakairi, T. et al. Sound velocity measurements of hcp Fe-Si alloy at high pressure and high temperature by inelastic x-ray scattering. Am. Mineral. 103, 85–90 (2018).

Mao, H. K. et al. Phonon density of states of iron up to 153 gigapascals. Science 292, 914–916 (2001).

Gleason, A. E., Mao, W. L. & Zhao, J. Y. Sound velocities for hexagonally close packed iron compressed hydrostatically to 136 GPa from phonon density of states. Geophys Res. Lett. 40, 2983–2987 (2013).

Murphy, C. A., Jackson, J. M. & Sturhahn, W. Experimental constraints on the thermodynamics and sound velocities of hcp-Fe to core pressures. J. Geophys. Res. 118, 1999–2016 (2013).

Liu, J. et al. Seismic parameters of hcp-Fe alloyed with Ni and Si in the Earth’s inner core. J. Geophys. Res. 121, 610–623 (2016).

Chen, B. et al. Hidden carbon in Earth’s inner core revealed by shear softening in dense Fe7C3. Proc. Natl Acad. Sci. USA 111, 17755–17758 (2014).

Prescher, C. et al. High Poisson’s ratio of Earth’s inner core explained by carbon alloying. Nat. Geosci. 8, 220–223 (2015).

Steinle-Neumann, G., Stixrude, L., Cohen, R. E. & Gülseren, O. Elasticity of iron at the temperature of the Earth’s inner core. Nature 413, 57–60 (2001).

Martorell, B., Wood, I. G., Brodholt, J. & Vočadlo, L. The elastic properties of hcp-Fe1− xSix at Earth’s inner-core conditions. Earth Planet. Sci. Lett. 451, 89–96 (2016).

Li, Y., Vocadlo, L. & Brodholt, J. P. The elastic properties of hcp -Fe alloys under the conditions of the Earth’s inner core. Earth Planet. Sc. Lett. 493, 118–127 (2018).

Duffy, T. S. & Ahrens, T. J. Compressional sound velocity, equation of state, and constitutive response of shock-compressed magnesium oxide. J. Geophys. Res. 100, 529–542 (1995).

Huang, H. et al. Evidence for an oxygen-depleted liquid outer core of the Earth. Nature 479, 513–516 (2011).

Nguyen, J. H. & Holmes, N. C. Melting of iron at the physical conditions of the Earth’s core. Nature 427, 339–342 (2004).

Antonangeli, D. et al. Sound velocities and density measurements of solid hcp-Fe and hcp-Fe–Si (9 wt.%) alloy at high pressure: Constraints on the Si abundance in the Earth’s inner core. Earth Planet. Sci. Lett. 482, 446–453 (2018).

Brown, J. M., Fritz, J. N. & Hixson, R. S. Hugoniot data for iron. J. Appl. Phys. 88, 5496–5498 (2000).

Anzellini, S., Dewaele, A., Mezouar, M., Loubeyre, P. & Morard, G. Melting of iron at Earth’s inner core boundary based on fast X-ray diffraction. Science 340, 464–466 (2013).

Zhang, Y. et al. Experimental constraints on light elements in the earth’s outer core. Sci. Rep. 6, 22473 (2016).

Lin, J. et al. Sound velocities of iron-nickel and iron-silicon alloys at high pressures. Geophys. Res. Lett. 30, 2112–2115 (2003).

Huang, H. et al. Equation of state for shocked Fe-8.6wt% Si up to 240 GPa and 4,670 K. J. Geophys. Res. 124, 8300–8312 (2019).

Fischer, R. A. et al. Phase relations in the Fe–FeSi system at high pressures and temperatures. Earth Planet. Sci. Lett. 373, 54–64 (2013).

Tateno, S., Kuwayama, Y., Hirose, K. & Ohishi, Y. The structure of Fe–Si alloy in Earth’s inner core. Earth Planet. Sci. Lett. 418, 11–19 (2015).

Badro, J. et al. Effect of light elements on the sound velocities in solid iron: implications for the composition of earth’s core. Earth Planet. Sci. Lett. 254, 233–238 (2007).

Kantor, A. P. et al. Sound wave velocities of fcc Fe-Ni alloy at high pressure and temperature by mean of inelastic X-ray scattering. Phys. Earth Planet. Inter. 164, 83–89 (2007).

Edmund, E. et al. Velocity-density systematics of Fe-5wt% Si: constraints on Si content in the Earth’s inner core. J. Geophys. Res. 124, 3436–3447 (2019).

Shibazaki, Y. et al. Sound velocity measurements in dhcp-FeH up to 70 GPa with inelastic X-ray scattering: Implications for the composition of the Earth’s core. Earth Planet. Sci. Lett. 313, 79–85 (2012).

Lin, J. F. et al. Magnetic transition and sound velocities of Fe3S at high pressure: implications for Earth and planetary cores. Earth Planet. Sci. Lett. 226, 33–40 (2004).

Kamada, S. et al. The sound velocity measurements of Fe3S. Am. Mineralogist 99, 98–251 (2014).

Gao, L. et al. Pressure-induced magnetic transition and sound velocities of Fe3C: Implications for carbon in the Earth’s inner core. Geophys. Res. Lett. 35, L17306 (2008).

Fei, Y. & Brosh, E. Experimental study and thermodynamic calculations of phase relations in the Fe–C system at high pressure. Earth Planet. Sci. Lett. 408, 155–162 (2014).

Mashino, I., Miozzi, F., Hirose, K., Morard, G. & Sinmyo, R. Melting experiments on the Fe–C binary system up to 255 GPa: constraints on the carbon content in the Earth’s core. Earth Planet. Sci. Lett. 515, 135–144 (2019).

Chen, B. et al. Magneto-elastic coupling in compressed Fe7C3 supports carbon inEarth’s inner core. Geophys. Res. Lett. 39, L18301 (2012).

Sata, N. et al. Compression of FeSi, Fe3C, Fe0. 95O, and FeS under the core pressures and implication for light element in the Earth’s core. J. Geophys. Res. 115, B09204 (2010).

Pamato, M. G. et al. Equation of state of hcp Fe-C-Si alloys and the effect of C incorporation mechanism on the density of hcp Fe alloys at 300 K. J. Geophys. Res. 125, e2020JB020159 (2020).

Yang, J., Fei, Y., Hu, X., Greenberg, E. & Prakapenka, V. B. Effect of carbon on the volume of solid iron at high pressure: Implications for carbon substitution in iron structures and carbon content in the Earth’s inner core. Minerals 9, 720 (2019).

Liu, J., Lin, J. F., Alatas, A. & Bi, W. Sound velocities of bcc-Fe and Fe0.85Si0.15 alloy at high pressure and temperature. Phys. Earth Planet. Inter. 233, 24–32 (2014).

Acknowledgements

We thank Q. Shen (the Sate Key Lab of Advanced Technology for Materials Synthesis), M. Yang and C. Shen (the Materials Research and Testing Center) for sample preparation, and R. Tao for chemical analysis of the samples. This work was supported by the National Science Foundation of China (grant 41874103, 51932006), and the Fundamental Research funds for the Central Universities (grants WUT 14050). Additional support for this collaborative research was provided by the Carnegie Institution for Science, and National Science Foundation grants (EAR-1619868) to YF.

Author information

Authors and Affiliations

Contributions

H.H. and Y.F. designed the project. H.H., L.F., X.L., F.X., Y.W., G.Y., C.L., Q.W., J.W., X.W., L.C., and Y.F. participated the data collection and analysis. H.H and Y.F. were responsible for data interpretation and wrote the manuscript. L.F., X.L., F.X., Y.W., G.Y., C.L., Q.W., J.W., X.W., and L.C. participated the discussion and provided comments on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Guillaume Morard and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Huang, H., Fan, L., Liu, X. et al. Inner core composition paradox revealed by sound velocities of Fe and Fe-Si alloy. Nat Commun 13, 616 (2022). https://doi.org/10.1038/s41467-022-28255-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-28255-2

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.