Abstract

Compared to transition metal dichalcogenide (TMD) monolayers, rhombohedral-stacked (R-stacked) TMD bilayers exhibit remarkable electrical performance, enhanced nonlinear optical response, giant piezo-photovoltaic effect and intrinsic interfacial ferroelectricity. However, from a thermodynamics perspective, the formation energies of R-stacked and hexagonal-stacked (H-stacked) TMD bilayers are nearly identical, leading to mixed stacking of both H- and R-stacked bilayers in epitaxial films. Here, we report the remote epitaxy of centimetre-scale single-crystal R-stacked WS2 bilayer films on sapphire substrates. The bilayer growth is realized by a high flux feeding of the tungsten source at high temperature on substrates. The R-stacked configuration is achieved by the symmetry breaking in a-plane sapphire, where the influence of atomic steps passes through the lower TMD layer and controls the R-stacking of the upper layer. The as-grown R-stacked bilayers show up-to-30-fold enhancements in carrier mobility (34 cm2V−1s−1), nearly doubled circular helicity (61%) and interfacial ferroelectricity, in contrast to monolayer films. Our work reveals a growth mechanism to obtain stacking-controlled bilayer TMD single crystals, and promotes large-scale applications of R-stacked TMD.

Similar content being viewed by others

Introduction

In addition to the remarkable properties of monolayer transition metal dichalcogenide (TMD), bilayer TMD possess superior physical properties owing to the additional degrees of freedom, i.e., twist angle and stacking1,2,3,4,5,6,7,8,9,10. Typically, bilayer TMD exhibit two main stacking configurations: a rhombohedral-stacked (R-stacked) structure where the layers are parallelly stacked and a hexagonal-stacked (H-stacked) structure where they are antiparallelly stacked. In practice, the R-stacked bilayer TMD, which break both the in-plane and out-of-plane mirror symmetries, are highly desirable because of their exceptional optical, electrical, photovoltaic, and ferroelectric properties11,12,13,14,15,16. To fully realize their potential applications, large R-stacked bilayer TMD single crystals are urgently needed.

To achieve the growth of R-stacked bilayer TMD single crystals, several fundamental challenges need to be addressed: (i) reducing the nucleation barrier of bilayer TMD to ensure the preferred bilayer growth to monolayer; (ii) ensuring the simultaneous growth of both upper and lower layers of TMD to produce a uniform film; and (iii) effectively distinguishing between R- and H-stacked configurations to ensure only R-stacking in the bilayer TMD. To date, considerable efforts have been devoted to addressing the first two challenges, and polycrystalline bilayer TMD films have been reported very recently11,12,13,14,15,16. Nevertheless, as R- and H-stacked bilayer TMD are both thermodynamically favourable and have similar formation energies, uncontrollable stacking and grain boundaries are inevitable in the grown bilayer TMD films13,14.

Here, we report the remote epitaxy of centimetre-scale single-crystal R-stacked bilayer WS2 films on a-plane sapphire. Our strategy demonstrates that (i) a high W source flux at high temperature can effectively decrease the bilayer nucleation barrier, (ii) the choice of substrates with weak substrate-WS2 interactions can precisely control the growth of both upper- and lower-layer WS2 with nearly identical sizes, and (iii) symmetry breaking in sapphire with atomic steps can pass through the lower layer and control the R-stacking of the upper layer. The uniformly aligned R-stacked bilayer WS2 islands will ultimately seamlessly stitch into a continuous single-crystal film.

Results

Uniform nucleation and growth of bilayer WS2 islands

In principle, two approaches are typically used to obtain uniform R-stacked bilayer TMD: layer-by-layer epitaxy and simultaneous bilayer nucleation epitaxy. In the case of layer-by-layer epitaxy, due to the difficulty in achieving clean interfaces over large areas and the precise nucleation control of the upper layer, the growth of R-stacked uniform bilayer single crystals is nearly impossible14. In contrast, in simultaneous bilayer nucleation epitaxy, both the orientations and stacking configurations of the upper and lower layers are simultaneously determined at the early growth stage. Therefore, if the bilayer nucleation can be controlled with the same orientation, large-scale bilayer TMD single crystals is possible.

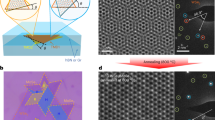

Because the nucleation barrier of bilayer TMD is usually very high, the growth of monolayer TMD on sapphire surface is generally preferred17,18,19,20,21,22,23,24,25. Therefore, new strategies need to be explored to effectively decrease the nucleation barrier (Fig. 1a). To address this issue, we conducted density functional theory (DFT) calculations and set up a thermodynamic model to investigate the nucleation and growth of bilayer WS2 under different conditions (see Methods and Supplementary Note 1 for details). Since the source of S is usually present in excess during TMD growth, the concentration of W becomes a controlling factor13. The calculated Gibbs free energy of bilayer WS2 demonstrates that the nucleation barrier can be significantly reduced from 6.75 to 1.55 eV by increasing the concentration of the W source and temperature (Fig. 1b; the corresponding \(\varDelta {\mu }_{W}\) values range from 0 to 0.09 eV, where \(\varDelta {\mu }_{W}\) represents the chemical potential difference of the W source). A change in \(\varDelta {\mu }_{W}\) of ~0.09 eV can be achieved by increasing the temperature for ~150 K or by increasing the partial pressure of the W source by ~30 Pa (Supplementary Fig. 1a). This change can increase the bilayer nucleation rate by ~6\(\times\)107 times (Supplementary Fig. 1b). In our experiment, the high partial pressure of the W source is achieved by using sufficient tungsten oxide under high temperature (see Methods for details).

a Schematic diagram of the route to grow uniform bilayer WS2. Nucleation barrier and interfacial coupling should be both considered. TMD represents the transition metal dichalcogenide, Esub-TMD represents the coupling between the substrate and TMD, and ETMD-TMD represents the coupling between two TMD layers. b The calculated Gibbs free energy of the bilayer WS2 versus the chemical potential differences (Δμ) of the W source, where the point with the highest G value is the nucleation barrier of bilayer WS2. The nucleation barriers decrease with the increase of Δμ (shown with an arrow). c The van der Waals interaction between WS2/c-Al2O3, WS2/WS2 and WS2/a-Al2O3, respectively. Optical images of monolayer WS2 (d) and bilayer WS2 (e) islands obtained under low and high W flux conditions, respectively. f Atomic force microscopy (AFM) image of an as-grown bilayer WS2 island. g Height profile of the bilayer WS2 island in (f). 1 L and 2 L represent monolayer and bilayer WS2, respectively.

Once the bilayer nucleation barrier is overcome, the thermodynamic stability of the bilayer WS2 during growth is influenced by two primary factors: (i) the energy penalty upon edge formation for the upper layer TMD and (ii) the competition of the van der Waals (vdW) interaction between the substrate-TMD and TMD-TMD. The edge formation energies and vdW interactions between TMD-TMD remain constant for a specific type of TMD. Therefore, the thermodynamic stability is mainly determined by the substrate-TMD interaction. Strong interaction leads to a significantly higher energy penalty upon upper layer formation, favouring the growth of only monolayer. Therefore, the selection of a substrate with weak vdW interactions is crucial for achieving uniform bilayer TMD growth.

In line with this principle, we calculated the interfacial couplings of WS2 and various sapphire planes, and found that the vdW interaction between a-plane sapphire and WS2 is much weaker than the WS2-WS2 interaction, while the c-plane sapphire exhibits a much stronger interaction with WS2 (Fig. 1c). Thus, we selected a-plane sapphire as the target substrate and the calculated Gibbs energy difference between monolayer and bilayer WS2 demonstrated that bilayer WS2 became considerably more thermodynamically favourable than the monolayer WS2 beyond a small critical size (~11 nm; see details in Supplementary Fig. 1c). In contrast, monolayer WS2 is always preferred on c-plane sapphire (Supplementary Fig. 2). With this design, we successfully achieved monolayer and bilayer WS2 islands with low and high W fluxes, respectively, on a-plane sapphire (Fig. 1d, e). Subsequent atomic force microscopy (AFM), Raman and photoluminescence (PL) characterizations further confirmed the nature of the uniform bilayer islands (Fig. 1f, g and Supplementary Fig. 3a, b).

Remote epitaxy mechanism of R-stacked bilayer WS2

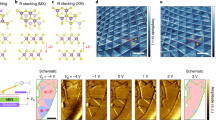

In addition to achieving uniform bilayer WS2 growth, precise control of the lattice orientation and stacking configuration is the key for obtaining R-stacked bilayer WS2 single crystals (Fig. 2a, b). On a-plane sapphire, both antiparallel H- and R-stacked bilayers are thermodynamically favourable with nearly degenerate formation energies (upper plane in Fig. 2b); thus, the single-crystal growth is very challenging. Inspired by the growth of noncentrosymmetric two-dimensional (2D) monolayer hexagonal boron nitride (hBN) and TMD, we introduced parallel atomic steps on sapphire to overcome the energy equivalence of the antiparallel R- and H-stacked bilayer WS2.

a Schematic diagrams of the step-guided epitaxy of bilayer WS2 on high steps. Each layer of TMD bonds to the side of the steps. b Schematic diagrams of the remote epitaxy of bilayer WS2 on atomic steps. The in-plane direction and interlayer stacking of bilayer WS2 can both be tuned by the steps. c Formation energies of R- and H-stacked bilayer WS2 with different rotation angles on a-plane sapphire without steps. Bilayer TMD has the same deep minima as monolayer (θ = 0° and θ = ±60°). d Binding energies of R- and H-stacked bilayer WS2 that across an atomic step on a-plane sapphire.

When these steps are involved in the growth of bilayer TMD single crystals, two mechanisms can be selected: step-guided epitaxy on high steps and remote epitaxy on atomic steps. For epitaxy with high steps, each layer of TMD bonds to the side of the steps, and the stacking configuration is strongly influenced by the atomic structure of the side surface. This step controlled process is highly complex and uncontrollable on a large scale (Fig. 2a)26, leading to the extreme challenge in controlled stacking and single-crystal growth13. For remote epitaxy on atomic steps, the TMD layers are not directly bonded to the steps, and the growth mechanism is similar to the dual-coupling-guided epitaxy27. The TMD-TMD interaction first leads to preferred orientations and stacking configurations of the TMD, and then the remote sapphire step-TMD interaction restricts the orientation into a single one (Fig. 2b). Evidently, the latter approach is more suitable for producing large-area bilayer TMD single crystals.

Experimentally, we observed that the morphology of the steps on a sapphire substrate can be faithfully replicated to the monolayer WS2, even when the height of the steps is only ~2 Å (Supplementary Fig. 4). These results indicate that the underlying steps can tune the growth behaviours of both the lower and upper WS2 layers. To further investigate this phenomenon, we conducted DFT calculations on the bilayer WS2 islands on a-plane sapphire with atomic steps. The calculated data demonstrated that the energy equivalence of the antiparallel R0-WS2, R60-WS2, H0-WS2, and H60-WS2 are broken effectively, and only R0-WS2 was energetically favoured (Fig. 2c, d, the definition of R0-WS2, R60-WS2, H0-WS2, and H60-WS2 is shown in Supplementary Fig. 5). Therefore, the presence of lower layer WS2 did not completely shield the potential field from the sapphire substrates, thereby enabling remote epitaxy of single-crystal bilayer WS2.

Growth of R-stacked bilayer WS2

To verify our design, we conducted chemical vapour deposition (CVD) growth of WS2 on a-plane sapphire substrates (see Methods for details). The experimental results convincingly demonstrated the successful production of single-crystal WS2 films. With the assistance of atomic steps, unidirectionally aligned bilayer WS2 islands could be achieved (Fig. 3a, the bilayer nucleation is shown in Supplementary Fig. 6). The aberration-corrected transmission electron microscopy (TEM) was first conducted to directly show the R-stacking lattice (Supplementary Fig. 7). Second harmonic generation (SHG) characterization was subsequently performed to identify the R-stacked bilayer WS2 at large scale. Due to the non-centrosymmetric lattice of the R-stacked bilayer WS2, the SHG intensity was four times greater than that of the monolayer (Fig. 3b)28. In contrast, the H-stacked bilayer WS2 was centrosymmetric and thus exhibited a negligible SHG signal (Fig. 3b)29. The strong and uniform SHG intensity confirmed the R-stacked configurations of the as-grown bilayer WS2 islands at a large scale (Fig. 3c). Continuous R-stacked bilayer WS2 films could be obtained by increasing the growth time (Fig. 3d).

a Optical image of aligned bilayer WS2 islands. b Second harmonic generation (SHG) spectra of monolayer WS2, bilayer R-WS2 and bilayer H-WS2 samples. c SHG mapping of the as-grown WS2 samples in (a). d Optical image of the sapphire substrate, monolayer (1 L) WS2 and bilayer (2 L) WS2 samples. e Typical selected area electron diffraction (SAED) pattern of the bilayer WS2 samples. f Typical AFM image of the bilayer WS2 samples. g Atomically-resolved scanning transmission electron microscopy (STEM) image from the merged area of two aligned bilayer WS2 islands (namely, 2 L WS2-1 and 2 L WS2-2), showing that no boundary was formed. The dashed lines represent the edges of 2 L WS2-1 and 2 L WS2-2. The box labelled ‘A’ represents a merged area. h Atomically-resolved STEM image of the high-quality R-stacked bilayer WS2 lattice. The yellow and blue balls represent the W and S atoms, respectively.

To verify the single crystallinity of the bilayer WS2, systematic characterizations using selected area electron diffraction (SAED), polarization-dependent SHG, atomic force microscopy (AFM) and TEM were performed. The atomically-resolved TEM images and SAED patterns of 4 × 4 arrays randomly selected over the sample confirmed the alignment of the R-stacked WS2 lattice (Fig. 3e and Supplementary Fig. 8–9). Larger-scale characterizations of polarization-dependent SHG pattern, SHG mapping and AFM images at different locations on a 1 × 1 cm2 sample also confirmed the excellent alignment and absence of grain boundaries (Fig. 3f and Supplementary Fig. 10–12). Further atomic-resolved TEM images clearly verified the seamless stitching of the merged bilayer WS2 islands (Fig. 3g, h), which was consistent with the growth of monolayer TMD17,18,19,20,21,22. This technique was also demonstrated applicable for the growth of aligned bilayer WSe2 (Supplementary Fig. 13).

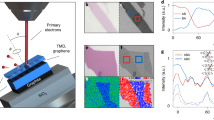

Quality of R-stacked bilayer WS2

To evaluate the quality of the obtained R-stacked bilayer WS2 films, electrical, optical and ferroelectric characterizations were performed. First, we fabricated conventional field-effect transistor (FET) devices of WS2 transferred onto SiO2/Si substrates. Remarkably to monolayer, bilayer WS2 exhibited significantly enhanced electrical performance with ~30 times greater mobility and an ~100 times greater on/off ratio at room temperature (Fig. 4a, b, the mobility distribution of a 4 × 4 device array is shown in Supplementary Fig. 14). Experimentally, the contact capacity of monolayer WS2 was very poor among the various TMD. Therefore, this remarkable improvement was likely attributed to the improved contact of bilayer WS2 alongside the intrinsically higher mobility. The mobility enhancement in bilayers was also observed before in exfoliated MoS213,14. The circularly polarized PL spectra of bilayer WS2 exhibited a much greater circular helicity than monolayer WS2 (Fig. 4c, d), indicating promising potential applications in valley electronics. This high value was likely attributed to the shorter exciton lifetime of bilayer WS230. Finally, we checked the ferroelectricity of R-stacked bilayer WS2. The absence of mirror symmetry in R-stacked bilayer WS2 induced interlayer charge transfer through hybridization between the occupied states of one layer and the unoccupied states of the other layer, generating an out-of-plane electric dipole moment and inducing interfacial ferroelectricity31,32. This intrinsic ferroelectricity could be observed in our bilayer WS2 samples (Fig. 4e, f and Supplementary Fig. 15). We also tested the stability of bilayer and monolayer WS2 samples in natural environments. After being exposed to air for two months, the monolayer WS2 suffered obvious damage, whereas the bilayer one exhibited undetectable changes, demonstrating the superior stability of R-stacked bilayer WS2 compared with monolayer one (Supplementary Fig. 16).

Electrical measurements of monolayer (a) and bilayer (b) WS2 samples at room temperature, μ is the carrier mobility. Circularly polarized photoluminescence (PL) spectra of monolayer (c) and bilayer (d) WS2 samples on a-plane sapphire, ρ is the circular helicity. The local piezo force microscopy (PFM) amplitude and phase loops during the switching process of monolayer (e) and bilayer (f) WS2 samples.

Discussion

In conclusion, we proposed a remote epitaxy mechanism for producing R-stacked bilayer TMD single crystals. Uniform bilayer growth was achieved by introducing a high flux of W at a high temperature on substrates with weak interfacial coupling to TMD. The unidirectionally R-stacked configuration was attained by the remote symmetry breaking of the atomic steps. The as-grown single-crystal R-stacked bilayer WS2 films exhibited significantly enhanced electrical, optical and ferroelectric properties. This mechanism, in principle, also has great potential for achieving stacking controlled few-layer TMD single crystals.

Methods

Growth of R-stacked bilayer WS2 single crystals on a-plane sapphire

The bilayer WS2 films were grown on a-plane sapphire in a CVD system with three temperature zones, namely, zones I–III. Sulphur (1.5 g, Alfa Aesar, 99.9%) powder was placed at the upstream end of a quartz tube and heated by an extra CVD system with one temperature zone. WO3 (400 mg, Alfa Aesar, 99.998%) powder and NaCl (60 mg, Alfa Aesar, 99.95%) were placed in zone I of the tube furnace and sapphire substrates were placed in zone III. The NaCl can effectively lower the melting point and react with WO3, resulting in much higher W source. During the growth process, the S source started to heat at 30 min and the temperature up to 160 °C within 20 min. The temperatures of zone I, zone II and zone III, were heated to 625, 625 and 975 °C in 50 min respectively, under a mixed-gas flow (Ar, 40 sccm; H2, 0-1 sccm). The pressure in the growth chamber was kept at ~120 Pa. After growth for 10 min, the whole CVD system was cooled down to room temperature under an Ar gas flow (40 sccm). To grow bilayer WS2 islands, the quantity of WO3, NaCl and S are 200 mg, 30 mg and 1 g, respectively, and the growth time is 4 min.

Device fabrications and measurements

The FETs were fabricated through a standard microfabrication process by electron beam lithography techniques on transferred WS2 on 300 nm SiO2/Si. The Au contact electrodes (~50 nm) were fabricated by an e-beam deposition system with a low vacuum of ~3 × 10−7 Pa. All the electrical measurements were carried out in a probe station (base pressure 10−4 Pa) with an Agilent semiconductor parameter analyser (B1500, high-resolution modules) at room temperature.

Characterization

-

(i)

AFM and PFM measurements were conducted using two types of instruments, specifically the Bruker Dimensional ICON and Asylum Cypher S. The details to obtain atomically-resolved images are as follows: The AFM measurements were conducted using an Asylum Cypher S system at room temperature under ambient condition. The system was set to lateral force microscopy mode. The setpoint was adjusted to 0.7 V and the scan rate was established at 40 Hz. The rapid scanning enabled the acquisition of the lateral signals from the samples. These signals were subsequently processed with a fast Fourier transform filter to obtain the atomically-resolved images of the samples.

-

(ii)

Optical measurements. Optical images were conducted with an Mshot MSX10 microscope. Raman and PL spectra were conducted on a WITec-Alpha300 Raman system with a laser excitation wavelength of 532 nm and power of ~2 mW. The circular helicity of the films was probed under an off-resonant excitation photon energy of 2.34 eV. Polarized light was generated with a super-achromatic quarter-wave plate (Thorlabs SAQWP05M-700) and the PL was analysed through the same quarter-wave plate as well as a linear polarizer. SHG mapping was obtained using the Raman system under excitation from a picosecond laser centred at 1064 nm with an average power of 200 mW (Rainbow 1064 OEM with pulse duration of 15 ps and repetition rate of 50 MHz).

-

(iii)

TEM measurements. The WS2 samples were transferred onto commercial holey carbon TEM grids (Zhongjingkeyi GIG-2010-3C). STEM experiments were performed in FEI Titan Themis G2 300 operated at 80 kV.

Computational details

Geometric optimization and energy calculations of the TMD-Al2O3 systems were carried out using density functional theory (DFT) as implemented in Vienna Ab-initio Simulation Package33,34. The exchange-correlation functions are treated by the generalized gradient approximation35 and the interaction between valence electrons and ion cores is carried out by the projected augmented wave method36. The plane-wave cutoff energy was set at 400 eV for TMD-Al2O3 systems. The dispersion-corrected DFT-D3 method was used because of its good description of long-range vdW interactions for multi-layered 2D materials. The geometries of the TMD-Al2O3 systems were relaxed until the force on each atom was less than 0.02 eV Å−1, and the energy convergence criterion of 1 × 10−4 eV was met. The Al2O3 surfaces were modelled by a periodic slab and some bottom layers were fixed to mimic the bulk, a 1 × 1 × 1 Monkhorst–Pack k-point mesh was adopted.

Data availability

The Source Data underlying the figures of this study are available with the paper. All raw data generated during the current study are available from the corresponding authors upon request. Source data are provided with this paper.

References

Ma, T. et al. Growth of bilayer MoTe2 single crystals with strong non-linear Hall effect. Nat. Commun. 13, 5465 (2022).

Lin, K. Q. et al. Ultraviolet interlayer excitons in bilayer WSe2. Nat. Nanotechnol. 19, 196–201 (2024).

Mak, K. F., Xiao, D. & Shan, J. Light-valley interactions in 2D semiconductors. Nat. Photonics 12, 451–460 (2018).

Naik, M. H. & Jain, M. Ultraflatbands and shear solitons in moire patterns of twisted bilayer transition metal dichalcogenides. Phys. Rev. Lett. 121, 266401 (2018).

Park, H. et al. Observation of fractionally quantized anomalous Hall effect. Nature 622, 74–79 (2023).

Wang, L. et al. Correlated electronic phases in twisted bilayer transition metal dichalcogenides. Nat. Mater. 19, 861–866 (2020).

Wu, F. C., Lovorn, T., Tutuc, E., Martin, I. & MacDonald, A. H. Topological insulators in twisted transition metal dichalcogenide homobilayers. Phys. Rev. Lett. 122, 086402 (2019).

Xu, F. et al. Observation of integer and fractional quantum anomalous hall effects in twisted bilayer MoTe2. Phys. Rev. X 13, 031037 (2023).

Xu, Y. et al. A tunable bilayer Hubbard model in twisted WSe2. Nat. Nanotechnol. 17, 934–939 (2022).

Zhang, Z. M. et al. Flat bands in twisted bilayer transition metal dichalcogenides. Nat. Phys. 16, 1093–1096 (2020).

Gao, Q. G. et al. Scalable high performance radio frequency electronics based on large domain bilayer MoS2. Nat. Commun. 9, 4778 (2018).

Li, X. F. et al. Rhombohedral-stacked bilayer transition metal dichalcogenides for high-performance atomically thin CMOS devices. Sci. Adv. 9, eade5706 (2023).

Liu, L. et al. Uniform nucleation and epitaxy of bilayer molybdenum disulfide on sapphire. Nature 605, 69–75 (2022).

Wang, Q. Q. et al. Layer-by-layer epitaxy of multi-layer MoS2 wafers. Natl. Sci. Rev. 9, nwac077 (2022).

Zhang, X. M. et al. Transition metal dichalcogenides bilayer single crystals by reverse-flow chemical vapor epitaxy. Nat. Commun. 10, 598 (2019).

Zheng, J. Y. et al. High-Mobility Multilayered MoS2 Flakes with Low Contact Resistance Grown by Chemical Vapor Deposition. Adv. Mater. 29, 1604540 (2017).

Fu, J. H. et al. Oriented lateral growth of two-dimensional materials on c-plane sapphire. Nat. Nanotechnol. 18, 1289–1294 (2023).

Kim, K. S. et al. Non-epitaxial single-crystal 2D material growth by geometric confinement. Nature 614, 88–94 (2023).

Li, T. T. et al. Epitaxial growth of wafer-scale molybdenum disulfide semiconductor single crystals on sapphire. Nat. Nanotechnol. 16, 1201–1207 (2021).

Wang, J. H. et al. Dual-coupling-guided epitaxial growth of wafer-scale single-crystal WS2 monolayer on vicinal a-plane sapphire. Nat. Nanotechnol. 17, 33–38 (2022).

Zheng, P. M. et al. Universal epitaxy of non-centrosymmetric two-dimensional single-crystal metal dichalcogenides. Nat. Commun. 14, 592 (2023).

Zhu, H. Y. et al. Step engineering for nucleation and domain orientation control in WSe2 epitaxy on c-plane sapphire. Nat. Nanotechnol. 18, 1295–1302 (2023).

Dumcenco, D. et al. Large-Area Epitaxial Monolayer MoS2. ACS Nano 9, 4611–4620 (2015).

Chen, L. et al. Step-edge-guided nucleation and growth of aligned WSe2 on sapphire via a layer-over-layer growth mode. ACS Nano 9, 8368–8375 (2015).

Zhu, J. D. et al. Low-thermal-budget synthesis of monolayer molybdenum disulfide for silicon back-end-of-line integration on a 200 mm platform. Nat. Nanotechnol. 18, 456–463 (2023).

Cuccureddu, F. et al. Surface morphology of c-plane sapphire (α-alumina) produced by high temperature anneal. Surf. Sci. 604, 1294–1299 (2010).

Chen, L. A. et al. Large-area single-crystal TMD growth modulated by sapphire substrates. Nanoscale 16, 978–1004 (2024).

Liu, F. et al. Disassembling 2D van der Waals crystals into macroscopic monolayers and reassembling into artificial lattices. Science 367, 903–906 (2020).

Zhou, X. et al. Strong second-harmonic generation in atomic layered GaSe. J. Am. Chem. Soc. 137, 7994–7997 (2015).

Zhu, B. R., Zeng, H. L., Dai, J. F., Gong, Z. R. & Cui, X. D. Anomalously robust valley polarization and valley coherence in bilayer WS2. P Natl Acad. Sci. USA 111, 11606–11611 (2014).

Wang, X. R. et al. Interfacial ferroelectricity in rhombohedral-stacked bilayer transition metal dichalcogenides. Nat. Nanotechnol. 17, 367–371 (2022).

Weston, A. et al. Interfacial ferroelectricity in marginally twisted 2D semiconductors. Nat. Nanotechnol. 17, 390–395 (2022).

Kresse, G. & Furthmuller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comp. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for open-shell transition metals. Phys. Rev. B 48, 13115–13118 (1993).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Acknowledgements

This work was supported by the National Key R&D Program of China (2022YFA1403503 (X.X.)), the National Natural Science Foundation of China (12322406 (X.X.), 52102043 (X.X.), 52025023 (K.L.), 51991342 (K.L.), 52021006 (K.L.), 52372046 (X.Z.) and 52102044 (X.Z.)), Guangdong Major Project of Basic and Applied Basic Research (2021B0301030002 (K.L.)), the Key R&D Program of Guangdong Province (2020B010189001 (X.X.), 2019B010931001 (K.L.), 2018B010109009 (D.Y.) and 2018B030327001 (D.Y.)), the Pearl River Talent Recruitment Program of Guangdong Province (2019ZT08C321 (X.X.)), the National Postdoctoral Program for Innovative Talents (BX20220117 (W.W.)), China Postdoctoral Science Foundation (2022M721224 (W.W.) and 2022M720208 (J.W.)), the Key Project of Science and Technology of Guangzhou (202201010383 (X.Z.)), Guangdong Basic and Applied Basic Research Foundation (2023A1515012743 (X.Z.)) and the Strategic Priority Research Program of Chinese Academy of Sciences (XDB33000000 (K.L.)). We thank the National Supercomputer Centre in Tianjin for computing support.

Author information

Authors and Affiliations

Contributions

X.X. and K.L. supervised the project. C.C., X.Z., W.L., Y.C. and J.W. conducted the sample growth, Q.G. performed the TEM experiments. C.H. performed the optical measurements. Y.R. performed the AFM experiments. Z.F. performed the electrical measurements. W.W. and F.D. performed the theoretical calculations. X.X., K.L. and W.W. wrote the article, Z.T., X.Z. and F.D. revised the manuscript. All of the authors discussed the results and comments on the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Minggang Xia and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chang, C., Zhang, X., Li, W. et al. Remote epitaxy of single-crystal rhombohedral WS2 bilayers. Nat Commun 15, 4130 (2024). https://doi.org/10.1038/s41467-024-48522-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-48522-8

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.